Wire tube condenser for heat pump systems?

A wire tube condenser plays a crucial role in heat pump systems. It consists of coiled tubing, often made from copper or aluminum, designed to efficiently transfer heat. This component helps the refrigerant release heat, enabling its transformation from gas to liquid. Its compact design and ability to maximize surface area make it ideal for various applications, including refrigeration and air conditioning.

Wire tube condensers are essential in modern heat pump systems. They enhance energy efficiency and cooling speed while maintaining cost-effectiveness. At senjun, we specialize in producing high-quality wire tube condensers. Our products support appliances like refrigerators, freezers, and dehumidifiers, ensuring reliable thermal management.

Key Takeaways

- Wire tube condensers help move heat in heat pump systems. They are great for devices like fridges and dehumidifiers.

- Their small size and energy-saving design lower electricity costs. This helps both companies and users save money.

- Wire tube condensers are strong and last a long time. They don’t break easily, so you won’t need to fix or replace them often.

- Cleaning them every 6-12 months keeps them working well. This also makes them last longer.

- Picking a trusted supplier like Senjun gives you good-quality wire tube condensers. They can be made to fit different needs.

How Wire Tube Condensers Work

Design and Structure

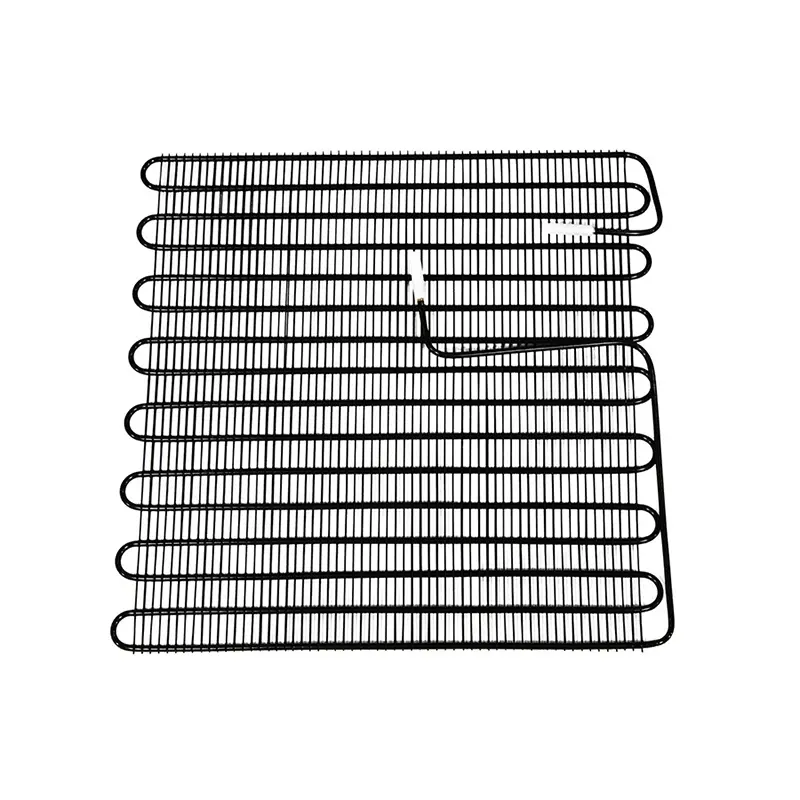

When I look at a wire tube condenser, its design immediately stands out. It consists of coiled tubes, often made from copper or aluminum, which are excellent conductors of heat. These tubes act as the main pathway for the refrigerant. Wires are welded onto the tubes, forming a mesh-like structure. This wire mesh increases the surface area, allowing the condenser to dissipate heat more effectively. The design also helps reduce vibrations caused by refrigerant flow, ensuring smoother operation.

At senjun, we focus on creating wire tube condensers with precision. By using high-quality materials and advanced manufacturing techniques, we ensure that our products deliver optimal performance. This attention to detail makes our condensers reliable for various applications, from refrigerators to heat pumps.

Heat Transfer Mechanism

The heat transfer process in a wire tube condenser is fascinating. Here’s how it works:

- The refrigerant enters the condenser as a high-pressure gas at a high temperature.

- As it flows through the coiled tubes, it releases heat to the surrounding wires.

- The wires then dissipate this heat into the air or a cooling medium, causing the refrigerant to condense into a liquid.

