Top 5 Wire Tube Condenser Manufacturers to Watch in 2025

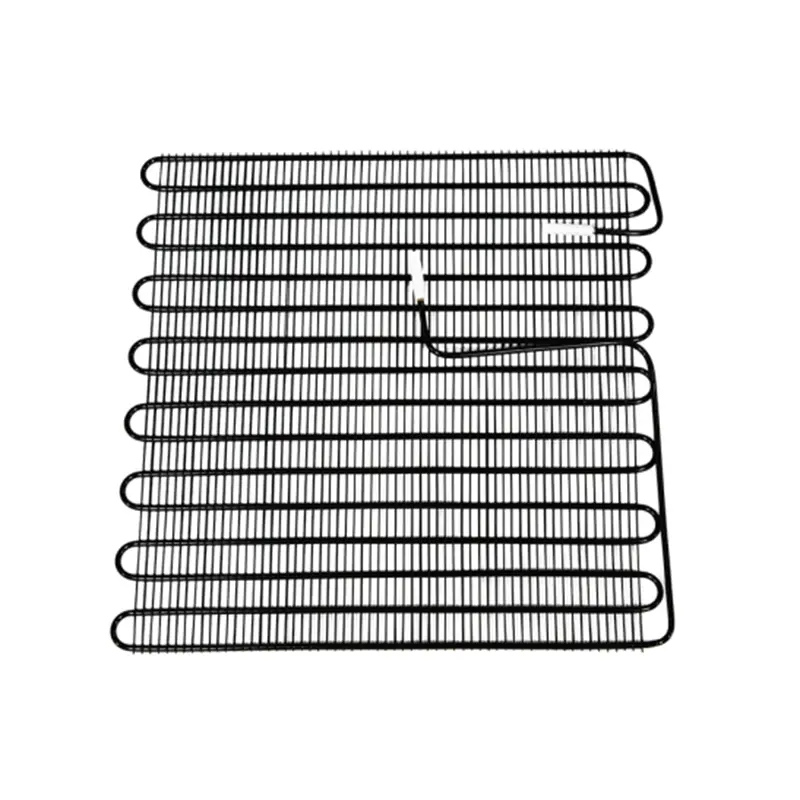

Wire tube condensers play a vital role in refrigeration and cooling systems. These components use tubes and wire fins to transfer heat efficiently. The refrigerant inside changes phases, releasing heat absorbed by the air over the fins. This process ensures optimal cooling performance.

The global demand for these systems continues to rise. In 2023, the wire tube condenser market was valued at $3.5 billion. By 2032, it is expected to reach $5.7 billion, with a CAGR of 6.2%. This growth stems from the need for efficient cooling in residential, commercial, and industrial applications. Identifying top manufacturers helps businesses and consumers choose reliable and innovative solutions.

Key Takeaways

- Wire tube condensers help cool homes and factories efficiently.

- The market for these condensers may grow from $3.5 billion in 2023 to $5.7 billion by 2032 because people want energy-saving products.

- Saving energy is important, so companies make condensers that use less power and follow new rules.

- New technology, like smart systems and better materials, makes these condensers work better and last longer.

- Being eco-friendly matters; companies use green designs and natural coolants to protect the planet.

- Asia Pacific is the biggest market due to growing cities and higher incomes, but North America and Europe also focus on new ideas and eco-friendly solutions.

- Leading companies like Jinan Bestar and Breeze Frost Industries work hard on quality, new ideas, and keeping customers happy.

- When picking a company, look at product quality, new technology, eco-friendly efforts, and customer service.

Industry Trends Shaping the Wire Tube Condenser Market in 2025

Increasing Demand for Energy Efficiency

Energy efficiency has become a top priority in the cooling industry. Rising global temperatures and rapid urbanization have increased the demand for cooling systems that consume less energy. Many governments now enforce stricter regulations to promote energy-efficient technologies and reduce greenhouse gas emissions. This shift has encouraged manufacturers to innovate and create wire tube condensers that deliver better performance with lower energy consumption.

