What are the key factors to consider when choosing a copper tube aluminum fin heat exchanger?

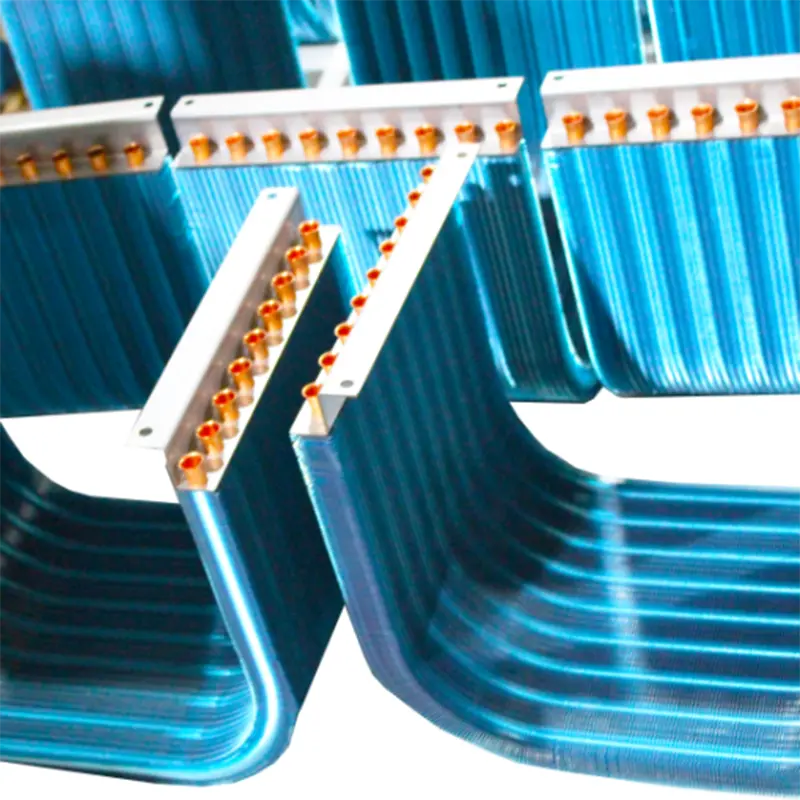

Selecting the right copper tube aluminum fin heat exchanger ensures optimal performance and long-term value. These exchangers excel in applications like HVAC systems, automotive cooling, and industrial processes due to their energy efficiency and lightweight design. The combination of copper and aluminum offers exceptional heat transfer, durability, and corrosion resistance.

At Ningbo Senjun New Materials Co., Ltd., I’ve seen how their expertise in producing high-quality heat exchangers supports industries like refrigeration, medical cooling, and dehumidification. Their commitment to innovation ensures reliable solutions tailored to diverse needs.

Key Takeaways

- Check how well it transfers heat. Copper tubes and aluminum fins work together to move heat better. This improves cooling by 5.5% and heating by 6.5%.

- Look at material quality. Copper is strong, and aluminum is light. Together, they make a durable heat exchanger that doesn’t rust and needs little care.

- Think about where it will be used. These heat exchangers can be used in HVAC systems, fridges, and medical coolers. They work well for many needs.

- Consider the cost. They may cost more at first, but they save money later with less upkeep and better energy use.

- Check for custom designs. Special designs help them work best in different places. This ensures they meet specific needs.

Performance and Efficiency

Heat Transfer Efficiency

I’ve always found that heat transfer efficiency is a critical factor when evaluating a copper tube aluminum fin heat exchanger. This type of heat exchanger stands out due to its ability to transfer heat more effectively than alternatives like all-aluminum systems. The combination of copper tubes and aluminum fins enhances heat dissipation, ensuring optimal performance in demanding applications.

For instance, copper’s high thermal conductivity allows it to transfer heat quickly, while aluminum fins provide efficient heat dissipation. Together, they create a system that is both compact and powerful. Compared to aluminum heat exchangers, this combination increases cooling capacity by 5.5% and heating capacity by 6.5%. These measurable improvements make it a reliable choice for industries requiring consistent thermal performance.

Thermal Conductivity of Copper and Aluminum

The thermal conductivity of the materials used in a heat exchanger directly impacts its efficiency. Copper and aluminum are excellent choices due to their superior thermal properties. Copper, with a thermal conductivity of 231 Btu/(hr-ft-F), outperforms aluminum, which has a value of 136 Btu/(hr-ft-F). This significant difference highlights why copper tubes are preferred for heat transfer.

