The Future of Refrigeration: How Wire Tube Condensers and Heat Exchangers Are Shaping Modern Cooling Systems

Refrigeration technology is evolving rapidly, and wire tube condensers and heat exchangers are at the forefront of this transformation. These components significantly improve energy efficiency and reduce environmental impact. For instance, wire tube condensers boast a 50% higher heat transfer coefficient compared to traditional plate condensers, which minimizes energy consumption and enhances system reliability. Their optimized airflow design further boosts heat dissipation, making them a sustainable choice for modern cooling systems.

Companies like Ningbo Senjun New Materials Co., Ltd. play a vital role in this innovation. Senjun specializes in developing wire tube condensers and copper fin heat exchangers for a wide range of applications, including refrigerators, freezers, and medical cooling systems. By focusing on advanced materials and efficient designs, they contribute to a greener and more cost-effective future for refrigeration.

Key Takeaways

- Wire tube condensers save 50% more energy, cutting electricity bills and improving cooling.

- These condensers work with green refrigerants, reducing harm to the environment and following new rules.

- Using better refrigeration tools can save money over time and help the planet.

- Companies like Ningbo Senjun New Materials Co., Ltd. create new ideas for eco-friendly and efficient cooling.

- Smart refrigeration systems track performance live, making them more reliable and cheaper to fix.

Current Challenges in Refrigeration

Energy Efficiency Concerns

Energy efficiency remains one of the biggest challenges in refrigeration today. I’ve noticed that the industry is actively working to address environmental concerns by adopting green innovations. These include eco-friendly refrigerants and energy-efficient system designs. However, transitioning to these systems isn’t always straightforward. For example, CO2 refrigerants, which are more sustainable, operate at high pressures. This requires specialized components and trained technicians for maintenance. These factors increase both installation and maintenance costs, making the shift to energy-efficient systems more complex.

Additionally, adapting to new technologies and refrigerants takes time and resources. Many businesses face hurdles as they phase out traditional refrigerants due to evolving regulations. Despite these challenges, companies like Ningbo Senjun New Materials Co., Ltd. are stepping up. Senjun’s focus on advanced materials and efficient designs helps overcome these barriers, paving the way for more sustainable refrigeration solutions.

Environmental Impact of Traditional Refrigerants

Traditional refrigerants have long been a concern due to their harmful effects on the environment. Substances like chlorofluorocarbons (CFCs) and hydrofluorocarbons (HFCs) contribute significantly to global warming and ozone layer depletion. I’ve seen how regulations worldwide are pushing for the phase-out of these refrigerants. This shift is essential, but it also creates challenges for manufacturers and users who must adapt to new, eco-friendly alternatives.

Wire tube condensers and heat exchangers play a crucial role here. Their compatibility with modern refrigerants reduces the environmental footprint of cooling systems. Companies like Senjun are leading this change by designing components that align with these new standards. Their innovations ensure that refrigeration systems remain efficient while minimizing environmental harm.

Rising Demand for Sustainable Cooling Solutions

The demand for sustainable cooling solutions is growing rapidly. I believe this is driven by several factors. Technology solutions, such as advanced heat exchangers, are making systems more efficient. Service solutions, including maintenance and operational support, ensure these technologies perform optimally. Policy measures, like regulatory incentives, encourage businesses to adopt sustainable practices. Financial solutions, such as funding programs, make these options more accessible.

This rising demand highlights the importance of companies like Senjun. Their expertise in wire tube condensers and copper aluminum fin heat exchangers supports the development of sustainable systems for refrigerators, freezers, and even medical cooling applications. By focusing on innovation and sustainability, they meet the needs of a market that increasingly values eco-friendly solutions.

Wire Tube Condensers: A Game-Changer in Refrigeration

What Are Wire Tube Condensers?

Wire tube condensers are essential components in modern refrigeration systems. They consist of Bundy tubes and steel wires, forming a durable and efficient structure. These condensers excel in transferring heat, making them a reliable choice for various applications. I’ve seen their versatility firsthand, as they perform well in household refrigerators, industrial freezers, and even medical cooling systems. Their open design enhances airflow, which improves cooling efficiency and ensures stable temperatures.

