What are the key differences between copper tube aluminum fin heat exchangers and stainless steel heat exchangers?

When it comes to heat exchangers, the choice of material plays a crucial role in performance. Copper tube aluminum fin heat exchangers excel in thermal efficiency due to copper’s exceptional conductivity, which is nearly 20 times greater than stainless steel. This makes them ideal for applications requiring rapid heating or cooling, such as air conditioners and refrigerators. On the other hand, stainless steel heat exchangers stand out for their durability and resistance to corrosion, making them suitable for harsh environments like desalination plants or food processing facilities.

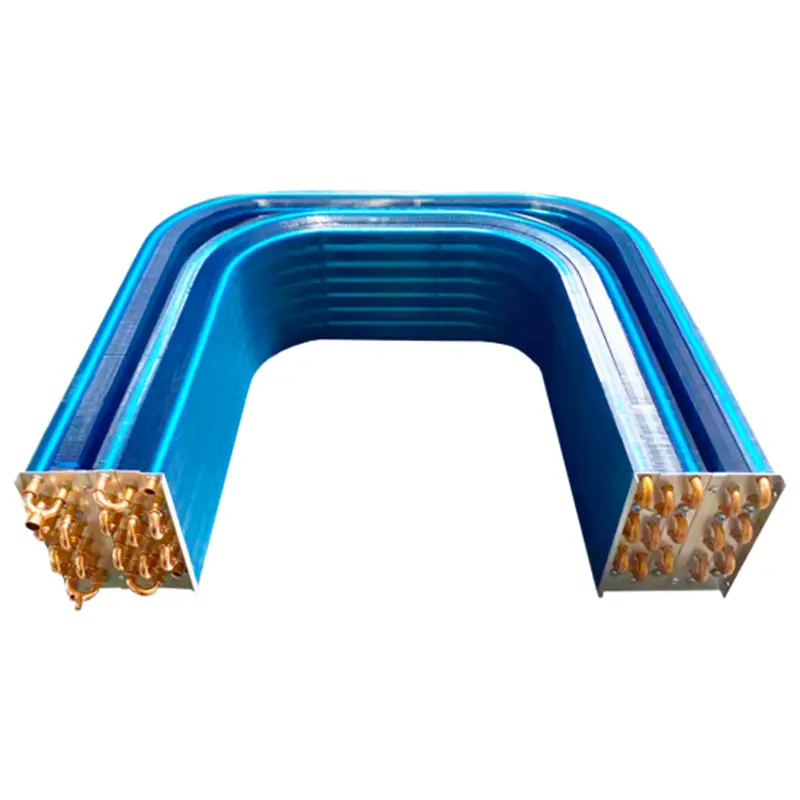

At senjun, we specialize in manufacturing high-quality Copper Fin Heat Exchanger products for various applications, including refrigerators, freezers, and medical ultra-low temperature refrigerators. Our expertise ensures reliable performance tailored to your needs.

Key Takeaways

- Copper tube aluminum fin heat exchangers work well for quick heating or cooling.

- Stainless steel heat exchangers are strong and resist rust, great for tough environments.

- Copper moves heat faster, while stainless steel works steadily for heating or cooling.

- Think about upkeep: copper might need more care in harsh places, but stainless steel usually needs less.

- Pick based on use: choose copper for cheaper, efficient jobs, and stainless steel for lasting strength in hard conditions.

Thermal Efficiency

Heat Transfer Capabilities

Copper's superior thermal conductivity and faster heat transfer

When it comes to heat transfer, copper stands out as a top performer. Its thermal conductivity reaches up to 401 watts per meter per Kelvin, making it one of the most efficient materials for transferring heat. In comparison, stainless steel offers a much lower thermal conductivity, typically below 20 watts per meter per Kelvin. This means copper transfers heat nearly 20 times faster than stainless steel. For applications requiring rapid heating or cooling, such as air conditioning systems or refrigerators, copper tube aluminum fin heat exchangers provide unmatched efficiency.

At senjun, we focus on leveraging copper's exceptional properties to create high-performance heat exchangers. This ensures that our products deliver reliable and efficient thermal performance for various applications, including medical ultra-low temperature refrigerators and dehumidifiers.

Stainless steel's lower thermal conductivity but consistent performance

Although stainless steel lacks copper's high thermal conductivity, it compensates with consistent and stable performance. Its lower heat transfer rate makes it suitable for applications where gradual and controlled heating or cooling is required. Stainless steel heat exchangers excel in environments where durability and resistance to corrosion are more critical than rapid heat transfer.