Emerging markets in regions like Asia-Pacific, Latin America, and Africa are also driving this trend. These areas experience growing urban populations and rising incomes, leading to higher demand for efficient cooling solutions. Businesses and consumers alike seek products that not only save energy but also reduce utility costs. Wire tube condensers, known for their effective heat transfer capabilities, play a crucial role in meeting these needs.

Advancements in Manufacturing Technology

Manufacturing technology continues to evolve, bringing significant improvements to wire tube condenser production. Smart technology integration, such as IoT, allows real-time monitoring and control of cooling systems. This innovation enhances energy efficiency and system reliability. For example, IoT-enabled condensers can adjust performance based on environmental conditions, ensuring optimal cooling at all times.

Sustainable materials are another key advancement. Manufacturers now use eco-friendly materials like new copper alloys, which improve corrosion resistance and thermal conductivity. These materials extend the lifespan of condensers while reducing their environmental impact. Advanced techniques like laser welding create durable joints, minimizing leaks and enhancing overall performance.

Additionally, 3D printing and computer-aided design (CAD) have revolutionized production processes. These technologies enable the creation of complex and efficient designs tailored to specific applications. For instance, CAD ensures optimal geometries for maximum heat transfer, while 3D printing allows for rapid prototyping and customization.

Focus on Sustainability and Eco-Friendly Solutions

Sustainability has become a central focus in the wire tube condenser market. Manufacturers are adopting eco-friendly designs to align with global environmental goals. Recent innovations include the use of natural refrigerants, such as hydrocarbons, which have a lower global warming potential compared to traditional refrigerants. These advancements reduce the environmental impact of cooling systems.

Compact and lightweight structures are another trend in sustainable design. These features not only improve energy efficiency but also make condensers easier to install and maintain. Enhanced materials, like aluminum fins with optimized thickness and spacing, further boost heat dissipation and durability.

The industry also emphasizes reducing refrigerant usage. By requiring less refrigerant, modern wire tube condensers contribute to energy savings and environmental protection. These innovations are particularly valuable in applications like cold-chain logistics, where efficient and reliable cooling is essential.

Global Market Expansion and Regional Leaders

The wire tube condenser market is expanding rapidly across the globe. This growth reflects the increasing demand for efficient cooling systems in residential, commercial, and industrial sectors. Each region contributes uniquely to this expansion, driven by its economic conditions, technological advancements, and consumer needs.

Asia Pacific leads the global market. It has the largest share due to its growing urban population and rising disposable incomes. Countries like China and India are investing heavily in infrastructure and industrial development. These factors create a high demand for cooling systems. By 2023, the Asia Pacific market reached $1.5 billion. Experts predict it will grow to $2.8 billion by 2032, with a compound annual growth rate (CAGR) of 7.1%. This region's focus on energy-efficient and sustainable solutions further accelerates its growth.

North America also plays a significant role in the market. The region benefits from advanced manufacturing technologies and strict energy efficiency regulations. In 2023, North America's market size was $1.2 billion. It is expected to grow to $1.8 billion by 2032, with a CAGR of 4.5%. The United States leads this region, driven by its strong industrial base and demand for innovative cooling solutions.

Europe remains a key player, although specific market size data is unavailable. The region emphasizes sustainability and eco-friendly designs. European manufacturers focus on reducing environmental impact by adopting natural refrigerants and lightweight materials. This approach aligns with the region's strict environmental policies and commitment to reducing carbon emissions.

Here is a summary of the market size and growth projections for key regions:

| Region | Market Size (2023) | Projected Size (2032) | CAGR (%) |

|---|---|---|---|

| Asia Pacific | $1.5 billion | $2.8 billion | 7.1 |

| North America | $1.2 billion | $1.8 billion | 4.5 |

| Europe | N/A | N/A | N/A |

The global expansion of the wire tube condenser market highlights the importance of regional leaders. Manufacturers in these regions drive innovation and set industry standards. Their efforts ensure the availability of high-quality, energy-efficient cooling solutions worldwide.