Here’s a quick overview of their unique features and benefits:

| Feature | Benefit |

|---|---|

| High heat transfer efficiency | 50% higher heat transfer coefficient compared to plate condensers. |

| Durability | Construction with Bundy tubes and steel wires ensures long-lasting performance. |

| Cost-effectiveness | Low manufacturing cost while optimizing heat transfer reduces electricity bills. |

| Versatility | Effective in diverse environments, from household to industrial applications. |

| Improved airflow | Open structure enhances cooling efficiency and stable temperature maintenance. |

How They Work in Cooling Systems

Wire tube condensers play a critical role in refrigeration. Their primary function is to condense high-temperature refrigerant gas into a high-pressure liquid. This process releases significant heat, which the condenser dissipates efficiently. I’ve noticed that their open structure enhances airflow, allowing quicker heat dissipation. This design reduces energy consumption and improves the overall performance of cooling systems.

Benefits of Wire Tube Condensers

Improved Energy Efficiency

Wire tube condensers stand out for their energy efficiency. They have a 50% higher heat transfer coefficient compared to traditional plate condensers. This efficiency reduces the workload on refrigeration systems, leading to lower energy consumption. I’ve observed how this feature not only saves energy but also ensures consistent cooling performance.

Cost-Effectiveness and Durability

These condensers offer significant cost savings. Their design optimizes heat transfer, which lowers electricity bills over time. Additionally, their construction with durable materials like Bundy tubes ensures long-lasting performance. I believe this combination of cost-effectiveness and durability makes them an excellent investment for both residential and commercial applications.

Reduced Environmental Footprint

Wire tube condensers contribute to a greener future. Their compatibility with eco-friendly refrigerants minimizes environmental harm. By reducing energy consumption, they also lower carbon emissions. Companies like Ningbo Senjun New Materials Co., Ltd. are at the forefront of this innovation. Senjun’s focus on sustainable designs ensures that these condensers meet modern environmental standards while maintaining high performance.

Innovations in Wire Tube Condenser Design

Integration with Wireless Monitoring Systems

I’ve noticed how wireless monitoring systems are transforming refrigeration. These systems allow real-time tracking of condenser performance. For example, sensors can measure temperature and pressure levels, sending data to a central system or even a smartphone. This innovation makes it easier to detect issues early, reducing downtime and maintenance costs. Smart technology integration also enables predictive maintenance. By analyzing data trends, the system can alert users before a problem occurs. This proactive approach ensures consistent performance and extends the lifespan of the condenser.

Companies like Ningbo Senjun New Materials Co., Ltd. are embracing these advancements. Senjun’s focus on innovation ensures their wire tube condensers remain compatible with modern IoT technologies. This integration not only improves operational reliability but also aligns with the growing demand for smart cooling solutions.

Adoption of Eco-Friendly Refrigerants

The shift to eco-friendly refrigerants is another exciting development. Traditional refrigerants harm the environment, but modern alternatives like CO2 and hydrocarbons offer a sustainable solution. Wire tube condensers now support these refrigerants, reducing their environmental impact. I’ve seen how this compatibility helps businesses meet stricter environmental regulations while maintaining high efficiency.

Senjun leads the way in designing condensers that work seamlessly with these refrigerants. Their commitment to sustainability ensures that their products contribute to a greener future. By adopting eco-friendly designs, they help reduce refrigerant usage and lower carbon emissions, making refrigeration systems more environmentally friendly.

Enhanced Heat Transfer Efficiency

Advancements in materials and design have significantly improved heat transfer efficiency. For instance, new copper alloys enhance thermal conductivity and resist corrosion. I’ve observed how these materials maximize surface area contact, allowing faster and more efficient heat dissipation. Compact and lightweight designs also save space without compromising performance. Additionally, improved manufacturing processes, like laser welding, create durable joints that prevent leaks and extend the condenser’s lifespan.

Senjun incorporates these innovations into their wire tube condensers. Their use of advanced materials and optimized designs ensures lower energy consumption and greater durability. These enhancements not only improve performance but also make refrigeration systems more cost-effective and reliable.

Tip: Choosing condensers with advanced features like these can significantly reduce energy bills and maintenance costs over time.