Aluminum, on the other hand, complements copper by offering lightweight and cost-effective fins. This combination balances performance and affordability. I’ve seen how this pairing ensures that the heat exchanger delivers consistent results, even in challenging environments like medical ultra-low temperature refrigerators or industrial dehumidifiers.

Energy Savings and Operational Benefits

Energy efficiency is another area where copper tube aluminum fin heat exchangers excel. By improving heat transfer and reducing energy loss, these systems help lower operational costs. For example, ACC (Al-Cu composed) heat exchangers achieve a 5.6% increase in the coefficient of performance (COP) in cooling mode compared to conventional systems. They also save up to 63% in costs while reducing copper usage by 71.86%.

At Ningbo Senjun New Materials Co., Ltd., I’ve seen how their innovative designs maximize energy savings for applications like refrigerators, freezers, and ice makers. Their commitment to quality ensures that these heat exchangers not only perform efficiently but also provide long-term value for customers.

Material Quality and Durability

Properties of Copper and Aluminum

I’ve always appreciated the unique properties of copper and aluminum in heat exchangers. Copper offers excellent thermal conductivity and durability, making it a reliable choice for heat transfer. Aluminum, on the other hand, is lightweight and cost-effective. Together, they create a balance of performance and affordability.

Copper’s resistance to oxidation ensures it maintains its efficiency over time. Aluminum complements this by forming a protective oxide layer, which prevents corrosion. This combination enhances the durability of a copper tube aluminum fin heat exchanger, making it suitable for demanding applications like medical ultra-low temperature refrigerators and industrial dehumidifiers.

Corrosion Resistance

Corrosion resistance plays a vital role in the longevity of heat exchangers. Copper and aluminum excel in this area, but they perform differently in various environments. Copper rarely corrodes unless exposed to specific chemical contaminants. It often requires coatings only in chemically aggressive conditions. Aluminum, while durable, is more prone to corrosion in humid environments.

| Metal | Corrosion Resistance | Oxide Layer Characteristics | Performance in Polluted Environments |

|---|---|---|---|

| Aluminum | High | Strong, thin, clear, self-healing, impermeable to fluids | Superior; oxide layer reforms quickly |

| Copper-Brass | Moderate | Greenish, slower to form, less strong, requires additional protection (e.g., paint) | Weaker; more susceptible to pollutants and corrosion |

At Ningbo Senjun New Materials Co., Ltd., I’ve seen how their expertise ensures that their copper tube aluminum fin heat exchangers resist corrosion effectively. This makes them a dependable choice for applications like refrigerators and freezers.

Lifespan and Maintenance Requirements

The lifespan of a heat exchanger depends on the quality of its materials. Copper’s resistance to corrosion and oxidation significantly extends its durability. Aluminum’s protective oxide layer also contributes to its longevity. Together, they create a system that requires minimal maintenance.

I’ve noticed that corrosion impacts both performance and lifespan. Materials must resist corrosion from hot and cold fluids to maintain efficiency. With proper care, a copper tube aluminum fin heat exchanger can last for years, reducing the need for frequent replacements. Senjun’s products stand out for their durability and low maintenance requirements, ensuring long-term value for customers.

Application and Compatibility

Matching the Heat Exchanger to Specific Applications

I’ve noticed that copper tube aluminum fin heat exchangers are incredibly versatile. They find applications in both residential and industrial settings. For example, they are commonly used in large commercial HVAC systems and residential air conditioning units. Their adaptability makes them suitable for various heat transfer needs.

In data centers, these heat exchangers efficiently manage the heat generated by servers. Their ability to transfer and dissipate heat ensures stable performance, even in high-demand environments. I’ve seen how Ningbo Senjun New Materials Co., Ltd. customizes these heat exchangers for specific applications like refrigerators, freezers, and medical ultra-low temperature refrigerators. This flexibility ensures that the product meets the unique demands of each industry.

Operating Conditions (Temperature, Pressure, etc.)

Operating conditions play a crucial role in the performance of a heat exchanger. I always consider factors like temperature and pressure when evaluating compatibility. Copper tube aluminum fin heat exchangers perform well across a wide range of temperatures. Copper’s high thermal conductivity ensures efficient heat transfer, even in extreme conditions.

These heat exchangers also handle varying pressure levels effectively. The combination of copper and aluminum provides the strength needed to withstand high-pressure environments. For instance, in ice makers or dehumidifiers, they maintain consistent performance under demanding conditions. Ningbo Senjun’s expertise ensures their products are designed to excel in such challenging scenarios.

System Requirements and Integration

Integrating a heat exchanger into an existing system requires careful consideration. I’ve found that copper tube aluminum fin heat exchangers offer several advantages in this regard. Their lightweight design simplifies installation and reduces structural strain. The compact structure is ideal for applications where space is limited, such as data centers.

