0102030405

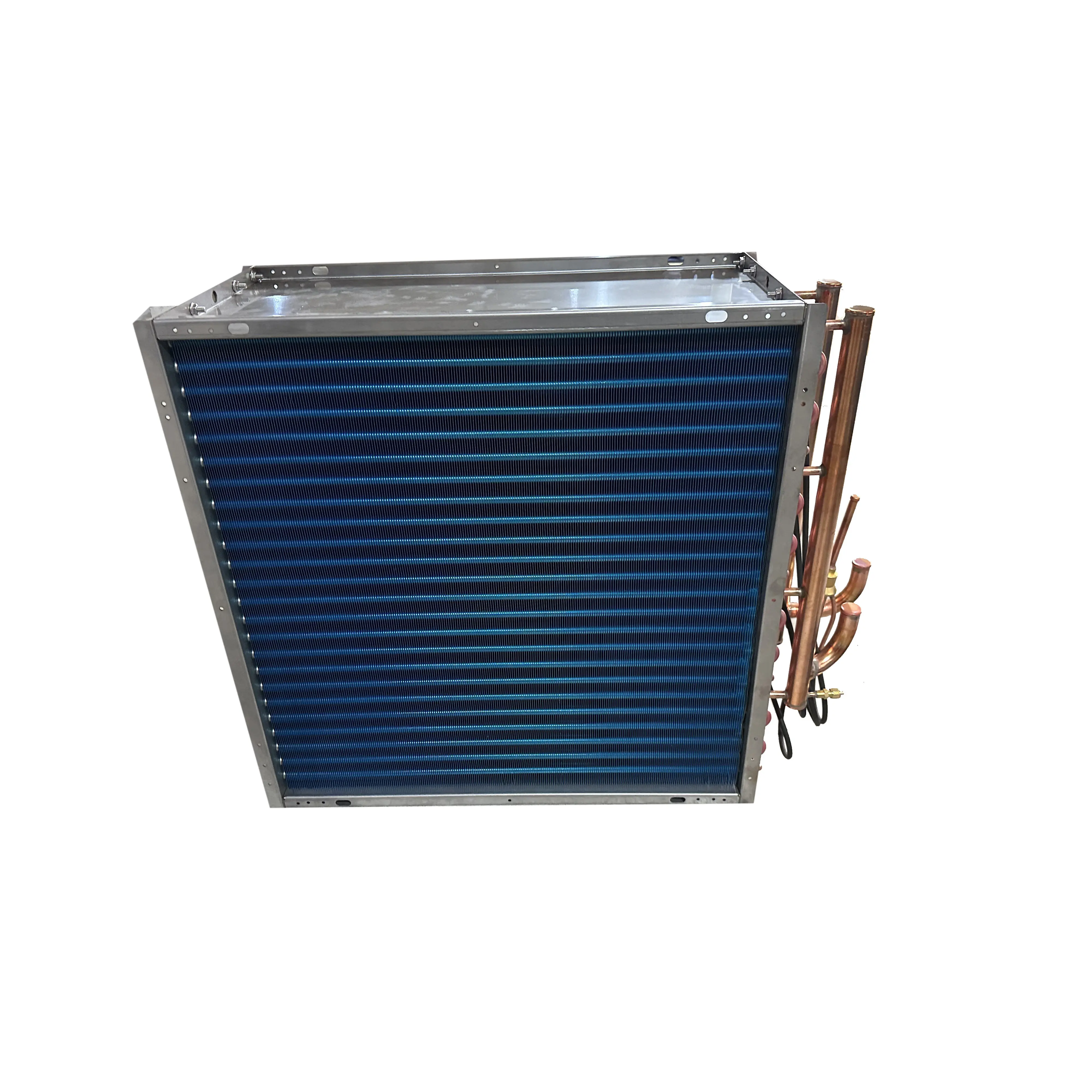

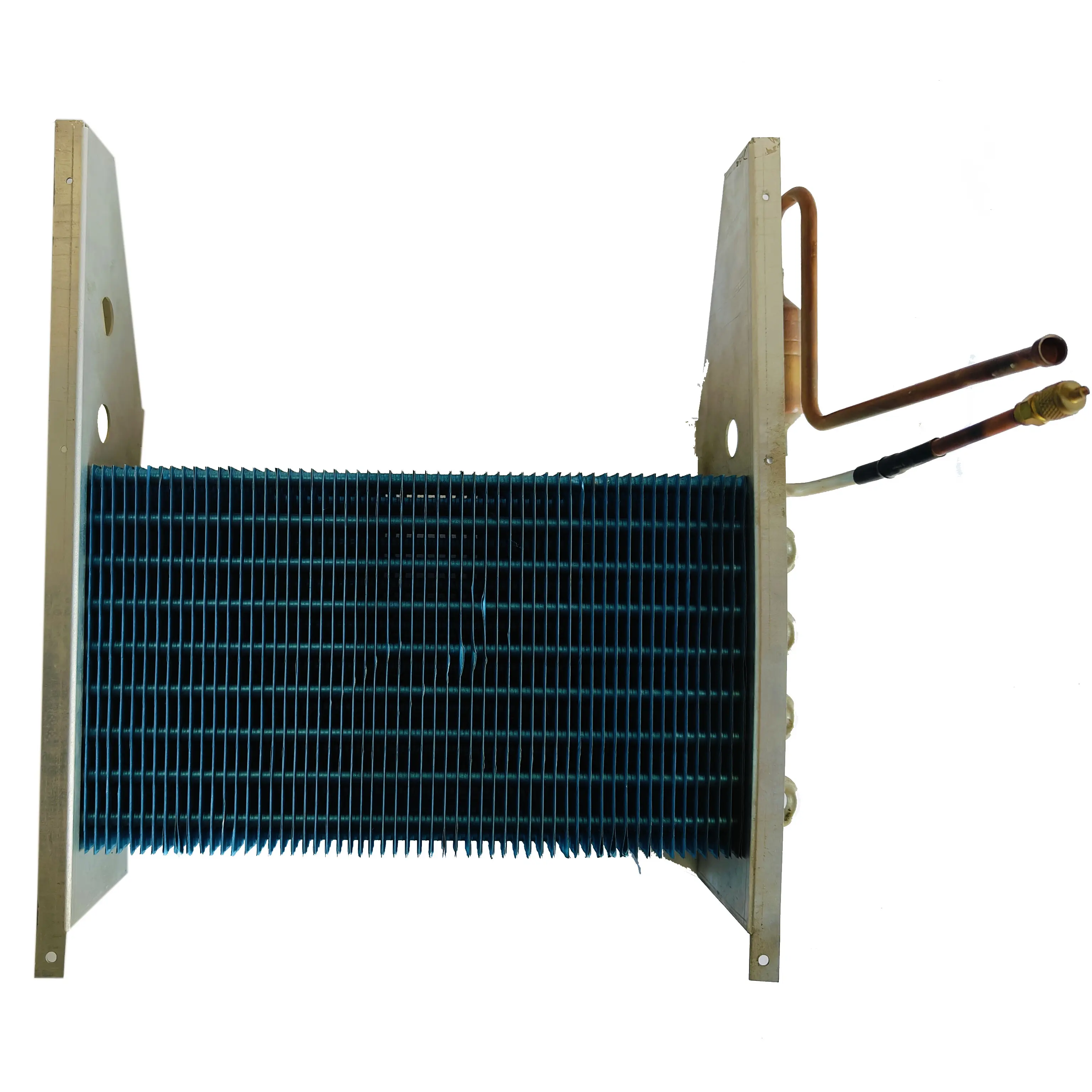

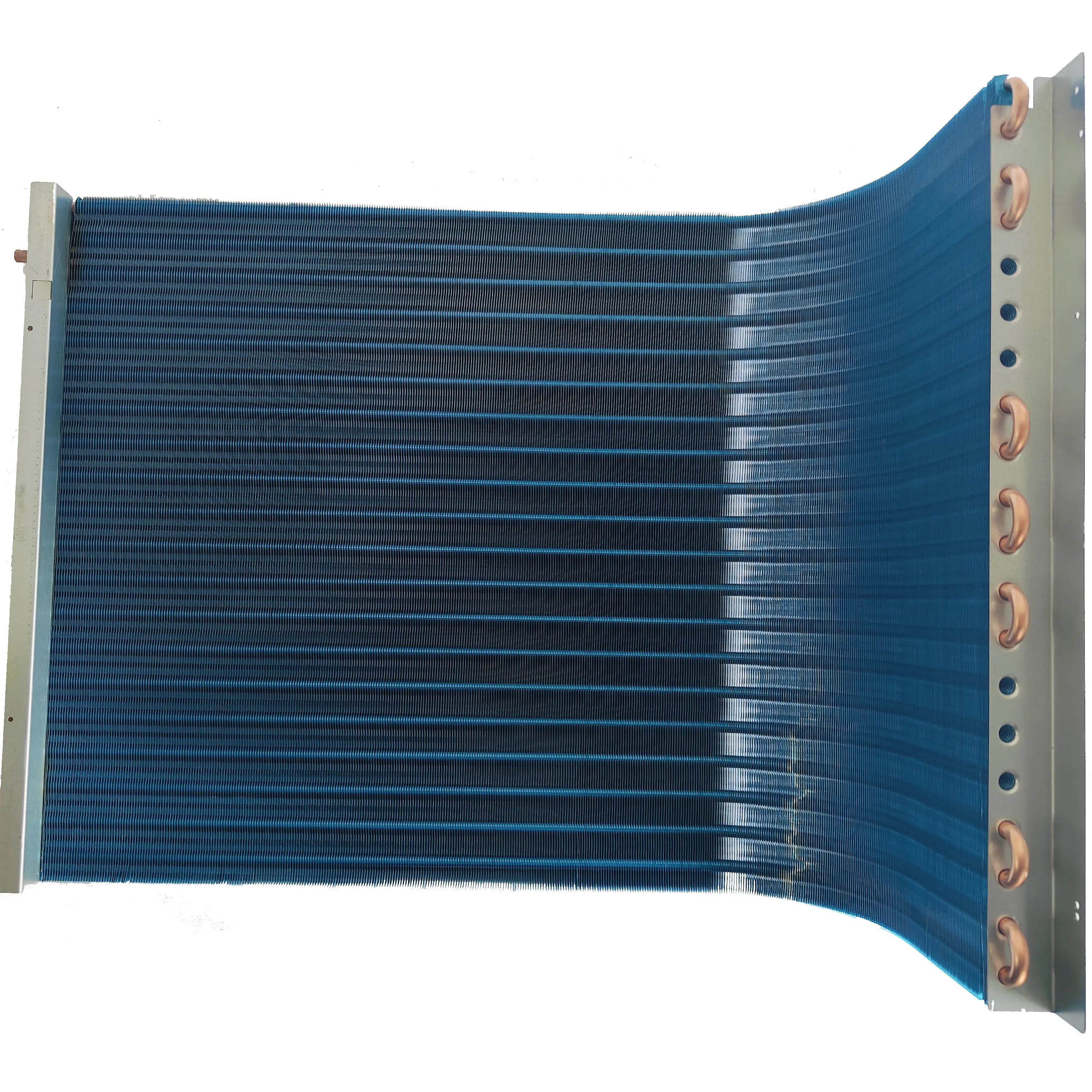

High-Efficiency Industrial Chiller Cooling Unit for Robust Performance

Product DisplaySENJUN

PRODUCT DESCRIPTIONSENJUN

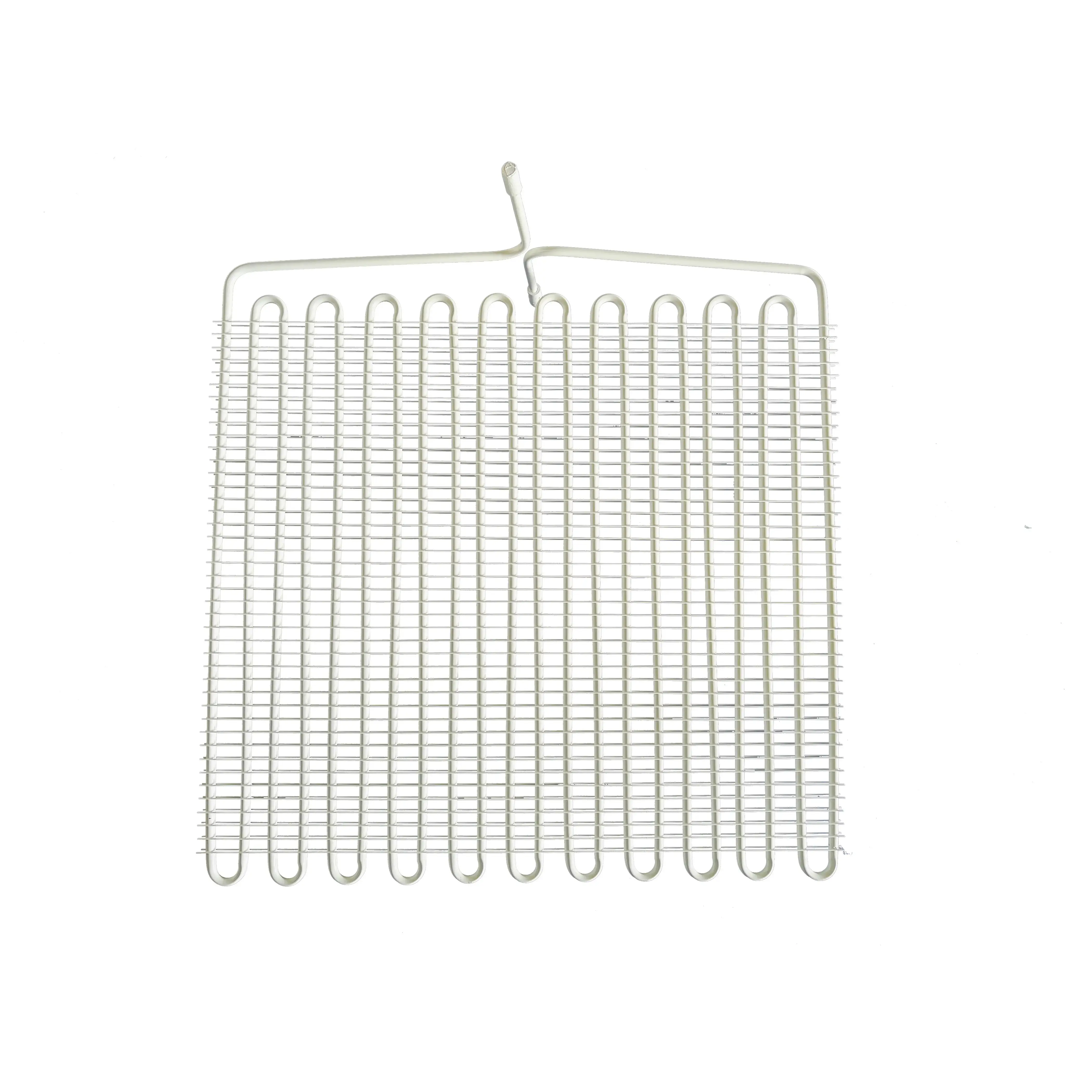

Industrial chiller cooling unit is a kind of refrigeration equipment widely used in the industrial field. It is mainly used to provide cooling water to reduce the temperature of industrial equipment, ensure the normal operation of the equipment and improve production efficiency. The refrigeration system of the industrial chiller cooling unit consists of four basic parts: compressor, condenser, throttle, and evaporator. These parts are connected into a closed system through copper tubes and filled with a certain amount of refrigerant. The following are common application scenarios;