Design and Material Impact

Role of aluminum fins in copper tube aluminum fin heat exchangers

The design of aluminum fins plays a crucial role in enhancing the efficiency of copper tube aluminum fin heat exchangers. Aluminum fins surround the copper tubes, significantly increasing the heat exchange surface area. Aluminum's excellent heat transfer properties allow it to efficiently dissipate thermal energy from the copper tubes to the surrounding air. The fins are strategically shaped and positioned to promote airflow, ensuring optimal heat dissipation and minimizing energy loss. This combination of copper and aluminum creates a lightweight, cost-effective, and highly efficient system.

Stainless steel's uniform construction and its effect on heat distribution

Stainless steel heat exchangers rely on their uniform construction to ensure even heat distribution. The material's consistent structure allows for steady thermal performance, making it ideal for applications where precision and reliability are essential. While stainless steel may not match the rapid heat transfer of copper, its uniformity ensures long-term efficiency and durability.

At senjun, we understand the importance of material design in heat exchangers. Our copper tube aluminum fin heat exchangers are crafted to maximize thermal efficiency while maintaining reliability across various applications.

Durability

Corrosion Resistance

Copper's susceptibility to certain types of corrosion

Copper performs well in many environments, but it is not immune to corrosion. I have observed that certain conditions, like coastal or marine environments, can accelerate corrosion in copper tube aluminum fin heat exchangers. For example:

- Pitting corrosion occurs due to chloride or fluoride ions, which are common in salty air near oceans.

- Formicary corrosion results from organic acids, often invisible until leaks develop.

- Galvanic corrosion happens when copper and aluminum come into contact with an electrolyte, such as moisture, which is typical in HVAC systems.

These factors make copper less suitable for highly corrosive environments. However, proper coatings and maintenance can mitigate these risks.

Stainless steel's high resistance to rust and chemical corrosion

Stainless steel, on the other hand, offers exceptional corrosion resistance. Its ability to resist rust and chemical damage makes it ideal for harsh conditions. I’ve learned that different grades of stainless steel, like 316L, provide varying levels of protection. For example:

- 316L stainless steel resists corrosion better than 304L, especially in marine settings.

- Duplex stainless steels, such as 2205, offer even higher resistance.

- For extreme environments, materials like titanium or Hastelloy alloys are recommended.

This versatility ensures stainless steel heat exchangers last longer with minimal degradation.

Mechanical Strength

Copper's softness and vulnerability to physical damage

Copper is a softer material, which makes it more prone to dents and damage under physical stress. While this softness allows for easier shaping and installation, it also means copper tube aluminum fin heat exchangers require careful handling. In high-stress environments, copper may not hold up as well as other materials.

Stainless steel's superior mechanical strength in high-stress environments

Stainless steel stands out for its strength and durability. It can withstand high pressure and temperature without losing its structural integrity. Based on comparisons, stainless steel has higher tensile strength and hardness than copper.

| Material | Tensile Strength | Hardness |

|---|---|---|

| Copper | Lower | Softer |

| Stainless Steel | Higher | Harder |

This makes stainless steel the preferred choice for demanding applications, such as industrial heat exchangers. Its robust nature reduces the risk of damage, ensuring reliable performance over time.

At senjun, we prioritize durability in our copper tube aluminum fin heat exchangers. While copper offers excellent thermal efficiency, we ensure our products are designed to withstand various operational challenges, providing reliable performance for applications like refrigerators, freezers, and dehumidifiers.

Cost Analysis

Upfront Costs

Lower material and manufacturing costs of copper and aluminum

Copper tube aluminum fin heat exchangers typically have lower upfront costs due to the affordability of aluminum. While copper is one of the more expensive materials, aluminum helps offset this cost, making the combination more economical. Stainless steel, on the other hand, is generally less expensive than copper but requires more complex manufacturing processes, which can increase its initial price.

- Material Costs:

- Copper is the most expensive material for heat exchangers.

- Aluminum is less expensive than copper but more costly than stainless steel.

- Stainless steel is the least expensive material among the three.

At senjun, we optimize the use of copper and aluminum to create cost-effective heat exchangers without compromising on performance. This makes our products an excellent choice for applications like refrigerators and dehumidifiers.