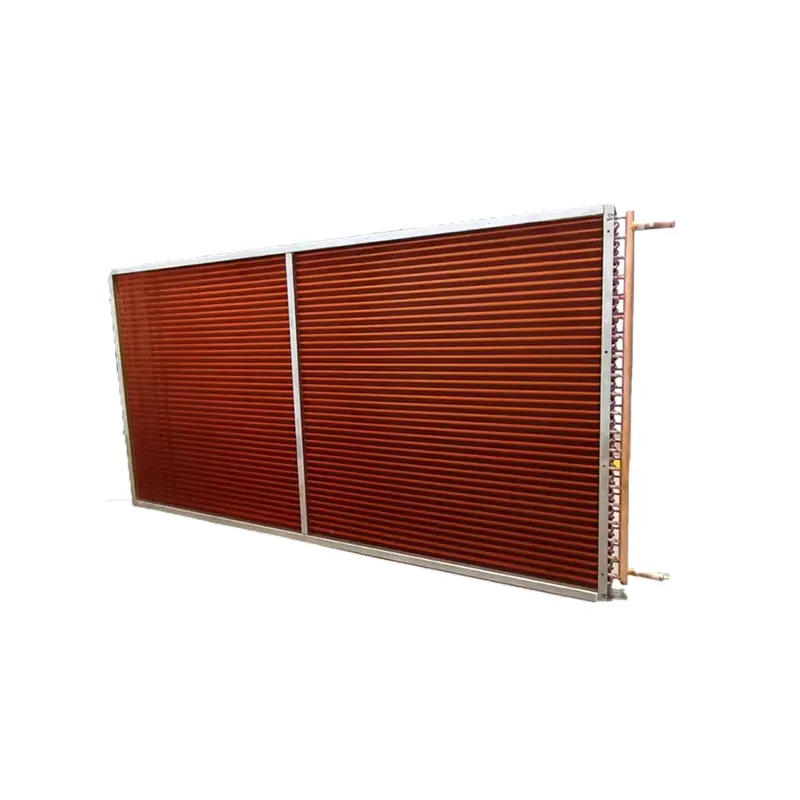

Heat Exchangers: Optimizing Heat Transfer

The Role of Heat Exchangers in Refrigeration

Heat exchangers play a vital role in refrigeration systems. They transfer heat between two fluids while keeping them separate, which enhances efficiency and reduces costs. I’ve seen how this process helps optimize energy use in cooling systems. By recovering and reusing thermal energy, heat exchangers lower energy consumption and operating expenses. Their ability to minimize environmental impact makes them indispensable in modern refrigeration.

In my experience, heat exchangers are critical for improving system performance. They ensure that cooling systems operate efficiently by maintaining optimal temperature levels. This not only saves energy but also extends the lifespan of the equipment. Companies like Ningbo Senjun New Materials Co., Ltd. specialize in developing advanced copper aluminum fin heat exchangers. These products are used in refrigerators, freezers, and even medical cooling systems, showcasing their versatility and importance.

Types of Heat Exchangers Used in Cooling Systems

Different types of heat exchangers serve various purposes in refrigeration. Each design offers unique benefits, depending on the application.

- Air Cooled Heat Exchangers: These use fin tubes exposed to air for cooling. Fans often assist in forced convection, making them common in HVAC systems.

- Shell and Tube Heat Exchangers: These consist of tubes within a shell, allowing heat transfer between fluids inside and outside the tubes. They are widely used in industrial processes.

- Regenerative Heat Exchangers: These transfer heat between two fluids and are ideal for applications requiring heat recovery.

Advantages of Heat Exchangers

Enhanced Energy Savings

Heat exchangers significantly improve energy efficiency. They enable efficient heat transfer between fluids, which reduces energy consumption. I’ve noticed how regenerative heat exchangers recover waste heat from industrial processes, further enhancing system efficiency. Proper sizing and selection of heat exchangers optimize energy use across various applications, making them a cost-effective solution.

Compact Design for Modern Systems

Modern refrigeration systems demand compact and efficient components. Heat exchangers meet this need with their space-saving designs. Their small size doesn’t compromise performance, making them ideal for applications where space is limited. I’ve seen how this feature benefits industries that require high-performance cooling in tight spaces.

