Why Copper Fin Heat Exchangers Are Vital for Industrial Cooling

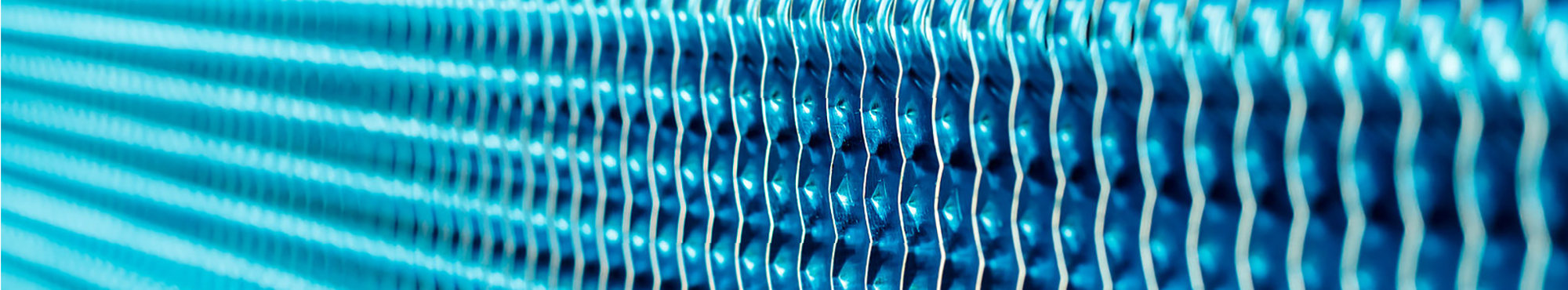

Industrial cooling systems demand efficiency, durability, and reliability. A copper fin heat exchanger meets these demands with its exceptional thermal conductivity and resistance to corrosion. Its ability to inhibit bacterial and fungal growth ensures cleaner surfaces and longer service life. Industries worldwide rely on this technology to reduce energy consumption and operational costs.

For example, copper fins enhance heat transfer by increasing surface area, enabling faster temperature regulation. Compared to aluminum, copper offers superior corrosion resistance, especially in humid or salty environments. This makes it indispensable for critical applications. At SENJUN, we specialize in crafting copper aluminum fin heat exchangers, ensuring unmatched performance for industries like HVAC, automotive, and power generation.

Key Takeaways

- Copper fin heat exchangers move heat well, saving energy and time.

- They resist rust, making them great for tough conditions and lasting longer.

- Using copper fin heat exchangers cuts costs and saves energy, helping businesses and nature.

- Copper is easy to recycle, making it good for the planet.

- Cleaning the fins often keeps them working better and lasting longer.

The Unique Properties of Copper Fin Heat Exchangers

Exceptional Thermal Conductivity

When it comes to thermal conductivity, copper stands out as one of the most efficient materials. I’ve seen firsthand how copper fin heat exchangers excel in transferring heat quickly and effectively. Copper has a thermal conductivity of 231 Btu/(hr-ft-F), which is second only to silver among metals. This value is 60% higher than aluminum and nearly 30 times greater than stainless steel. Such superior conductivity ensures that heat transfer processes occur with minimal energy loss, making copper fin heat exchangers an ideal choice for industrial cooling.

To put this into perspective, here’s a comparison of thermal conductivity values for commonly used metals:

| Metal | Thermal conductivity (Btu/(hr-ft-F)) |

|---|---|

| Silver | 247.87 |

| Copper | 231 |

| Aluminum | 136 |

| Stainless Steel | 8.1 |

This remarkable property allows SENJUN’s copper aluminum fin heat exchangers to deliver unmatched performance in industries like HVAC, power generation, and manufacturing.

Corrosion Resistance in Harsh Environments

Copper fin heat exchangers also shine in their ability to resist corrosion. I’ve observed how they perform exceptionally well in humid and salty environments, where other materials like aluminum often fail. Copper’s natural resistance to corrosion ensures that these heat exchangers maintain their efficiency over time. Additionally, designs like SENJUN’s incorporate advanced coatings, such as nano anti-corrosion layers, to further enhance durability. This feature is particularly valuable in industries like chemical processing and marine applications, where exposure to corrosive substances is common.

Durability and Longevity

Durability is another key advantage of copper fin heat exchangers. I’ve noticed that their robust construction allows them to withstand harsh industrial conditions, including thermal expansion and pressure fluctuations. Copper’s resistance to scaling and fouling reduces maintenance needs, minimizing downtime and operational costs. For example:

- Copper fin heat exchangers endure extreme refinery conditions without compromising performance.

