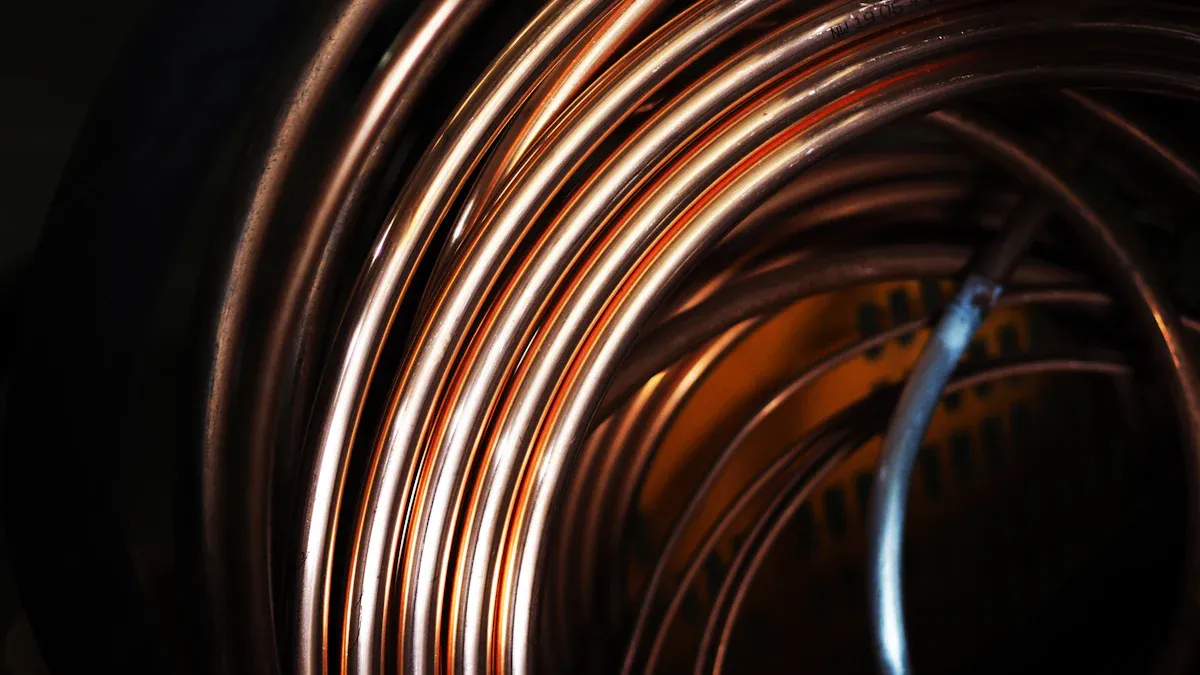

What Are the Advantages of Using Copper Tube Copper Fin Heat Exchangers in High-Performance Refrigeration?

Copper tube copper fin heat exchangers deliver unmatched performance in high-performance refrigeration systems. Their superior thermal conductivity, approximately 400 W/m·K, ensures efficient heat transfer, outperforming materials like aluminum and stainless steel. Industries such as HVAC, food storage, and medical refrigeration rely on these systems for energy efficiency and reliability.

Ningbo Senjun New Materials Co., Ltd. (senjun) leads in producing copper aluminum fin heat exchangers and wire tube condensers. Their solutions power refrigerators, freezers, medical ultra-low temperature refrigerators, and more. By choosing senjun, businesses gain access to innovative, durable, and eco-friendly refrigeration technologies.

Key Takeaways

- Copper tube copper fin heat exchangers move heat very well. This helps cool things faster in refrigeration systems.

- Using copper heat exchangers saves energy and lowers repair costs. This makes them a smart and affordable choice for businesses.

- Copper does not rust easily and can be recycled. This makes it last long and good for the environment.

Superior Thermal Conductivity and Efficiency

Copper’s Exceptional Heat Transfer Properties

When it comes to heat transfer, copper stands out as one of the most efficient materials. Its thermal conductivity reaches approximately 400 W/m·K, far surpassing other metals like aluminum (237 W/m·K) and stainless steel (16 W/m·K). This exceptional property allows copper to transfer heat nearly 20 times more effectively than stainless steel. In refrigeration systems, this means faster and more reliable cooling.

Copper's high thermal conductivity ensures that heat exchangers, such as copper tube copper fin heat exchangers, perform at their peak. These systems can quickly remove heat from refrigeration units, maintaining optimal temperatures for food storage, medical equipment, and more. At senjun, we specialize in crafting copper aluminum fin heat exchangers that leverage copper's superior heat transfer capabilities. This ensures our products deliver unmatched efficiency and reliability.

Enhanced System Performance and Energy Savings

The efficiency of copper tube copper fin heat exchangers directly impacts the overall performance of refrigeration systems. Copper's ability to transfer heat efficiently reduces the workload on compressors, leading to lower energy consumption. For instance, using smaller diameter copper tubes not only enhances heat transfer but also reduces the refrigerant charge required. This results in cost savings and a more eco-friendly operation.

At senjun, we understand the importance of energy-efficient solutions. Our heat exchangers are designed to optimize system performance while minimizing environmental impact. By choosing copper-based systems, businesses can achieve significant energy savings and contribute to sustainable practices.

Corrosion Resistance and Longevity

Copper’s Natural Resistance to Environmental Degradation

Copper stands out for its remarkable ability to resist corrosion, even in challenging environments. Unlike other materials, copper develops a natural patina over time. This protective layer shields it from further damage, making it ideal for long-term use in humid or salty conditions. For example, aluminum, while resistant to some forms of corrosion, is more vulnerable when exposed to dissimilar metals. This can lead to galvanic corrosion, which compromises durability.