Compatibility with Eco-Friendly Refrigerants

The shift to eco-friendly refrigerants has made compatibility a key feature of heat exchangers. These components work seamlessly with modern refrigerants like CO2 and hydrocarbons. This reduces the environmental impact of refrigeration systems. Senjun’s copper aluminum fin heat exchangers are designed to support these refrigerants, ensuring sustainability without sacrificing efficiency.

Note: Choosing the right heat exchanger can improve energy savings, reduce costs, and support environmental goals.

Emerging Trends in Heat Exchanger Technology

Use of Small-Diameter Copper Tubes

I’ve noticed that small-diameter copper tubes are transforming heat exchanger designs. These tubes, often as small as 4mm, reduce the overall size and cost of heat exchangers. A case study by GD Midea Refrigeration Equipment Co., Ltd. showed that using these tubes significantly lowered the refrigerant charge. This means less refrigerant is needed, which makes the system more efficient and environmentally friendly. Smaller tubes also improve heat transfer efficiency by increasing the surface area for heat exchange. This innovation aligns with the growing demand for compact and sustainable cooling systems.

At Senjun, we focus on incorporating these advancements into our copper aluminum fin heat exchangers. By optimizing tube designs, we ensure our products meet modern efficiency and sustainability standards. This approach benefits industries like refrigeration and medical cooling, where space and performance are critical.

Advanced Materials for Better Performance

The use of advanced materials has revolutionized heat exchangers. I’ve seen how materials like new copper alloys enhance thermal conductivity and resist corrosion. These materials improve heat transfer while extending the lifespan of the equipment. For example, copper-aluminum combinations are lightweight yet durable, making them ideal for modern cooling systems. These innovations also reduce maintenance needs, saving time and costs for users.

Senjun leads the way in adopting these materials. Our heat exchangers, used in refrigerators and freezers, deliver reliable performance while supporting eco-friendly refrigerants. This focus on advanced materials ensures our products remain efficient and sustainable.

Integration with Smart Cooling Systems

Smart technologies are reshaping the heat exchange industry. I’ve observed how advanced sensors and automation improve system efficiency. These systems monitor temperature and pressure in real time, allowing for precise adjustments. This reduces energy consumption and enhances performance. The adoption of smart cooling systems reflects a broader trend toward integrating technology into refrigeration.

At Senjun, we embrace these innovations. Our heat exchangers are compatible with smart systems, ensuring seamless operation in modern cooling applications. This integration supports industries like medical refrigeration, where precision and reliability are essential.

Note: The shift toward natural refrigerants and renewable energy sources complements these trends. Over the past two years, demand for natural refrigerant systems has increased by 50%. This reflects a global commitment to sustainability, which Senjun actively supports through our innovative designs.

Comparing Wire Tube Condensers and Heat Exchangers to Traditional Systems

Efficiency Gains Over Conventional Condensers

I’ve observed that wire tube condensers and heat exchangers outperform traditional systems in terms of efficiency. Wire tube condensers, for instance, achieve a 50% higher heat transfer coefficient compared to conventional plate condensers. This improvement reduces energy consumption and enhances the reliability of refrigeration systems. The open design of wire tube condensers also allows for better airflow, which further optimizes cooling performance. These advancements make modern refrigeration systems more efficient and cost-effective.

Environmental Benefits Compared to Older Technologies

Modern refrigeration components like wire tube condensers and heat exchangers offer significant environmental advantages. Traditional systems often rely on refrigerants that harm the ozone layer or contribute to global warming. In contrast, wire tube condensers and advanced heat exchangers are compatible with eco-friendly refrigerants such as CO2 and ammonia. These refrigerants reduce the environmental footprint of cooling systems. I’ve seen how companies like Ningbo Senjun New Materials Co., Ltd. lead the way in designing components that align with these sustainable practices. Their focus on innovation ensures that refrigeration systems meet strict environmental standards while maintaining high performance.

Cost and Maintenance Considerations

When comparing modern and traditional refrigeration systems, cost and maintenance play a crucial role. Modern systems incorporate advanced features that reduce long-term expenses. For example:

- Advanced control systems and leak detection systems improve operational performance and reduce energy consumption.