Top 5 Wire Tube Condenser Manufacturers in 2025

Ningbo Senjun New Materials Co., Ltd.

Background and History

Ningbo Senjun New Materials Co., Ltd. was established in 2010 and has since become a prominent player in the cooling industry. The company specializes in the research, development, and production of wire tube condensers and copper-aluminum fin heat exchangers for various applications, including refrigerators, freezers, drinking fountains, display cabinets, wine cabinets, medical ultra-low temperature refrigerators, ice makers, and dehumidifiers. With a commitment to innovation and development, Senjun has built a reputation for reliability and quality in the market.

Key Achievements and Milestones

Senjun has achieved several significant milestones that underscore its leadership in the industry. These accomplishments reflect its dedication to growth, sustainability, and strong customer relationships.

| Achievement | Description |

| Advanced Production Equipment | Investment in state-of-the-art production machinery has enhanced efficiency and product quality. |

| Quality Certifications | Products are certified under ISO9001, ISO/TS16949, ISO14000, and ROHS, ensuring high standards. |

| Strict Quality Management | Implementation of a rigorous quality management system that controls every production stage. |

| Rapid Response to Quality Issues | Quick analysis and resolution of quality issues during product use, leading to continuous improvement. |

| Global Market Reach | Established partnerships with clients worldwide, meeting diverse market demands across five continents. |

Innovations in Wire Tube Condenser Technology

Ningbo Senjun has consistently introduced innovations to enhance the performance and efficiency of its products. The company prioritizes technological advancement in the cooling industry, focusing on eco-friendly practices and advanced manufacturing processes. Key innovations include:

- Advanced Materials: Utilizing high-quality copper alloys and optimized aluminum fins for improved durability and heat transfer.

- Laser Welding Techniques: Implementing precision welding methods that enhance product durability and reduce energy consumption.

- Eco-Friendly Designs: Committing to sustainable practices by reducing refrigerant usage and exploring natural refrigerants.

These innovations ensure that Senjun’s wire tube condensers meet the highest standards of quality and efficiency.

Why They Are a Leader in 2025

Ningbo Senjun stands out as a leader in 2025 due to its unwavering focus on innovation, sustainability, and customer satisfaction. The company's ability to enhance productivity while reducing costs has solidified its position in the market. Its commitment to environmental responsibility and continuous improvement ensures that it remains a top choice for businesses and consumers seeking reliable cooling solutions.

Breeze Frost Industries

Background and History

Breeze Frost Industries, based in the United States, has been a pioneer in the cooling industry. The company started as a small family-owned business and has grown into a global leader. Its dedication to innovation and customer satisfaction has driven its success over the years.

Key Achievements and Milestones

Breeze Frost Industries has achieved remarkable growth through strategic mergers and acquisitions. These activities have expanded its product range and market reach. The company has also received numerous awards for its contributions to energy efficiency and sustainability in the cooling industry.

Innovations in Wire Tube Condenser Technology

Breeze Frost Industries has introduced several groundbreaking innovations. These include improved energy efficiency, which optimizes heat transfer and reduces refrigerant usage. The company has also developed condensers with longer lifespans and quieter operation. Its use of natural refrigerants and efficient designs minimizes environmental impact, aligning with global sustainability goals.

| Innovation | Description |

|---|---|

| Improved Energy Efficiency | Optimizes heat transfer and reduces refrigerant usage, lowering energy consumption. |

| Longer Lifespan | Enhanced materials and processes lead to more durable condensers. |

| Quiet Operation | Innovations in fan design result in quieter operation. |

| Reduced Environmental Impact | Use of natural refrigerants and efficient designs minimizes environmental impact. |

Why They Are a Leader in 2025

Breeze Frost Industries stands out for its commitment to innovation and sustainability. Its focus on creating energy-efficient and eco-friendly products has earned it a loyal customer base. The company's ability to adapt to market trends ensures its continued leadership in the wire tube condenser market.