Copper Tube Copper Fin Heat Exchangers eliminate this issue by using copper exclusively for both tubes and fins. This uniformity prevents galvanic reactions and ensures the system remains intact over time. At senjun, we design our heat exchangers to leverage copper's natural resistance, ensuring they perform reliably in harsh environments. Whether it’s a medical ultra-low temperature refrigerator or a dehumidifier, our products maintain their integrity and efficiency for years.

Reduced Maintenance Costs and Extended Lifespan

Copper-based heat exchangers may have a higher upfront cost, but their long-term benefits outweigh the initial investment. Their superior corrosion resistance reduces the need for frequent repairs or replacements. For instance, aluminum heat exchangers, while cheaper, often deteriorate faster in humid environments. This leads to higher maintenance costs and shorter lifespans.

In contrast, copper systems, like those produced by senjun, offer durability and reliability. Businesses save money over time by avoiding frequent replacements. Additionally, copper's ability to maintain its structural integrity ensures consistent performance, even in demanding applications like freezers or ice makers. By choosing copper-based solutions, companies can achieve both cost efficiency and long-term sustainability.

Design Flexibility and Performance

Versatility in Customizing Heat Exchanger Designs

Copper offers unmatched versatility when designing heat exchangers. Its malleability allows it to be shaped into intricate forms, meeting the unique needs of various industries. For example:

- Copper can be stretched into thin wires without breaking, enabling the creation of complex designs.

- Its atomic structure adapts well to tight or irregular spaces, making it ideal for custom applications.

At senjun, we leverage copper's flexibility to produce tailored solutions for diverse industries. Our copper aluminum fin heat exchangers are used in refrigerators, freezers, and medical ultra-low temperature refrigerators. We also design hybrid systems for ice makers, dehumidifiers, and display cabinets. These customized designs ensure optimal performance, no matter the application.

Compact and Lightweight Solutions for High-Performance Systems

Copper's superior thermal conductivity allows us to create smaller, more efficient heat exchangers. This reduces the overall size and weight of the system without compromising performance. For instance:

| Benefit | Description |

|---|---|

| Thermal Conductivity | Copper transfers heat rapidly, ensuring efficient cooling. |

| Energy Consumption | Faster heat transfer reduces energy use, enhancing system efficiency. |

| Compatibility with Refrigerants | Smaller diameter coils handle higher pressures, supporting eco-friendly refrigerants. |

Compared to aluminum, copper's higher tensile strength ensures durability under mechanical stress. This makes it a reliable choice for demanding applications like medical refrigeration and industrial cooling. At senjun, we prioritize compact and lightweight designs to meet the needs of high-performance systems. Our solutions not only save space but also improve energy efficiency, aligning with modern sustainability goals.

Environmental Sustainability

Recyclability of Copper Materials

Copper is one of the most recyclable materials on the planet, and its use in refrigeration systems highlights its environmental benefits. Recycling copper requires only 15% of the energy needed to mine and refine new copper. This energy efficiency directly reduces greenhouse gas emissions, helping to combat climate change. Additionally, recycling keeps valuable materials out of landfills, minimizing waste and promoting a sustainable supply chain.

At senjun, we prioritize sustainability by designing copper aluminum fin heat exchangers that leverage copper's recyclability. By choosing our products, businesses not only benefit from high-performance refrigeration but also contribute to a greener planet.

♻️ Did you know? Recycling copper not only saves energy but also preserves natural resources, ensuring a more sustainable future for generations to come.

Contribution to Eco-Friendly Refrigeration Practices

Copper-based heat exchangers align perfectly with global eco-friendly refrigeration initiatives. Their design supports the use of low Global Warming Potential (GWP) refrigerants, which significantly reduce greenhouse gas emissions. Here’s how copper contributes to sustainable refrigeration:

- Copper's thermal conductivity enhances energy efficiency, reducing reliance on carbon-intensive methods.

- Small-diameter copper tubes lower refrigerant charge requirements, minimizing environmental impact.

- Compatibility with natural refrigerants like propane and carbon dioxide promotes sustainability in HVAC/R applications.

| Evidence | Description |

|---|---|

| Reduced Refrigerant Charge | Using 4mm copper tubes decreases the heat exchanger's volume and cost while lowering the refrigerant charge. |

| Compact Design | Smaller-diameter copper tubes simplify storage and transport, reducing overall system charge. |

| Support for Natural Refrigerants | Copper facilitates the adoption of low GWP refrigerants, aligning with eco-friendly practices. |

At senjun, we integrate these principles into our copper aluminum fin heat exchangers, ensuring they meet modern sustainability standards. Whether for refrigerators, freezers, or medical ultra-low temperature refrigerators, our products deliver both performance and environmental benefits.

Copper Tube Copper Fin Heat Exchangers excel in thermal efficiency, durability, and sustainability, making them indispensable for high-performance refrigeration. Businesses benefit from energy savings and reduced maintenance costs. At senjun, we combine copper's conductivity with innovative designs, ensuring reliable solutions for refrigerators, freezers, and medical ultra-low temperature systems. Choose senjun for superior performance and eco-friendly refrigeration.

FAQ

What makes copper tube copper fin heat exchangers better than aluminum ones?

Copper offers superior thermal conductivity, corrosion resistance, and durability. At senjun, we design copper aluminum fin heat exchangers to maximize these benefits for high-performance refrigeration systems.

Are copper-based heat exchangers environmentally friendly?

Yes! Copper is 100% recyclable and supports eco-friendly refrigerants. At senjun, we prioritize sustainability by crafting products that align with modern environmental standards.

Can senjun customize heat exchangers for specific applications?

Absolutely! Senjun specializes in designing tailored solutions for refrigerators, freezers, medical ultra-low temperature refrigerators, and more. Our expertise ensures optimal performance for diverse industry needs.