- Heat recovery systems and variable speed drives enhance efficiency, lowering electricity bills.

- Natural refrigerants like CO2 and ammonia offer better performance and regulatory compliance but may require specialized equipment and training, which can increase initial installation and maintenance costs.

I’ve noticed that while the upfront costs of modern systems may be higher, their long-term savings and environmental benefits outweigh these initial investments. Companies like Senjun ensure their products, such as wire tube condensers and copper aluminum fin heat exchangers, deliver durability and efficiency, making them a smart choice for both residential and commercial applications.

Future Trends and Innovations in Refrigeration

Integration with Eco-Friendly Refrigerants

I’ve noticed a growing shift toward eco-friendly refrigerants in the refrigeration industry. These alternatives, like CO2 refrigerants, offer a sustainable solution with a Global Warming Potential (GWP) of just 1. CO2 is non-toxic, non-flammable, and doesn’t harm the ozone layer. Systems like Zero Zone's ColdLoop™ have even reduced refrigerant leakage by up to 20%, showcasing the potential of these technologies. Another exciting development is thermoelectric cooling, which uses the Peltier effect to cool without chemical refrigerants. IBM-Samsung’s Photonic Cooling Platform, for instance, relies solely on water for cooling. Magnetic refrigeration, which uses the magnetocaloric effect, also holds promise, though it still faces technical challenges.

At Ningbo Senjun New Materials Co., Ltd., we focus on designing wire tube condensers and copper aluminum fin heat exchangers that are compatible with these eco-friendly refrigerants. This ensures our products meet modern environmental standards while maintaining high performance. By adopting these refrigerants, businesses can reduce their carbon footprint and comply with stricter regulations.

Use of Advanced Materials for Better Performance

Advanced materials are revolutionizing refrigeration systems. I’ve seen how innovations like copper alloys enhance thermal conductivity and resist corrosion, improving heat transfer and extending equipment lifespan. Variable speed drives also play a key role by adjusting component speeds to match cooling demands, significantly reducing energy consumption. Leak detectors provide immediate alerts for refrigerant leaks, minimizing energy waste and preventing system failures. Heat recovery systems capture expelled heat for reuse, lowering utility costs and boosting efficiency.

At Senjun, we integrate these advancements into our products. Our copper aluminum fin heat exchangers, used in refrigerators and medical cooling systems, deliver reliable performance while supporting eco-friendly refrigerants. These innovations not only improve energy efficiency but also reduce maintenance needs, making our systems more cost-effective and sustainable.

Smart and IoT-Enabled Cooling Systems

Smart and IoT-enabled cooling systems are transforming refrigeration. I’ve observed how these technologies reduce energy consumption, benefiting both the environment and operational costs. Real-time monitoring allows for predictive maintenance, saving money and extending equipment life. For example, sensors track temperature and pressure, enabling precise adjustments that optimize performance. Remote management capabilities also enhance user convenience, allowing businesses to control systems from anywhere.

Senjun embraces these advancements by ensuring our heat exchangers and condensers are compatible with smart systems. This integration supports industries like medical refrigeration, where precision and reliability are critical. By adopting IoT-enabled solutions, businesses can achieve greater energy efficiency, reduce downtime, and create a more sustainable future.

Tip: Investing in smart refrigeration technology can significantly lower electricity costs and improve system reliability over time.

The Role of AI in Optimizing Refrigeration Efficiency

Artificial intelligence (AI) is revolutionizing refrigeration by enhancing efficiency and reducing energy consumption. I’ve observed how AI systems predict critical variables like humidity and temperature, which are essential for maintaining optimal cooling conditions. These predictions allow refrigeration systems to adjust dynamically, ensuring consistent performance. For instance, AI employs mathematical optimization frameworks to determine the best operating conditions. This approach minimizes energy use while maintaining the desired temperature levels.

AI doesn’t just stop at predictions. It actively balances energy sources to reduce costs. I’ve seen reports where AI solutions have cut total energy expenses by over 10%. This is achieved by analyzing real-time data and making precise adjustments to the system. These advancements make AI an indispensable tool for modern refrigeration. By integrating AI, businesses can achieve significant energy savings and improve the reliability of their cooling systems.