Shanghai Venttech Refrigeration

Background and History

Shanghai Venttech Refrigeration has been a key player in the cooling industry for many years. Based in China, the company specializes in designing and manufacturing high-quality wire tube condensers. Its dedication to innovation and sustainability has made it a trusted name in the global market.

Key Achievements and Milestones

Shanghai Venttech Refrigeration has achieved significant milestones, including the development of advanced cooling technologies. The company has also expanded its market presence through strategic partnerships and collaborations. Its focus on customer satisfaction has earned it numerous accolades and a strong reputation in the industry.

Innovations in Wire Tube Condenser Technology

Shanghai Venttech Refrigeration leads the way in adopting cutting-edge technologies. The company incorporates nanotechnology to enhance heat transfer and phase change materials for improved thermal performance. It also uses self-cleaning coatings that reduce maintenance needs. These innovations not only improve efficiency but also align with the industry's shift towards sustainability.

Why They Are a Leader in 2025

Shanghai Venttech Refrigeration's commitment to innovation and eco-friendly practices sets it apart. The company actively improves its products and adapts to market trends. This strategic focus allows it to explore new applications and expand its market reach. Its leadership in adopting sustainable solutions ensures its position as a top manufacturer in 2025.

Bundy Refrigeration

Background and History

Bundy Refrigeration has a long-standing history in the cooling industry. The company began as a small-scale manufacturer and has grown into a global leader in wire tube condenser production. Over the years, Bundy has built a reputation for reliability and innovation. Its focus on improving operational efficiency and customer satisfaction has made it a trusted name in the market.

Key Achievements and Milestones

Bundy Refrigeration has achieved several milestones that demonstrate its leadership in the industry. These accomplishments highlight its commitment to growth, sustainability, and customer relationships.

| Achievement | Description |

|---|---|

| Cash Management Overhaul | Complete overhaul of cash management to build confidence in the management team and improve communication with customers. |

| Productivity Improvement | Investment in new plant machinery has improved productivity and reduced energy usage. |

| Profit Return | Since 2018, the company has returned to profit and retained key management staff. |

| Corporate Overhead Reduction | Achieved a 25% reduction in corporate overheads. |

| Supply Chain Relationships | Improved relationships with supply chains and customers. |

| Sustainability Initiatives | Initiated a program to reduce environmental impact and comply with future climate change regulations. |

| Market Expansion | Plans to expand into emerging markets and promote continuous improvement. |

These achievements reflect Bundy’s ability to adapt to market demands and maintain its competitive edge.

Innovations in Wire Tube Condenser Technology

Bundy Refrigeration has consistently introduced innovations to enhance the performance and efficiency of its products. The company has invested in advanced manufacturing processes, such as laser welding, to improve product durability and reduce energy consumption. It has also adopted sustainable practices, including the use of eco-friendly materials and designs that minimize environmental impact. These innovations ensure that Bundy’s wire tube condensers meet the highest standards of quality and efficiency.

Why They Are a Leader in 2025

Bundy Refrigeration stands out as a leader in 2025 due to its focus on innovation, sustainability, and customer satisfaction. The company’s ability to improve productivity while reducing costs has strengthened its position in the market. Its commitment to environmental responsibility and continuous improvement ensures that it remains a top choice for businesses and consumers seeking reliable cooling solutions.

Refworld

Background and History

Refworld has established itself as a prominent player in the wire tube condenser market. The company specializes in designing and manufacturing high-performance cooling solutions for various applications. Its dedication to research and development has enabled it to stay ahead of industry trends and deliver cutting-edge products.

Key Achievements and Milestones

Refworld has achieved significant milestones that underscore its leadership in the industry. The company has expanded its global presence and developed a loyal customer base through its commitment to quality and innovation. Its focus on sustainability and energy efficiency has earned it recognition as a forward-thinking manufacturer.

Innovations in Wire Tube Condenser Technology

Refworld has introduced several groundbreaking innovations in wire tube condenser technology:

- Enhanced Materials: The use of new copper alloys and optimized aluminum fins improves durability and heat transfer.