These heat exchangers also provide excellent durability and corrosion resistance. Copper’s natural resistance to corrosion and aluminum’s protective oxide layer ensure reliability in harsh environments. Customizable designs allow seamless integration into various heating and cooling systems. At Senjun, I’ve seen how their innovative solutions meet diverse system requirements, from display cabinets to wine coolers.

Ningbo Senjun New Materials Co., Ltd. continues to lead in producing high-quality heat exchangers. Their commitment to innovation and customization ensures compatibility with a wide range of applications, delivering reliable performance every time.

Cost Considerations

Initial Investment

When evaluating a copper tube aluminum fin heat exchanger, I always consider the initial investment. These heat exchangers often require a higher upfront cost compared to other options. However, the combination of copper and aluminum ensures superior performance and durability. Copper’s excellent thermal conductivity and aluminum’s lightweight design make this investment worthwhile.

I’ve noticed that the use of small-diameter copper tubes reduces material usage, which helps lower manufacturing costs. This design innovation balances the initial expense with long-term savings. At Ningbo Senjun New Materials Co., Ltd., their focus on efficient production methods ensures competitive pricing without compromising quality.

Maintenance and Repair Costs

Maintenance and repair costs play a significant role in the overall expense of a heat exchanger. I’ve found that copper tube aluminum fin heat exchangers require minimal upkeep. Copper’s natural resistance to corrosion reduces the need for frequent maintenance. Aluminum’s protective oxide layer further enhances durability, ensuring fewer repairs over time.

For example, I’ve seen how these heat exchangers maintain their efficiency even in demanding environments like medical ultra-low temperature refrigerators. Their robust design minimizes downtime and repair expenses. Senjun’s commitment to quality ensures their products deliver reliable performance with reduced maintenance needs.

Long-Term Value and ROI

The long-term return on investment (ROI) for a copper tube aluminum fin heat exchanger is impressive. These systems offer:

- Durability and a long service life, reducing replacement frequency.

- Lower maintenance costs due to corrosion resistance.

- Cost savings from the use of small-diameter copper tubes, which reduce material usage.

I’ve observed how these factors contribute to significant savings over time. For instance, the reduced need for repairs and replacements ensures consistent performance and lower operational costs. At Senjun, their innovative designs maximize ROI by delivering reliable, energy-efficient solutions for applications like refrigerators, freezers, and dehumidifiers.

Ningbo Senjun New Materials Co., Ltd. continues to lead the industry with their high-quality copper tube aluminum fin heat exchangers. Their expertise ensures customers receive products that balance cost-effectiveness with exceptional performance.

Design and Customization Options

Size and Configuration

I’ve noticed that size and configuration play a crucial role in the performance of a copper tube aluminum fin heat exchanger. These heat exchangers come in various standard options, making it easier to find a solution that fits specific needs. For example, copper and stainless steel options are widely available in standard tube fin configurations. Materials like aluminum, nickel, and cupronickel offer customizable options tailored to unique environmental requirements.

| Material | Options |

|---|---|

| Copper | Standard tube fin heat exchanger options available |

| Stainless Steel | Standard tube fin heat exchanger options available |

| Aluminum, Nickel, Cupronickel | Customizable based on environmental needs |

This variety ensures that the heat exchanger can meet the demands of different industries, from refrigeration to industrial cooling. At Ningbo Senjun New Materials Co., Ltd., I’ve seen how their expertise ensures customers receive the right size and configuration for their applications.

Customization for Unique Needs

Every application has unique requirements, and I’ve found that customization is essential for achieving optimal performance. For instance, some industries require heat exchangers that can withstand extreme temperatures or high-pressure conditions. Others may need compact designs for space-constrained environments.

Ningbo Senjun New Materials Co., Ltd. excels in offering tailored solutions. Their ability to customize copper tube aluminum fin heat exchangers ensures compatibility with specialized applications like medical ultra-low temperature refrigerators and wine cabinets. This flexibility allows businesses to achieve efficient heat transfer while meeting their specific operational needs.

Ease of Installation and Adaptability

I’ve always appreciated how easy it is to install and adapt copper tube aluminum fin heat exchangers. Their lightweight design simplifies the installation process, reducing labor costs and time. Compact configurations make them ideal for tight spaces, such as in display cabinets or dehumidifiers.

These heat exchangers also integrate seamlessly into existing systems. Their robust construction ensures reliable performance, even in demanding environments. At Senjun, I’ve seen how their innovative designs enhance adaptability, making their products a dependable choice for a wide range of applications.