Higher initial cost of stainless steel due to material properties

Stainless steel heat exchangers often come with a higher upfront cost. This is due to the material's durability and resistance to corrosion, which require advanced manufacturing techniques. However, this initial investment can pay off in the long run, especially in demanding environments where durability is critical.

Long-Term Costs

Maintenance and repair costs for copper tube aluminum fin heat exchangers

Over time, copper tube aluminum fin heat exchangers may require more frequent maintenance. Copper's susceptibility to oxidation and corrosion, particularly in humid or salty environments, can lead to additional upkeep. Aluminum fins may also need protection in corrosive settings, further increasing maintenance costs.

- Maintenance Needs:

- Copper may demand more frequent upkeep in environments prone to corrosion.

- Aluminum fins require additional care in harsh conditions.

Despite these considerations, senjun ensures that our copper tube aluminum fin heat exchangers are designed for reliability and ease of maintenance, making them a practical choice for many applications.

Lower maintenance costs but higher initial investment for stainless steel

Stainless steel heat exchangers require less maintenance over their lifespan. Their resistance to corrosion and wear significantly reduces the need for repairs or replacements. While the initial cost is higher, the long-term savings on maintenance make stainless steel a cost-effective option for industries requiring durability.

| Material | Initial Cost | Maintenance Needs | Thermal Efficiency |

|---|---|---|---|

| Copper | Higher | Moderate | Superior |

| Stainless Steel | Lower | Lower | Moderate |

For long-term projects, stainless steel heat exchangers offer excellent value. However, for cost-sensitive applications, senjun's copper tube aluminum fin heat exchangers provide an efficient and affordable solution.

Maintenance Requirements

Ease of Maintenance

Cleaning and servicing copper tube aluminum fin heat exchangers

I’ve found that maintaining copper tube aluminum fin heat exchangers is relatively straightforward. The smooth surfaces of copper tubes make cleaning efficient, allowing contaminants to be removed easily. Regular cleaning of the aluminum fins is essential to prevent airflow obstruction, which can reduce thermal efficiency. However, environmental factors like humidity or salty air can accelerate corrosion in aluminum fins. Applying protective coatings to copper coils in aggressive environments can help mitigate this issue.

At senjun, we design our copper tube aluminum fin heat exchangers with ease of maintenance in mind. This ensures that users can clean and service them without hassle, prolonging their lifespan and maintaining optimal performance.

Maintenance simplicity of stainless steel heat exchangers

Stainless steel heat exchangers require less frequent maintenance due to their high resistance to corrosion and wear. This durability makes them ideal for environments where upkeep needs to be minimal. Unlike copper-based designs, stainless steel does not need protective coatings or frequent cleaning to maintain its integrity. For most applications, occasional inspections and basic cleaning are sufficient to keep these heat exchangers running efficiently.

| Heat Exchanger Type | Maintenance Procedures |

|---|---|

| Copper Tubes with Aluminum Fins | Easy to clean; smooth surfaces allow for efficient removal of contaminants; regular cleaning prolongs lifespan. |

| Stainless Steel Heat Exchangers | Requires less maintenance due to corrosion resistance; less frequent upkeep needed compared to copper. |

Common Issues

Potential for fin damage in copper tube aluminum fin designs

One common challenge I’ve observed with copper tube aluminum fin heat exchangers is the potential for fin damage. Aluminum fins, while excellent for heat dissipation, are relatively soft and can bend or deform under physical stress. This can obstruct airflow and reduce efficiency. Corrosion is another concern, especially in environments with high levels of contaminants. Regular inspections and careful handling during maintenance can help address these issues.

Rare but possible scaling or fouling in stainless steel heat exchangers

Although stainless steel heat exchangers are highly durable, they are not entirely immune to scaling or fouling. Scaling, caused by minerals like calcium carbonate or silicates, can accumulate on the surface over time. This increases thermal resistance and reduces efficiency. To prevent this, I recommend pretreating water with demineralizers or water softeners and implementing a regular water treatment program. Biological growth, such as bacteria or algae, can also occur but is less common.

- Pretreat boiler make-up water using demineralizers and water softeners.

- Establish an ongoing water treatment program with regular maintenance.

- Reduce mineral content in water sources through chemical softening and membrane separation.

By addressing these potential issues proactively, stainless steel heat exchangers can maintain their efficiency and reliability over the long term.