- Improved Manufacturing Processes: Techniques like laser welding and CAD enhance precision and efficiency.

- Eco-Friendly Designs: Reduced refrigerant usage and exploration of natural refrigerants align with sustainability goals.

- Smart Condensers: IoT integration and adaptive control features enhance energy efficiency and monitoring.

These advancements demonstrate Refworld’s commitment to creating products that meet the evolving needs of the market while prioritizing environmental responsibility.

Why They Are a Leader in 2025

Refworld’s focus on innovation and sustainability makes it a leader in 2025. The company’s ability to integrate smart technologies and eco-friendly designs into its products sets it apart from competitors. Its dedication to improving product performance and reducing environmental impact ensures its continued success in the wire tube condenser market.

Factors to Consider When Evaluating Wire Tube Condenser Manufacturers

Product Quality and Reliability

When choosing a wire tube condenser manufacturer, product quality and reliability should be your top priorities. High-quality condensers ensure efficient cooling performance and long-term durability. Reliable products reduce the risk of system failures, which can lead to costly repairs or replacements.

Manufacturers that prioritize quality often use advanced materials like copper alloys and optimized aluminum fins. These materials enhance corrosion resistance and thermal conductivity, improving heat transfer efficiency. Additionally, precise manufacturing techniques, such as laser welding, create durable joints that minimize leaks and extend the lifespan of the condenser.

I recommend looking for manufacturers with a proven track record of delivering consistent quality. Companies that invest in rigorous testing and quality control processes demonstrate their commitment to reliability. This ensures that their products meet industry standards and perform well under various conditions.

Innovation and Technological Advancements

Innovation plays a crucial role in the performance and efficiency of wire tube condensers. Technological advancements have transformed the industry, enabling manufacturers to create more efficient and durable products.

Some key innovations include:

- Improved Energy Efficiency: Advanced designs optimize heat transfer and reduce refrigerant usage, lowering energy consumption.

- Longer Lifespan: Enhanced materials and manufacturing processes increase durability and reduce failure rates.

- Reduced Environmental Impact: The adoption of natural refrigerants and efficient designs minimizes harm to the environment.

- Laser Welding: This technique creates precise and durable joints, reducing the likelihood of leaks.

- Computer-Aided Design (CAD): CAD ensures optimal geometries for maximum heat transfer, enhancing overall performance.

Manufacturers that embrace these technologies can deliver products that meet the evolving needs of the market. I suggest evaluating a company's commitment to research and development, as this often reflects its ability to innovate and stay ahead of industry trends.

Sustainability and Environmental Impact

Sustainability has become a critical factor in evaluating wire tube condenser manufacturers. Companies that adopt eco-friendly practices contribute to environmental preservation while meeting regulatory requirements.

Sustainable manufacturing practices include sourcing recycled metals and using eco-friendly coatings. Advanced machinery and renewable energy sources enhance energy efficiency during production. Manufacturers also conduct life cycle assessments to identify areas for improvement, ensuring their products have minimal environmental impact.

Innovative designs further support sustainability. Compact and modular structures reduce waste and energy consumption. Additionally, the use of natural refrigerants aligns with global efforts to lower greenhouse gas emissions. Manufacturers committed to regulatory compliance demonstrate their dedication to sustainability and environmental responsibility.

I encourage you to choose manufacturers that prioritize these practices. Their efforts not only benefit the environment but also ensure the long-term viability of their products.

Customer Support and After-Sales Service

Customer support and after-sales service play a vital role in choosing a wire tube condenser manufacturer. These services ensure that customers receive assistance whenever they face issues with their products. I believe that a company’s dedication to its customers reflects its overall reliability and professionalism.

Manufacturers offering excellent customer support provide clear communication channels. These include phone lines, email support, and live chat options. Quick response times show that the company values its customers’ time and concerns. For example, if a condenser malfunctions, immediate support can prevent prolonged downtime and costly repairs.