This phase change is crucial. It allows the refrigerant to release stored heat efficiently, preparing it for the next cycle in the heat pump system. The simplicity of this mechanism is one reason why wire tube condensers are so effective in thermal management.

Applications in Heat Pump Systems

Wire tube condensers play a vital role in heat pump systems. They are commonly used in residential and commercial heating and cooling applications. Their compact design makes them ideal for systems where space is limited. I’ve seen them used in appliances like refrigerators, freezers, and dehumidifiers, where efficient heat exchange is critical.

At senjun, we specialize in producing wire tube condensers tailored for diverse applications. Whether it’s for a medical ultra-low temperature refrigerator or a display cabinet, our products ensure reliable performance. This versatility highlights why wire tube condensers remain a popular choice in modern heat pump systems.

Benefits of Wire Tube Condensers

Cost-Effectiveness

When I think about cost-effective solutions for heat pump systems, wire tube condensers immediately come to mind. These condensers are relatively inexpensive to manufacture, which makes them an affordable choice for manufacturers of appliances like refrigerators and freezers. Their popularity in industrial applications stems from this affordability.

Another advantage lies in their efficiency. Wire tube condensers have a heat transfer efficiency that is 50% higher than plate condensers. This means they consume less energy during operation, leading to lower electricity bills. Over time, this energy-saving capability translates into significant cost reductions for both manufacturers and end-users.

At senjun, we prioritize creating wire tube condensers that deliver exceptional value. By combining affordability with high performance, our products meet the needs of diverse applications without compromising quality.

Energy Efficiency

Energy efficiency is a critical factor in heat pump systems, and wire tube condensers excel in this area. Their design maximizes heat transfer. The coiled tubes and wire mesh structure provide a large surface area, allowing the refrigerant to release heat more effectively. This efficient heat exchange enhances the overall performance of the system.

The serpentine shape of the tubes further boosts efficiency by increasing the surface area for heat removal. This design ensures that the condenser operates at peak performance, reducing energy consumption. In fact, wire tube condensers have a 50% higher coefficient of heat transfer compared to plate condensers. This improvement not only saves energy but also supports sustainable practices.

At senjun, we understand the importance of energy efficiency. Our wire tube condensers are designed to optimize heat pump performance while minimizing energy usage, making them an eco-friendly choice.

Durability and Longevity

Durability is another standout feature of wire tube condensers. I’ve seen how their robust construction ensures long-lasting performance. Made from materials like Bundy tubes and steel wires, these condensers resist wear and tear, even under demanding conditions. This durability reduces the need for frequent replacements, saving time and money.

Their design also reduces the workload on compressors, which extends the lifespan of the entire appliance. For example, in refrigerators or dehumidifiers, a reliable condenser can significantly enhance the overall durability of the system.

At senjun, we take pride in producing wire tube condensers that are built to last. Our focus on quality materials and precise manufacturing ensures that our products deliver consistent performance over time.

Simplicity in Maintenance

When I think about maintaining a heat pump system, I always appreciate how simple it is to care for a wire tube condenser. Its design makes cleaning and upkeep straightforward. The open structure of the wire mesh allows easy access to the tubes. This means I can quickly remove dust or debris that might accumulate over time. Regular cleaning ensures the condenser operates efficiently, which helps avoid unnecessary energy consumption.

Another advantage is the durability of these condensers. Their robust construction means fewer repairs or replacements are needed. I’ve noticed that this reliability significantly reduces maintenance costs over the long term. For example, in appliances like refrigerators or dehumidifiers, a durable condenser ensures consistent performance without frequent interventions.

Here’s why I find wire tube condensers easier to maintain compared to other types:

- The open design allows for quick and effective cleaning.

- Their sturdy build minimizes the need for repairs or replacements.

- Maintenance costs remain low due to their long-lasting performance.

At senjun, we prioritize creating wire tube condensers that are not only efficient but also user-friendly. Our products are designed to simplify maintenance, saving both time and money for users. Whether it’s for a medical ultra-low temperature refrigerator or a display cabinet, senjun’s condensers deliver reliable performance with minimal upkeep.

Limitations of Wire Tube Condensers

Limited Heat Transfer Capacity

Wire tube condensers work well in many applications, but their heat transfer capacity has limits. I’ve noticed that their design, while efficient, relies on natural convection. This means they depend on air movement to dissipate heat. In environments with poor airflow, their performance can drop. The coiled tubes and wire mesh structure provide a decent surface area, but they may not match the efficiency of more advanced designs like finned tube condensers in high-demand systems.