At senjun, we understand the importance of durability and ease of maintenance. Our copper tube aluminum fin heat exchangers are designed to minimize common issues, ensuring reliable performance for applications like refrigerators, freezers, and dehumidifiers.

Use Cases

When to Choose Copper Tube Aluminum Fin Heat Exchangers

Applications requiring high thermal efficiency and lightweight design

I often recommend copper tube aluminum fin heat exchangers for applications where high thermal efficiency and lightweight construction are essential. Copper’s superior thermal conductivity ensures rapid heat transfer, making these heat exchangers ideal for HVAC systems, refrigeration units, and electronic cooling systems. Aluminum fins enhance the heat exchange surface area while keeping the overall weight low. This combination works well in residential air conditioning units and vehicular radiators, where efficiency and portability are critical.

For example, in large commercial HVAC systems, the lightweight design reduces installation challenges while maintaining excellent performance. At senjun, we design these heat exchangers to meet the demands of industries like refrigeration and dehumidification, ensuring reliable and efficient operation.

Cost-sensitive projects with moderate environmental demands

Copper tube aluminum fin heat exchangers also shine in cost-sensitive projects. While copper is a premium material, the use of aluminum helps balance the overall cost, making these systems more affordable than stainless steel alternatives. However, I always consider the environmental conditions. These heat exchangers perform best in moderate environments where corrosion risks are minimal. For instance, residential heating and cooling systems benefit from their cost-effectiveness and efficiency without requiring the added durability of stainless steel.

When to Choose Stainless Steel Heat Exchangers

Harsh environments with high corrosion risks

In harsh environments, I always turn to stainless steel heat exchangers. Their exceptional resistance to corrosion makes them the preferred choice for industries like chemical processing, desalination plants, and marine services. Stainless steel maintains its integrity even when exposed to saltwater, harsh chemicals, or extreme temperatures. This durability ensures a longer lifespan and reduces the need for frequent replacements.

For example, in desalination plants, stainless steel heat exchangers handle the corrosive effects of saltwater while maintaining consistent performance. Their ability to resist scaling and fouling further enhances their reliability in aggressive environments.

Long-term projects where durability outweighs initial cost

For long-term projects, stainless steel heat exchangers offer unmatched value. Their strength and durability allow them to withstand high pressures and temperatures without compromising performance. Although the initial investment is higher, the reduced maintenance costs and extended lifespan make them a cost-effective solution over time.

Industries like food processing and power generation benefit from this durability. Stainless steel’s ability to handle both hot and cold fluids efficiently aligns with sustainability goals by reducing energy usage and carbon footprints. At senjun, we understand the importance of durability and efficiency, which is why we focus on creating reliable solutions for demanding applications.

About senjun

Company Overview

Introduction to Ningbo Senjun New Materials Co., Ltd.

Ningbo Senjun New Materials Co., Ltd., founded in 2010, has become a prominent name in the cooling industry. Over the years, I’ve seen how Senjun has focused on the research, development, and production of wire tube condensers and copper-aluminum fin heat exchangers. These products serve a wide range of applications, including refrigerators, freezers, and medical ultra-low temperature refrigerators. This versatility showcases Senjun’s expertise and commitment to delivering high-quality solutions tailored to diverse needs.

Senjun’s dedication to innovation sets it apart. The company employs advanced materials like high-quality copper alloys and optimized aluminum fins to enhance durability and heat transfer. Precision laser welding techniques improve product longevity while reducing energy consumption. I also admire their eco-friendly designs, which minimize refrigerant usage and explore natural refrigerants, aligning with global sustainability goals.

Expertise in copper aluminum fin heat exchangers and wire tube condensers

Senjun’s copper aluminum fin heat exchangers stand out for their superior design and performance. The use of hydroponic aluminum fins and flat fin types ensures efficient heat dissipation. With customizable fin spacing ranging from 1.2 to 3.5mm and precise hole pitches, these heat exchangers meet the demands of various industries. Compared to competitors, Senjun’s products offer unmatched reliability and efficiency.

| Feature | Senjun's Copper Aluminum Fin Heat Exchanger | Competitors' Heat Exchangers |

|---|---|---|

| Materials | Copper tube aluminum fin, galvanized plate | Varies |

| Aluminum fin | Hydroponic fin | Varies |

| Fin type | Flat fin | Varies |

| Fin space | 1.2—3.5mm | Varies |

| Pitch of holes/rows | 19.0512.7mm; 25.522mm; 25*21.65mm | Varies |

Product Applications

Use in refrigerators, freezers, and medical ultra-low temperature refrigerators

Senjun’s heat exchangers play a vital role in refrigeration systems. I’ve noticed their widespread use in refrigerators and freezers, where they ensure efficient cooling and energy savings. In medical ultra-low temperature refrigerators, these heat exchangers maintain precise temperature control, which is critical for preserving sensitive materials like vaccines and biological samples.