-

1.Chemical industry

Chemical reaction cooling: In chemical synthesis reactions, many reactions are exothermic reactions, such as oxidation reactions, polymerization reactions, etc. The industrial chiller cooling unit can provide cooling for the reactor and control the reaction temperature within an appropriate range. For example, in the ammonia synthesis reaction, the reaction heat is taken away in time through the cooling unit, maintaining the reaction temperature within the optimal activity temperature range of the catalyst, and improving reaction efficiency and product quality. In the pharmaceutical process, drug synthesis reactions have stricter temperature requirements. The cooling unit can accurately control the reaction temperature according to the requirements of different drug synthesis steps to ensure the purity and efficacy of the drug.

-

2. Food and Beverage IndustryIn food processing processes, such as meat processing, dairy processing, baking, etc., industrial chiller cooling units can provide cooling for processing equipment. For example, in meat processing, cooling units can provide cooling for cutting equipment, mixing equipment, etc. to prevent food from spoiling. In dairy processing, it can provide cooling for pasteurization equipment, homogenization equipment, etc. to ensure product quality and safety. During the baking process, the cooling unit can provide cooling for ovens and other equipment, control the baking temperature, and improve the quality of baked products.

-

3. Printing industry

When the printing equipment is running at high speed, the ink drying system will generate a lot of heat. The chiller cooling unit can cool the drying system to prevent premature drying of the ink and ensure printing quality. The temperature and humidity in the printing workshop have an important impact on the quality of printed matter. This unit can adjust the temperature and humidity of the workshop environment to improve the color accuracy and clarity of printed matter.

-

4.construction industryIn the construction of large buildings, the temperature needs to be controlled during concrete pouring to prevent cracks in the concrete due to excessive temperature. The chiller cooling unit can ensure the quality of the concrete by cooling the concrete mixing water or cooling the concrete structure.