- They require less frequent cleaning due to their resistance to scaling.

- Their long lifespan makes them a cost-effective solution for industrial cooling.

At SENJUN, we take pride in crafting copper aluminum fin heat exchangers that combine these properties with innovative designs. Our products, including the SENJUN Condenser, are built to last, ensuring reliable performance in demanding environments.

Ningbo Senjun New Materials Co., Ltd. specializes in the research and production of copper aluminum fin heat exchangers for applications such as refrigerators, freezers, and dehumidifiers. Our commitment to quality and innovation makes us a trusted partner for industries worldwide.

Sustainability and Recyclability

Sustainability has become a critical factor in industrial operations. I’ve observed how copper fin heat exchangers contribute significantly to eco-friendly practices. Copper, as a material, is not only durable but also highly recyclable. This makes it an excellent choice for industries aiming to reduce their environmental footprint.

One of the standout features of copper is its ability to be recycled without losing its properties. In fact, nearly 80% of all copper ever mined is still in use today. This remarkable statistic highlights the material’s longevity and its role in promoting a circular economy. When industries choose copper fin heat exchangers, they actively support sustainable practices by reducing waste and conserving natural resources.

♻️ Did you know? Recycling copper requires up to 85% less energy compared to primary copper production. This energy efficiency translates to lower greenhouse gas emissions, making copper an environmentally responsible choice.

At SENJUN, sustainability is at the core of our operations. Our copper aluminum fin heat exchangers are designed with both performance and environmental impact in mind. By using high-quality copper, we ensure that our products not only deliver exceptional thermal efficiency but also align with global sustainability goals. The recyclability of our materials allows industries to minimize waste at the end of the product lifecycle.

I’ve also noticed how copper’s durability reduces the need for frequent replacements. This longevity further enhances its sustainability by lowering the demand for new raw materials. Industries using SENJUN’s heat exchangers benefit from both cost savings and a reduced carbon footprint.

Ningbo Senjun New Materials Co., Ltd. specializes in the development of copper aluminum fin heat exchangers for applications like refrigerators, freezers, and dehumidifiers. Our commitment to innovation and sustainability makes us a trusted partner for industries worldwide.

🌍 Tip: Choosing copper fin heat exchangers is not just a smart business decision—it’s a step toward a greener future.

Comparing Copper Fin Heat Exchangers to Alternatives

Copper vs. Aluminum: Performance and Durability

I’ve observed that copper fin heat exchangers consistently outperform aluminum counterparts in industrial cooling systems. Copper’s superior corrosion resistance makes it ideal for humid or salty environments, where aluminum tends to degrade more quickly. This resistance ensures a longer lifespan and reduces maintenance needs, which is critical for industries aiming to minimize downtime.

Durability is another area where copper excels. Aluminum, while lightweight, is more prone to damage under high pressure or thermal stress. Copper’s robust nature allows it to withstand harsh industrial conditions without compromising performance. For example, SENJUN’s copper aluminum fin heat exchangers are designed to endure demanding environments, ensuring reliable operation over time.

Copper vs. Stainless Steel: Cost and Efficiency

When comparing copper to stainless steel, I’ve noticed that each material has unique advantages. Copper offers unmatched thermal conductivity, which translates to higher energy efficiency and lower operational costs. This efficiency makes copper fin heat exchangers a cost-effective choice for industries focused on reducing energy consumption.

Stainless steel, on the other hand, is known for its exceptional durability and corrosion resistance. While it may lower replacement costs over time, its thermal conductivity is significantly lower than copper. This means stainless steel heat exchangers often require more energy to achieve the same level of cooling. At SENJUN, we prioritize copper for its ability to deliver both efficiency and long-term reliability, making it the preferred material for industrial cooling applications.

Why Copper Outperforms in Industrial Applications

Copper’s unique properties make it the material of choice for demanding industrial applications. Its superior thermal conductivity ensures efficient heat transfer, while its corrosion resistance and durability provide long-lasting performance. I’ve seen how these qualities allow copper fin heat exchangers to excel in industries like power generation, chemical processing, and HVAC.