After-sales service is equally important. It includes services like installation guidance, maintenance tips, and warranty coverage. Companies that offer these services help customers maximize the lifespan and efficiency of their products. I recommend looking for manufacturers that provide detailed product manuals and online resources. These tools empower customers to troubleshoot minor issues independently.

Training programs for technicians also enhance after-sales service. Some manufacturers organize workshops to educate technicians about their products. This ensures that repairs and maintenance are performed correctly. Additionally, companies with a global presence often have service centers in multiple regions. This makes it easier for customers to access support, regardless of their location.

In my experience, manufacturers that prioritize customer satisfaction build long-term relationships with their clients. They not only resolve issues but also gather feedback to improve their products. This commitment to continuous improvement benefits both the company and its customers.

Global Reach and Market Presence

A manufacturer’s global reach significantly impacts its competitiveness. Companies with a strong international presence can access emerging markets. This allows them to expand their customer base and increase revenue. For instance, regions like Asia-Pacific and Latin America offer immense growth opportunities due to rising demand for cooling solutions.

Global reach also enables manufacturers to leverage economies of scale. By producing in larger quantities, they can reduce costs and offer competitive pricing. This benefits customers who seek high-quality products at affordable rates. Additionally, collaboration with technology leaders across the globe fosters innovation. Manufacturers can adopt advanced techniques and materials to enhance their products.

However, operating on a global scale comes with challenges. High production costs and supply chain disruptions can affect a company’s market position. Intense competition in international markets often leads to price wars. This can result in lower profit margins for manufacturers. Despite these challenges, companies with robust strategies can maintain their edge.

I recommend choosing manufacturers with a strong market presence. These companies often have partnerships with local distributors, ensuring timely delivery of products. Their ability to adapt to regional demands demonstrates their commitment to customer satisfaction. A global presence also reflects a company’s stability and reliability, making it a trustworthy choice for businesses and consumers alike.

Driven by innovation and sustainable development, the wire tube condenser industry continues to grow. The top five manufacturers - Ningbo Senjun New Materials Co., Ltd., Breeze Frost Industries, Shanghai Venttech Refrigeration, Bundy Refrigeration and Refworld have made outstanding contributions. Each company has excelled in areas such as energy efficiency, advanced manufacturing and environmental solutions.

Staying informed about these leaders helps businesses and consumers make better decisions. I encourage you to explore their offerings for reliable and efficient cooling solutions. Their dedication to innovation ensures they remain at the forefront of the industry.

FAQ

What is a wire tube condenser?

A wire tube condenser is a cooling component used in refrigeration systems. It transfers heat from the refrigerant to the surrounding air. This process ensures efficient cooling for appliances like refrigerators, freezers, and ice makers.

Why are wire tube condensers important?

Wire tube condensers improve cooling efficiency. They help appliances maintain consistent temperatures. This ensures food safety, medical storage reliability, and energy savings for consumers.

How do I choose the right manufacturer?

I recommend evaluating product quality, innovation, and sustainability. Look for manufacturers with a strong reputation, advanced technology, and eco-friendly practices. Customer support and global presence also matter.

Are wire tube condensers eco-friendly?

Yes, many manufacturers now focus on sustainability. They use natural refrigerants, recyclable materials, and energy-efficient designs. These innovations reduce environmental impact and align with global green initiatives.

What industries use wire tube condensers?

Wire tube condensers serve various industries. These include refrigeration, medical storage, food and beverage, and dehumidification. They are essential for appliances like refrigerators, wine cabinets, and display coolers.

How do manufacturers ensure product quality?

Manufacturers use advanced materials like copper alloys and aluminum fins. They also adopt precise techniques like laser welding. Rigorous testing ensures durability, efficiency, and reliability.

What trends are shaping the wire tube condenser market?

Energy efficiency, sustainability, and smart technology integration are key trends. Manufacturers now focus on eco-friendly designs and IoT-enabled systems for better performance and monitoring.

Can wire tube condensers be customized?

Yes, many manufacturers offer customization. They use technologies like CAD and 3D printing to create designs tailored to specific applications. This ensures optimal performance for unique needs.