Contributions of Companies Like Senjun

Development of Wire Tube Condensers and Copper Aluminum Fin Heat Exchangers

Ningbo Senjun New Materials Co., Ltd. has made remarkable strides in refrigeration technology. Their expertise lies in designing innovative wire tube condensers and copper aluminum fin heat exchangers. These components are crafted with a focus on energy efficiency, durability, and advanced manufacturing techniques. I’ve noticed how their products are trusted by customers worldwide for their reliability and high performance. Senjun’s commitment to research and development ensures that their solutions meet the evolving demands of the refrigeration industry.

Applications in Refrigerators, Freezers, and Medical Cooling Systems

Senjun’s products find applications across a wide range of industries. Their wire tube condensers are vital in refrigeration systems, including freezers and industrial water dispensers. These condensers efficiently dissipate heat, ensuring stable performance even in challenging environments. I’ve also seen their use in refrigerated trucks and cold storage warehouses, where their compact design and high efficiency maintain optimal temperatures for perishable goods. Additionally, their copper aluminum fin heat exchangers are integral to medical ultra-low temperature refrigerators, ensuring precise cooling for sensitive materials.

Focus on Sustainability and Innovation

Sustainability and innovation are at the core of Senjun’s mission. They prioritize energy efficiency by designing products that reduce energy consumption by up to 30%. Their use of advanced materials and eco-friendly technologies reflects their commitment to a greener future. I’ve noticed how their innovative solutions cater to diverse applications, from household refrigerators to medical cooling systems. By emphasizing research and development, Senjun continues to lead the way in creating high-performance, reliable, and sustainable refrigeration components.

Tip: Choosing products from companies like Senjun ensures access to cutting-edge technology that balances efficiency, durability, and environmental responsibility.

Wire tube condensers and heat exchangers are revolutionizing refrigeration by tackling energy efficiency and environmental challenges. These technologies improve airflow, enhance heat dissipation, and reduce electricity consumption by up to 30%. Their ability to maintain stable temperatures ensures reliability in applications like food preservation and medical cooling.

Companies like Ningbo Senjun New Materials Co., Ltd. lead this transformation. Senjun’s innovative designs, including wire tube condensers and copper aluminum fin heat exchangers, support eco-friendly refrigerants and advanced cooling systems. As advancements continue, these technologies will shape a sustainable and efficient future for refrigeration.

Note: Investing in modern refrigeration systems not only reduces costs but also contributes to a greener planet.

FAQ

What makes wire tube condensers more efficient than traditional condensers?

Wire tube condensers excel due to their open design, which enhances airflow and heat dissipation. They achieve a 50% higher heat transfer coefficient compared to traditional plate condensers. This efficiency reduces energy consumption and ensures reliable cooling performance. Companies like Ningbo Senjun New Materials Co., Ltd. lead in designing these advanced components.

How do heat exchangers contribute to energy savings?

Heat exchangers optimize energy use by transferring heat between fluids efficiently. This process reduces energy consumption and operating costs. I’ve seen how Senjun’s copper aluminum fin heat exchangers recover waste heat, making refrigeration systems more sustainable and cost-effective.

Are wire tube condensers compatible with eco-friendly refrigerants?

Yes, wire tube condensers support eco-friendly refrigerants like CO2 and hydrocarbons. These refrigerants minimize environmental impact while maintaining high efficiency. Senjun designs their condensers to align with modern environmental standards, ensuring sustainability without compromising performance.

What industries benefit from Senjun’s refrigeration components?

Senjun’s products serve diverse industries. Their wire tube condensers and heat exchangers are used in refrigerators, freezers, medical ultra-low temperature refrigerators, and even ice makers. I’ve noticed their reliability in applications like food preservation and medical cooling systems.

How do smart technologies improve refrigeration systems?

Smart technologies enable real-time monitoring and predictive maintenance. Sensors track temperature and pressure, allowing precise adjustments that enhance efficiency. Senjun integrates these innovations into their products, ensuring compatibility with IoT-enabled systems for better performance and reduced downtime.

Tip: Choosing advanced refrigeration components from companies like Senjun ensures energy efficiency, durability, and environmental responsibility.