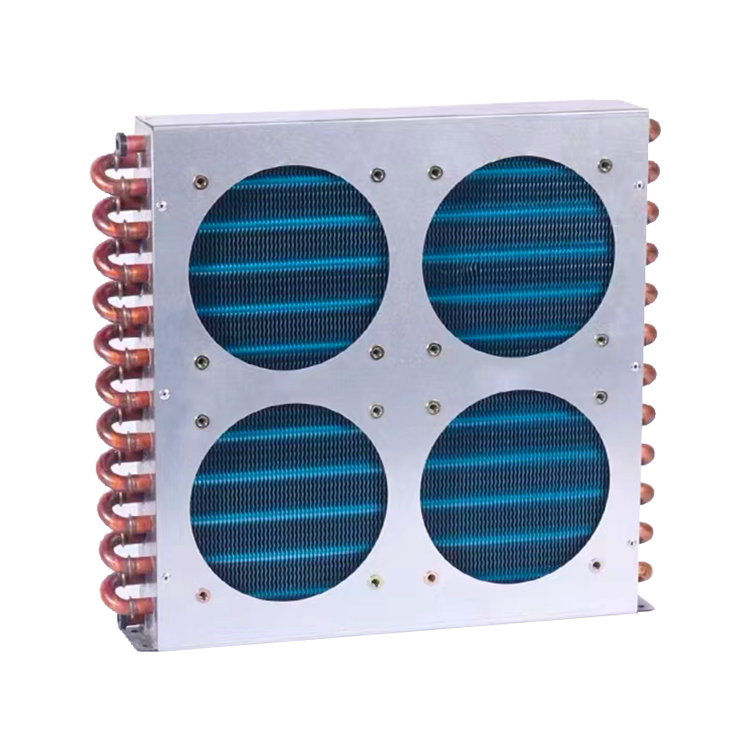

Comparative analysis: Copper tube aluminum fin condenser and traditional condenser design

2024-11-09

In the field of HVAC systems, condenser design choices can significantly impact performance, efficiency, and longevity. Among the various options available, Copper Tube Aluminum Fin Condenser (CTAF) is becoming increasingly popular. This article provides a comparative analysis of CTAF condensers versus conventional condenser designs, focusing on five key aspects: heat transfer efficiency, corrosion resistance, weight and installation, cost-effectiveness, and environmental impact.

1. Heat transfer efficiency

Heat transfer efficiency is critical in determining the overall performance of the condenser. Copper is known for its excellent thermal conductivity, allowing for superior heat exchange compared to traditional materials such as steel or even aluminum. The combination of copper tubes and aluminum fins in the CTAF condenser further increases efficiency. Aluminum fins increase heat dissipation surface area for more efficient cooling. In contrast, traditional designs often use materials that may not optimize heat transfer, resulting in reduced system performance and increased energy consumption.

2. Corrosion resistance

Corrosion resistance is a key factor in condenser life and reliability. Traditional copper condensers are susceptible to corrosion, especially in humid or salty environments. Although aluminum is generally more resistant to corrosion, it can still suffer from galvanic corrosion when in contact with copper. However, the CTAF design mitigates this problem by using aluminum fins that are less susceptible to corrosion while maintaining the superior thermal properties of copper. This combination allows the condenser to not only perform well but also last longer, reducing the need for frequent replacement.

- 3. Weight and installationWeight considerations play an important role in the installation and overall design of HVAC systems. Traditional condensers are typically made from heavier materials, which can complicate installation and increase structural support requirements. In comparison, CTAF condensers are lighter due to their use of aluminum fins, making them easier to handle and install. The reduced weight reduces installation costs and reduces stress on the building structure. Additionally, the CTAF unit’s compact design allows for more flexible placement options, further enhancing its appeal in a variety of applications.

4. Cost-Effectiveness

When evaluating cost-effectiveness, both initial investment and long-term operating costs must be considered. While CTAF condensers may cost more up front than traditional designs, their superior heat transfer efficiency reduces energy consumption over time. Reduced energy usage can result in significant savings on utility bills. Additionally, the enhanced durability and corrosion resistance of CTAF units can reduce maintenance and replacement costs, making them a more economical option in the long run.

5. Environmental impact

In today’s environmentally conscious market, the environmental impact of HVAC systems cannot be ignored. CTAF condensers are often designed with environmentally friendly refrigerants and materials, helping to reduce the carbon footprint. Their energy efficiency not only reduces greenhouse gas emissions but also aligns with global sustainability goals. On the other hand, traditional condenser designs may not offer the same level of efficiency or environmental considerations, potentially resulting in higher emissions and energy waste.

In conclusion

In conclusion, the comparative analysis of copper tube aluminum fin condenser and conventional condenser design revealed several advantages of the CTAF unit. From superior heat transfer efficiency and corrosion resistance to lighter weight, cost-effectiveness and reduced environmental impact, CTAF condensers make a compelling case for modern HVAC applications. As the industry continues to evolve, adopting innovative designs such as CTAF is critical to achieving optimal performance and sustainability in heating and cooling systems.