Here’s a breakdown of copper’s key advantages:

| Property | Importance | Applications | Example |

|---|---|---|---|

| Superior Electrical and Thermal Conductivity | Reduces energy loss and overheating. | Heat exchangers, electrical wiring. | SENJUN Condenser used in industrial cooling systems. |

| Corrosion and Wear Resistance | Extends lifespan in harsh environments. | Marine hardware, chemical processing. | Copper-nickel alloys in offshore piping. |

| High Strength and Durability | Withstands high-load and high-pressure conditions. | Industrial machinery, aerospace components. | Aluminum bronze in heavy machinery. |

| Workability and Machinability | Enables cost-effective production and customization. | Precision devices, industrial equipment. | Brass used in plumbing components. |

At SENJUN, we leverage these properties to create innovative solutions like the SENJUN Condenser. This product combines copper’s inherent advantages with advanced designs to meet the rigorous demands of modern industries. Ningbo Senjun New Materials Co., Ltd. specializes in the development of copper aluminum fin heat exchangers for applications such as refrigerators, freezers, and dehumidifiers. Our commitment to quality and innovation ensures that our products remain a trusted choice for professionals worldwide.

The Role of Copper Fin Heat Exchangers in Industrial Cooling

Enhancing Heat Transfer Efficiency

I’ve observed how copper fin heat exchangers excel in enhancing heat transfer efficiency. Copper’s high thermal conductivity, combined with the increased surface area provided by fins, allows for rapid and consistent heat exchange. This design ensures that systems achieve desired temperatures quickly and maintain them with minimal energy loss. For instance, copper has a thermal conductivity of 231 Btu/(hr-ft-F), significantly outperforming materials like aluminum and stainless steel.

| Material | Thermal Conductivity (Btu/(hr-ft-F)) |

|---|---|

| Copper | 231 |

| Aluminum | 60% less than copper |

| Stainless Steel | 30 times less than copper |

The fins on these heat exchangers further enhance performance by increasing the surface area for heat dissipation. This feature is particularly beneficial in compact systems where space is limited. I’ve seen how this combination of properties makes copper fin heat exchangers indispensable for industries requiring precise temperature control, such as HVAC and power generation.

✅ Tip: Regular cleaning of fins and tubing ensures optimal heat transfer efficiency.

Reducing Energy Consumption

Copper fin heat exchangers contribute significantly to reducing energy consumption in industrial cooling systems. Their superior thermal conductivity enables efficient heat transfer, allowing systems to reach and maintain target temperatures faster. This efficiency minimizes the energy required for operation, leading to lower utility costs.

- Finned tubes increase the surface area for heat transfer.

- Rapid heat exchange reduces the workload on cooling systems.

- Consistent temperature regulation enhances overall system efficiency.

At SENJUN, we design copper aluminum fin heat exchangers that prioritize energy efficiency. These products help industries achieve their sustainability goals while maintaining high performance. I’ve noticed how this focus on efficiency aligns with the growing demand for eco-friendly industrial solutions.

Ensuring Long-Term Reliability

Durability is a hallmark of copper fin heat exchangers. Copper’s natural resistance to corrosion ensures longevity, even in harsh environments. Unlike aluminum, which degrades faster in humid or salty conditions, copper maintains its structural integrity over time. This reliability reduces maintenance needs and extends the lifespan of the equipment.

- Superior corrosion resistance minimizes wear and tear.

- Resistance to galvanic corrosion ensures durability in industrial settings.

- Reduced maintenance needs lower operational costs.

To ensure optimal performance, I recommend regular maintenance practices such as cleaning fins, inspecting for corrosion, and monitoring for leaks. These steps help maintain the reliability of copper fin heat exchangers, making them a cost-effective choice for industries worldwide.

Ningbo Senjun New Materials Co., Ltd. specializes in the research, development, and production of copper aluminum fin heat exchangers. Our products, including the SENJUN Condenser, are designed to deliver exceptional performance and durability in applications such as refrigerators, freezers, and dehumidifiers. By choosing SENJUN, industries can rely on innovative solutions that combine efficiency, reliability, and sustainability.

Lowering Maintenance Costs

I’ve seen how copper fin heat exchangers significantly reduce maintenance costs in industrial cooling systems. Their durability and resistance to corrosion minimize the need for frequent repairs or replacements. This reliability ensures that industries can focus on operations without worrying about unexpected equipment failures.

Copper’s natural properties play a key role in lowering maintenance expenses. Its resistance to scaling and fouling reduces the buildup of deposits that often hinder performance. This means fewer cleaning cycles and less downtime for maintenance. For example, industries using SENJUN’s copper aluminum fin heat exchangers benefit from extended intervals between servicing, which translates to cost savings over time.

💡 Tip: Regular inspections and cleaning of fins can further enhance the lifespan of your heat exchanger.