Applications in ice makers, dehumidifiers, and display cabinets

Beyond refrigeration, Senjun’s products excel in other cooling applications. Ice makers rely on their heat exchangers for rapid and consistent ice production. Dehumidifiers benefit from their ability to efficiently remove moisture from the air, improving indoor air quality. Display cabinets, often used in retail and food industries, depend on Senjun’s solutions to maintain optimal temperatures while showcasing products effectively.

Senjun’s commitment to energy efficiency further enhances these applications. Their wire tube condensers deliver high performance with lower energy consumption. Compact and lightweight designs simplify installation, while innovations like natural refrigerants reduce environmental impact. These features make Senjun a trusted partner in the cooling industry.

Choosing between copper tube aluminum fin heat exchangers and stainless steel heat exchangers depends on your specific needs. Copper tube aluminum fin heat exchangers excel in thermal efficiency and lightweight design, making them ideal for applications requiring rapid heat transfer. However, they may need more maintenance in corrosive environments. Stainless steel heat exchangers, with their unmatched durability and corrosion resistance, are better suited for demanding conditions but come with a higher upfront cost.

Here’s a quick comparison to help you decide:

| Material | Cost | Performance | Advantages | Disadvantages |

|---|---|---|---|---|

| Copper | Higher | High thermal efficiency | Excellent thermal conductivity | Susceptible to galvanic corrosion |

| Aluminum | Moderate | Good thermal efficiency | Cost-effective | Lower durability compared to stainless steel |

| Stainless Steel | Lower | Lower thermal conductivity | Corrosion resistant, strong | Heavier, lower heat transfer efficiency |

Environmental and operational factors also play a role in material selection:

| Factor | Description |

|---|---|

| Thermal Conductivity | Higher thermal conductivity improves heat transfer efficiency. Copper and aluminum are preferred. |

| Corrosion Resistance | Materials must resist corrosion from fluids; stainless steel is a common choice. |

| Cost Considerations | Balancing performance and budget is crucial; copper and aluminum are cost-effective options. |

| Environmental Considerations | Sustainability and recyclability are increasingly important; aluminum is a recyclable option. |

At senjun, we specialize in manufacturing high-quality copper tube aluminum fin heat exchangers tailored to diverse applications. From refrigerators to medical ultra-low temperature refrigerators, our products deliver reliable performance and efficiency. Trust senjun for innovative solutions that meet your cooling needs.

FAQ

What are the main advantages of copper tube aluminum fin heat exchangers?

Copper tube aluminum fin heat exchangers excel in thermal efficiency and lightweight design. Copper’s high conductivity ensures rapid heat transfer, while aluminum fins enhance surface area for better performance. At senjun, we design these exchangers for applications like refrigerators and dehumidifiers, ensuring reliable and efficient cooling.

Why is stainless steel preferred in harsh environments?

Stainless steel resists corrosion and withstands extreme conditions. Its durability makes it ideal for industries like chemical processing or marine applications. I’ve seen how its strength ensures long-term reliability, even in demanding environments. For projects requiring longevity, stainless steel offers unmatched value.

How do I choose between copper and stainless steel heat exchangers?

The choice depends on your application. Copper tube aluminum fin exchangers suit cost-sensitive projects needing high thermal efficiency. Stainless steel works best in corrosive or high-stress environments. At senjun, we help customers select the right solution for their specific needs.

Are senjun’s heat exchangers customizable?

Yes, senjun offers customizable options for copper aluminum fin heat exchangers. We adjust fin spacing, hole pitches, and materials to meet diverse industry requirements. This flexibility ensures our products perform optimally in applications like medical refrigerators, ice makers, and display cabinets.

What industries benefit most from senjun’s products?

Senjun’s heat exchangers serve industries like refrigeration, medical equipment, and food storage. Our products are used in refrigerators, freezers, dehumidifiers, and more. I’ve seen how our innovative designs enhance energy efficiency and reliability across various applications.