At senjun, we focus on optimizing the performance of wire tube condensers for specific uses. By using high-quality materials and precise manufacturing techniques, we ensure our products meet the needs of most applications. However, for systems requiring extremely high heat transfer rates, other condenser types might be more suitable.

Suitability for Specific Applications

Wire tube condensers excel in compact systems, but they may not fit every scenario. I’ve seen them perform best in appliances like refrigerators, freezers, and dehumidifiers. Their simple design and cost-effectiveness make them ideal for these uses. However, in industrial or large-scale systems, their capabilities might fall short. For example, systems requiring rapid heat dissipation or operating in extreme conditions might demand more specialized solutions.

At senjun, we tailor our wire tube condensers to match the requirements of various applications. Whether it’s for a medical ultra-low temperature refrigerator or a display cabinet, our products deliver reliable performance. Still, understanding the specific needs of your system is crucial when choosing the right condenser.

Challenges in Larger Systems

In larger heat pump systems, wire tube condensers face unique challenges. I’ve observed that maintaining consistent wire tension during the welding process can be difficult. Ensuring uniform weld strength across thousands of contact points is another hurdle. Thermal distortion during welding can also affect the final product. Additionally, achieving high production speeds without compromising quality remains a constant challenge.

Other issues include handling different material combinations effectively and meeting increasing production volume demands. Reducing production costs while maintaining quality is a balancing act. Minimizing material waste and ensuring worker safety add to the complexity. Managing equipment maintenance in high-output environments is equally important.

At senjun, we address these challenges with advanced manufacturing techniques and a commitment to quality. Our expertise in producing wire tube condensers ensures that even in demanding applications, our products perform reliably. By focusing on innovation and precision, we continue to meet the evolving needs of the industry.

Comparison with Other Condenser Types

Wire Tube vs. Finned Tube Condensers

When comparing wire tube condensers to finned tube condensers, I notice distinct differences in their design and performance. Wire tube condensers use coiled tubes with a wire mesh structure to maximize surface area. This design works well for compact systems like refrigerators and freezers. On the other hand, finned tube condensers feature metal fins attached to the tubes. These fins enhance heat dissipation, making them suitable for larger systems or environments requiring rapid cooling.

Wire tube condensers excel in simplicity and cost-effectiveness. Their open structure allows for easy maintenance, which I find particularly useful in residential applications. Finned tube condensers, while more efficient in high-demand systems, require more frequent cleaning due to dust accumulation between the fins. At senjun, we focus on producing wire tube condensers that balance performance and affordability, making them a reliable choice for various applications.

Wire Tube vs. Plate Condensers

The differences between wire tube condensers and plate condensers become clear when examining their features. Here’s a quick comparison:

| Feature | Wire Tube Condensers | Plate Condensers |

|---|---|---|

| Heat Transfer Coefficient | 50% higher | Lower |

| Energy Consumption | Reduced | Higher |

| Versatility | High | Moderate |

Wire tube condensers outperform plate condensers in heat transfer efficiency, with a 50% higher coefficient. This efficiency reduces energy consumption, making them more cost-effective. Their durable materials also ensure a longer lifespan. Plate condensers, while compact, may not match the versatility of wire tube condensers. I’ve seen wire tube condensers used in a wide range of appliances, from medical refrigerators to dehumidifiers, which highlights their adaptability.

Key Factors for Choosing a Condenser

Choosing the right condenser depends on several factors. I always consider both process and non-process parameters. For example, the type of condenser—whether wire tube, finned tube, or plate—plays a significant role. Temperature requirements, venting needs, and the handling of wide condensing-range mixtures also influence the decision. Unit cost and application-specific demands, such as space constraints or energy efficiency goals, are equally important.

At senjun, we understand these considerations. Our wire tube condensers are designed to meet diverse needs, offering a balance of performance, durability, and cost-effectiveness. Whether you’re selecting a condenser for a refrigerator, freezer, or heat pump system, evaluating these factors ensures optimal performance.

Suitability for Heat Pump Systems

When to Choose a Wire Tube Condenser

I always recommend wire tube condensers for systems that prioritize energy efficiency and cost-effectiveness. Their design makes them ideal for compact applications like refrigerators, freezers, and dehumidifiers. These condensers excel in environments where moderate heat transfer is sufficient. Their durability ensures long-lasting performance, even under continuous operation.