I’ve noticed that SENJUN’s innovative designs take maintenance efficiency to the next level. The SENJUN Condenser, for instance, features a nano anti-corrosion coating that protects against moisture, oxygen, and acidic gases. This advanced coating prevents surface degradation, ensuring the equipment remains in optimal condition even in harsh environments. As a result, industries experience fewer breakdowns and lower repair costs.

Here’s how copper fin heat exchangers help reduce maintenance costs:

- Corrosion Resistance: Copper’s durability minimizes wear and tear.

- Scaling Prevention: Reduced deposit buildup lowers cleaning frequency.

- Advanced Coatings: SENJUN’s nano anti-corrosion layer enhances longevity.

- Fewer Replacements: Long-lasting materials reduce the need for new equipment.

At Ningbo Senjun New Materials Co., Ltd., we specialize in crafting copper aluminum fin heat exchangers for applications like refrigerators, freezers, and dehumidifiers. Our commitment to quality ensures that our products, such as the SENJUN Condenser, deliver exceptional performance while keeping maintenance costs low. Investing in SENJUN solutions means choosing reliability and efficiency for the long term.

✅ Note: Lower maintenance costs not only save money but also improve operational efficiency by reducing downtime.

Real-World Applications of Copper Fin Heat Exchangers

Applications in Power Plants

Copper fin heat exchangers play a critical role in power plants, ensuring efficient and reliable operations. I’ve observed their widespread use in various applications, such as finned tubes in boilers that dissipate excess heat to maintain optimal performance. Air-cooled heat exchangers also rely on copper fins for effective heat transfer, which is essential for cooling systems in power generation.

One of the most impressive uses of these heat exchangers is in waste heat recovery for gas turbines. This process not only enhances overall efficiency but also reduces emissions, contributing to a more sustainable energy sector. Here’s a quick overview of their applications and benefits:

| Application | Benefits |

|---|---|

| Fossil and nuclear power plants | Efficient heat transfer and durability due to copper's thermal conductivity |

| Utility power plants | Utilization in surface condensers, heaters, and coolers for optimal operation |

| Desalination plants | Effective in managing heat in water treatment processes |

At Ningbo Senjun New Materials Co., Ltd., we specialize in crafting copper aluminum fin heat exchangers, including the SENJUN Condenser, which is designed to meet the rigorous demands of power plants. Its advanced features, such as nano anti-corrosion coating and innovative runner design, make it a reliable choice for these critical applications.

Use in Chemical Processing Industries

In chemical processing industries, copper fin heat exchangers address some of the most challenging operational conditions. High temperatures, fluctuating pressures, and corrosive environments are common in this sector. I’ve seen how these heat exchangers excel in managing such challenges due to copper’s exceptional thermal conductivity and natural resistance to corrosion.

The fins on these exchangers increase the surface area for heat transfer, optimizing energy use and reducing costs. For example, SENJUN’s copper aluminum fin heat exchangers are engineered to maintain performance even in harsh conditions. This makes them ideal for applications like cooling chemical reactors or managing heat in distillation processes. By ensuring rapid and efficient heat exchange, these systems help industries achieve higher productivity while minimizing energy consumption.

Success Stories from Manufacturing Facilities

Manufacturing facilities worldwide rely on copper fin heat exchangers to maintain precise temperature control and ensure operational efficiency. I’ve come across numerous success stories where these systems have transformed industrial processes. For instance, in electronic chip manufacturing, SENJUN Condensers regulate circulating water temperatures to safeguard sensitive components from overheating. Their nano anti-corrosion coating also protects against moisture and impurities, ensuring long-term reliability.

In the food and beverage industry, SENJUN Condensers create clean, low-temperature environments that extend product shelf life. Beverage filling workshops benefit from their ability to filter and cool air, maintaining strict hygiene standards. These examples highlight how SENJUN’s innovative designs meet the diverse needs of modern manufacturing.

Ningbo Senjun New Materials Co., Ltd. continues to lead the way in developing copper aluminum fin heat exchangers for applications like refrigerators, freezers, and dehumidifiers. Our commitment to quality and innovation ensures that industries can rely on our products for exceptional performance and durability.

The SENJUN Condenser: A Case Study

The SENJUN Condenser stands out as a prime example of innovation and reliability in industrial cooling. I’ve seen how this product combines advanced engineering with high-quality materials to deliver exceptional performance across various industries. Its design addresses the unique challenges of modern industrial environments, making it a trusted choice for professionals worldwide.