Ningbo Senjun New Materials Co., Ltd. continues to lead the industry with their focus on quality and customization. Their commitment to meeting diverse customer needs ensures their heat exchangers deliver exceptional performance and long-term value.

About Ningbo Senjun New Materials Co., Ltd.

Expertise in Copper Tube Aluminum Fin Heat Exchangers

Ningbo Senjun New Materials Co., Ltd. has established itself as a leader in the field of copper tube aluminum fin heat exchangers. I’ve seen how their dedication to research, development, and production sets them apart. Their focus on quality, customization, and technological innovation ensures that every product meets the highest standards. They use advanced manufacturing techniques to create heat exchangers that deliver exceptional performance and reliability. This expertise allows them to cater to a wide range of industries, providing solutions tailored to specific needs.

Applications in Refrigerators, Freezers, and More

The versatility of Senjun’s products never ceases to amaze me. Their copper tube aluminum fin heat exchangers serve a variety of industries and applications. Here’s a quick look at where their products excel:

| Industry/Application |

|---|

| Refrigerators |

| Freezers |

| Drinking fountains |

| Display cabinets |

| Wine cabinets |

| Medical ultra-low temperature refrigerators |

| Ice makers |

| Dehumidifiers |

This broad application range highlights their ability to adapt to different operational requirements. Whether it’s a medical ultra-low temperature refrigerator or a wine cabinet, Senjun’s heat exchangers consistently deliver efficient and reliable performance.

Commitment to Quality and Innovation

Senjun’s commitment to quality is evident in every aspect of their manufacturing process. They strictly adhere to international quality standards, such as ISO9001 and ISO/TS16949 certifications. Their products also meet ISO14000 environmental management standards and hold ROHS certification. I’ve observed how their assembly lines are designed for efficiency and precision. Specialized machines ensure accurate assembly, while rigorous quality control checks, including pressure testing and visual inspections, guarantee defect-free products.

| Quality Assurance Measure | Description |

|---|---|

| Adherence to Standards | Strictly follows international quality standards to ensure product excellence. |

| Comprehensive Inspections | Conducts inspections at various stages of production to maintain quality. |

| High-Quality Materials | Utilizes high-quality raw materials and advanced production equipment. |

Senjun’s innovative approach doesn’t stop at quality assurance. They continuously invest in new technologies to enhance their products. This dedication to innovation ensures that their copper tube aluminum fin heat exchangers remain at the forefront of the industry, providing customers with cutting-edge solutions.

Choosing the right copper tube aluminum fin heat exchanger involves evaluating performance, material quality, application compatibility, cost, and design. Copper tubes with aluminum fins offer excellent durability and corrosion resistance, ensuring longevity even in harsh environments. Their smooth surfaces make cleaning easy, maintaining optimal heat transfer efficiency.

Consulting experts like Ningbo Senjun New Materials Co., Ltd. simplifies the selection process. Their customizable services, adherence to international quality standards, and competitive pricing ensure reliable solutions. With advanced technology, experienced engineers, and a commitment to innovation, Senjun consistently delivers high-quality products for diverse applications.

I’ve seen how Senjun’s expertise and dedication make them a trusted choice for industries like refrigeration, medical cooling, and dehumidification.

FAQ

What makes copper tube aluminum fin heat exchangers more efficient than other types?

I’ve found that the combination of copper’s high thermal conductivity and aluminum’s lightweight fins ensures superior heat transfer. This pairing optimizes energy efficiency and reduces operational costs, making it a preferred choice for demanding applications.

Can these heat exchangers handle extreme temperatures?

Yes, they can. Copper’s excellent thermal properties allow it to perform efficiently in both high and low temperatures. I’ve seen how Ningbo Senjun New Materials Co., Ltd. designs their products to excel in extreme conditions, such as medical ultra-low temperature refrigerators.

How do I choose the right size for my application?

I always recommend consulting experts like Senjun. They offer customizable solutions tailored to specific needs. Their team evaluates factors like space constraints, heat load, and system requirements to ensure the perfect fit.

Are these heat exchangers easy to maintain?

Absolutely. Copper’s resistance to corrosion and aluminum’s protective oxide layer minimize maintenance needs. I’ve noticed that Senjun’s products are designed for durability, reducing the frequency of repairs and ensuring long-term reliability.

What industries benefit most from these heat exchangers?

I’ve seen them used in refrigeration, HVAC, medical cooling, and industrial dehumidification. Ningbo Senjun New Materials Co., Ltd. specializes in creating heat exchangers for refrigerators, freezers, wine cabinets, and more, making them versatile for various industries.