Wire tube condensers also stand out for their environmental benefits. They use recycled metals and natural refrigerants, reducing their ecological footprint. This makes them a great choice for those seeking sustainable solutions. At senjun, we specialize in creating wire tube condensers tailored to meet diverse needs. Our products combine efficiency, durability, and eco-friendliness, making them suitable for a wide range of heat pump systems.

Factors to Evaluate for Your System

When selecting a condenser, I always consider several key factors to ensure optimal performance. These include:

- Climate conditions

- Type of heat pump

- Size and capacity

- Energy efficiency

- Budget

- Noise

- Function and features

- Available space

Each factor plays a crucial role in determining the best fit for your system. For example, in colder climates, a condenser with high heat transfer efficiency is essential. In contrast, compact systems benefit from space-saving designs. At senjun, we understand these considerations and offer customizable solutions to meet specific requirements.

Examples of Ideal Use Cases

Wire tube condensers shine in various applications. I’ve seen them perform exceptionally well in residential and commercial appliances. For instance, they are commonly used in refrigerators, freezers, and medical ultra-low temperature refrigerators. Their compact design and efficient heat transfer make them perfect for display cabinets and wine coolers. Dehumidifiers and ice makers also benefit from their reliability and low maintenance needs.

At senjun, we take pride in producing wire tube condensers for these diverse applications. Our expertise ensures that each product delivers consistent performance, whether it’s for a drinking fountain or a heat pump system. This versatility highlights why wire tube condensers remain a trusted choice in the industry.

| Criteria | Description |

|---|---|

| Heat Transfer Efficiency | Wire tube condensers have a 50% higher coefficient compared to plate condensers, enhancing efficiency. |

| Durability | Made from durable materials like Bundy tubes and steel wires, ensuring long-lasting performance. |

| Environmental Impact | Use of recycled metals and natural refrigerants minimizes environmental impact. |

| Customization Options | Tailored solutions available to meet specific needs, optimizing cooling efficiency. |

By evaluating these criteria, I can confidently recommend wire tube condensers for systems that demand efficiency, durability, and sustainability.

Wire tube condensers offer efficient heat transfer and energy savings, making them essential for systems like refrigerators and HVAC units. Their durability and simple maintenance ensure long-term reliability. Custom designs tailored to specific cooling needs enhance performance and lifespan. Regular cleaning every 6-12 months keeps them running efficiently.

For heat pump systems, I recommend wire tube condensers when energy efficiency and cost-effectiveness are priorities. Their compact design suits residential and commercial applications. Choosing a reliable supplier like Senjun ensures high-quality, customized solutions. Senjun’s commitment to innovation and customer satisfaction makes them a trusted provider across industries, including refrigeration and HVAC.

FAQ

What is a wire tube condenser?

A wire tube condenser is a heat exchange device made of coiled tubes and wire mesh. It helps release heat from refrigerants in systems like refrigerators and heat pumps. Its design maximizes surface area for efficient heat transfer. At senjun, we specialize in producing high-quality wire tube condensers for various applications.

How do I maintain a wire tube condenser?

Maintaining a wire tube condenser is simple. I recommend cleaning it every 6-12 months to remove dust or debris. Use a soft brush or vacuum for cleaning. This ensures efficient performance and extends its lifespan. Senjun’s durable designs make maintenance even easier for users.

Are wire tube condensers energy-efficient?

Yes, wire tube condensers are highly energy-efficient. Their coiled tube and wire mesh design maximize heat transfer, reducing energy consumption. I’ve seen them save energy in appliances like refrigerators and dehumidifiers. Senjun’s products are designed to optimize energy efficiency while maintaining performance.

Where can I use wire tube condensers?

Wire tube condensers work well in compact systems like refrigerators, freezers, and dehumidifiers. They’re also ideal for medical ultra-low temperature refrigerators and display cabinets. At senjun, we create condensers tailored for diverse applications, ensuring reliable performance across industries.

Why choose senjun for wire tube condensers?

Senjun stands out for its expertise in wire tube condenser production. We use high-quality materials and advanced techniques to ensure durability and efficiency. Our products support various appliances, from ice makers to heat pumps. With senjun, you get reliable, customized solutions for your cooling needs.