Key Features of the SENJUN Condenser

The SENJUN Condenser incorporates several cutting-edge features that enhance its efficiency and durability:

- Composite Sleeve Design: This innovative structure ensures effective heat exchange by maintaining turbulent fluid flow, even at lower rates.

- Nano Anti-Corrosion Coating: This advanced coating protects against moisture, oxygen, and acidic gases, ensuring long-term reliability.

- Versatile Tube Sizes: With outer diameters ranging from 7mm to 15.88mm, the condenser adapts to diverse operational needs.

- Corrugated Plate Shape: This unique design maximizes heat transfer efficiency by increasing the surface area for heat exchange.

💡 Tip: The SENJUN Condenser’s nano anti-corrosion coating significantly reduces maintenance needs, saving both time and costs.

Real-World Applications

I’ve observed the SENJUN Condenser excel in various industrial settings. In electronic chip manufacturing, it regulates water temperature to protect sensitive components. In the food and beverage industry, it ensures clean, temperature-controlled environments that extend product shelf life. Power plants also benefit from its ability to cool exhaust steam and prevent overheating in critical equipment.

| Industry | Application |

|---|---|

| Electronics | Temperature regulation for chip manufacturing processes. |

| Food and Beverage | Air cooling and filtration in beverage filling workshops. |

| Power Generation | Cooling exhaust steam and air in turbines and transformers. |

Why Choose SENJUN?

Ningbo Senjun New Materials Co., Ltd. specializes in the research, development, and production of copper aluminum fin heat exchangers. I’ve seen how their commitment to quality and innovation ensures that products like the SENJUN Condenser meet the highest industry standards. Whether for refrigerators, freezers, or industrial cooling systems, SENJUN delivers solutions that professionals trust.

✅ Note: Investing in the SENJUN Condenser means choosing a product designed for efficiency, durability, and sustainability.

Copper fin heat exchangers remain indispensable for industrial cooling due to their exceptional thermal conductivity, durability, and cost-effectiveness. Their high thermal efficiency ensures rapid heat transfer, reducing energy consumption and operational costs. The compact design allows for efficient cooling in limited spaces, making them ideal for modern industrial systems. Additionally, their corrosion resistance and versatility across applications enhance reliability and adaptability in demanding environments.

Industries benefit economically from these systems through improved energy efficiency and reduced greenhouse gas emissions. For example, they are widely used in power plants, chemical processing facilities, and desalination plants, where performance and longevity are critical. Investing in advanced solutions like the SENJUN Condenser ensures long-term reliability and cost savings. Ningbo Senjun New Materials Co., Ltd. specializes in developing copper aluminum fin heat exchangers for diverse applications, offering innovative and sustainable cooling solutions.

🌟 Tip: Choosing a copper fin heat exchanger is not just a technical decision—it’s a strategic investment in efficiency and sustainability.

FAQ

What makes copper fin heat exchangers better than other materials?

Copper fin heat exchangers excel due to their superior thermal conductivity, corrosion resistance, and durability. I’ve seen how they outperform aluminum and stainless steel in industrial cooling applications. SENJUN’s innovative designs further enhance these advantages, ensuring reliable and efficient performance across diverse industries.

How does the SENJUN Condenser improve industrial cooling efficiency?

The SENJUN Condenser uses a composite sleeve design and corrugated plates to maximize heat transfer. Its nano anti-corrosion coating ensures durability, even in harsh environments. I’ve noticed how these features reduce energy consumption and maintenance costs, making it a top choice for industrial cooling.

Are copper fin heat exchangers environmentally friendly?

Yes, copper is highly recyclable and retains its properties after recycling. Nearly 80% of all mined copper remains in use today. SENJUN prioritizes sustainability by designing copper aluminum fin heat exchangers that align with global eco-friendly goals, reducing waste and conserving resources.

What industries benefit most from SENJUN’s copper fin heat exchangers?

SENJUN’s copper aluminum fin heat exchangers serve industries like power generation, chemical processing, and food and beverage. I’ve observed their effectiveness in applications such as cooling turbines, regulating water temperatures, and maintaining clean environments in beverage production facilities.

Why should I choose SENJUN for industrial cooling solutions?

Ningbo Senjun New Materials Co., Ltd. specializes in copper aluminum fin heat exchangers and wire tube condensers. Our products, including the SENJUN Condenser, combine advanced technology with robust materials. I’ve seen how they deliver exceptional performance, durability, and energy efficiency for industries worldwide.