0102030405

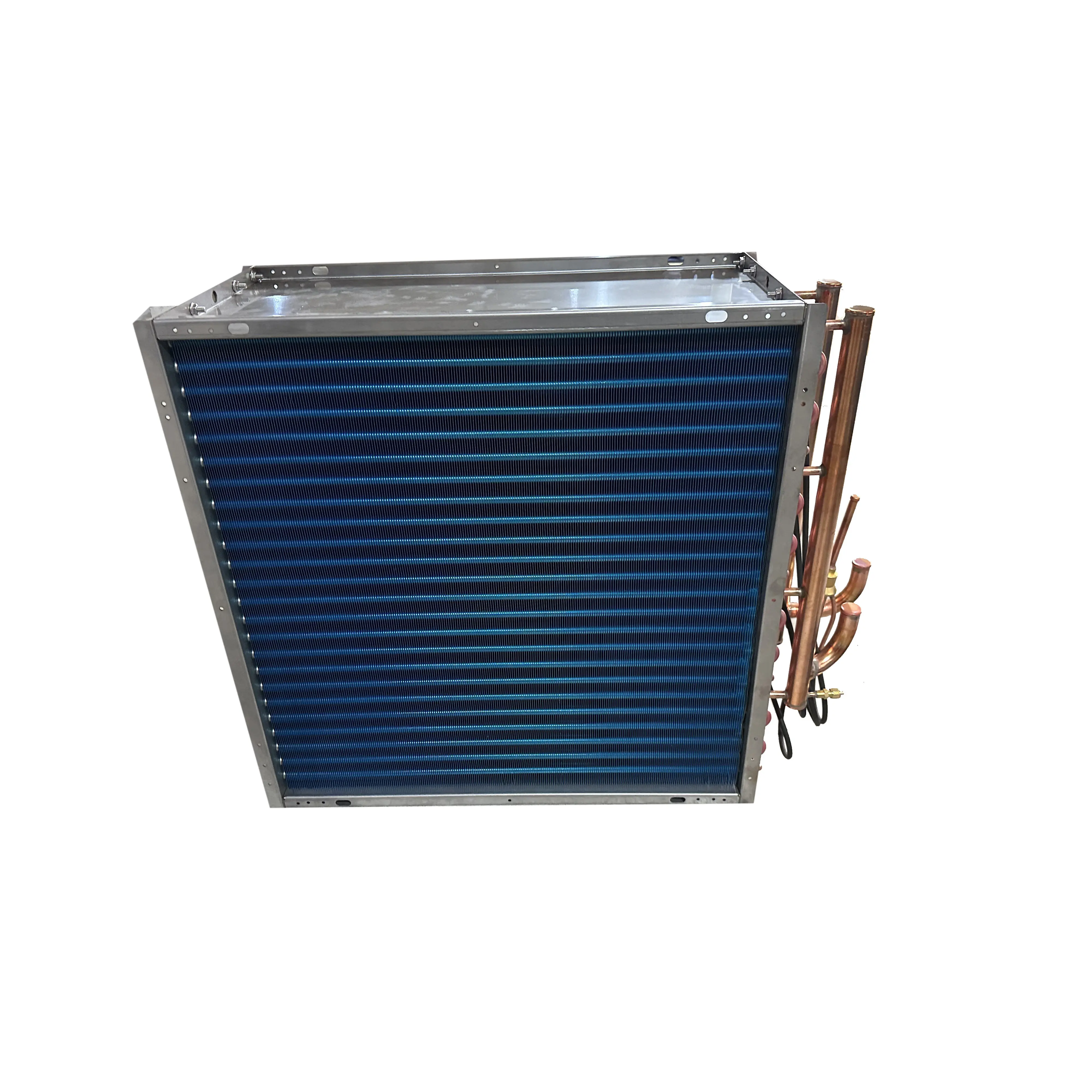

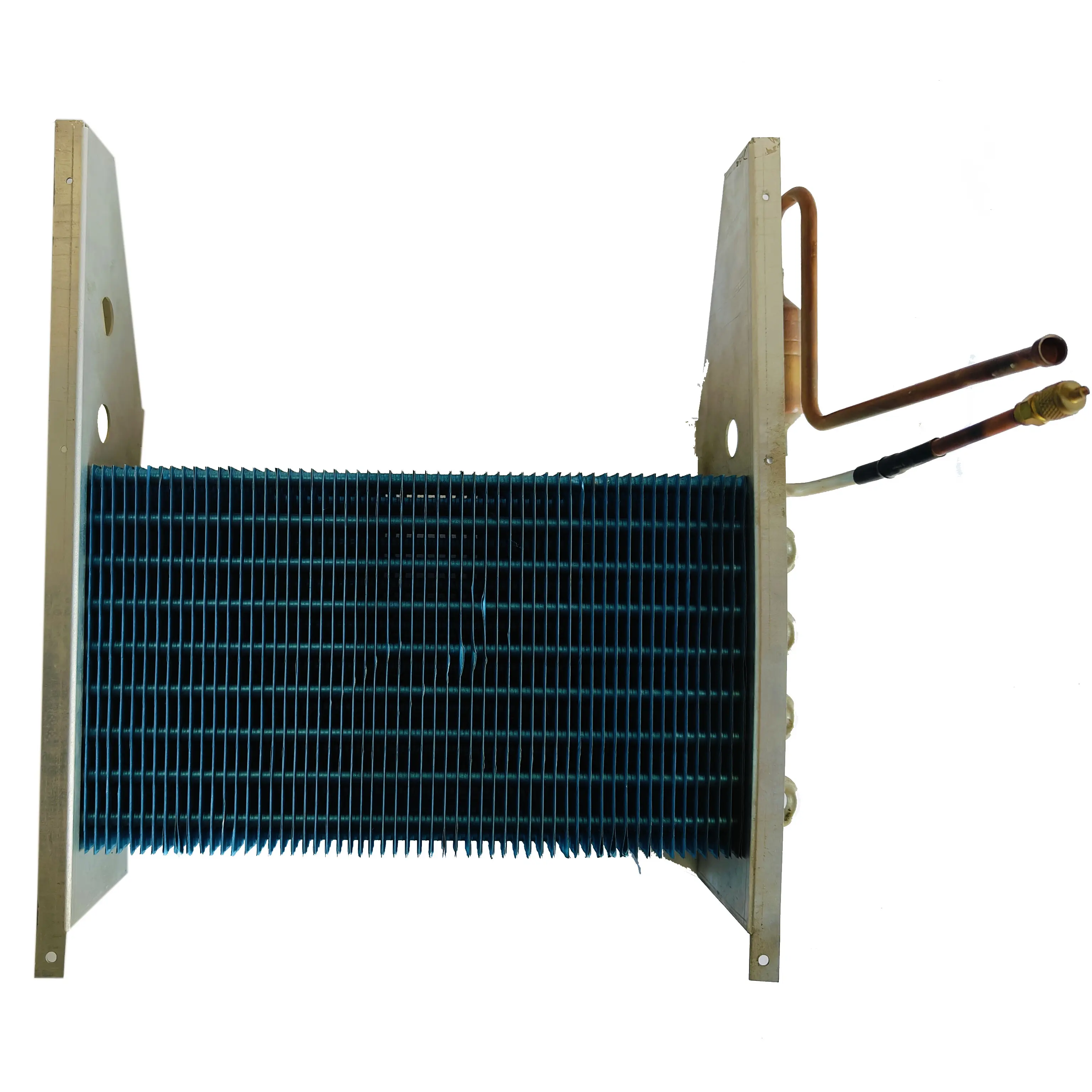

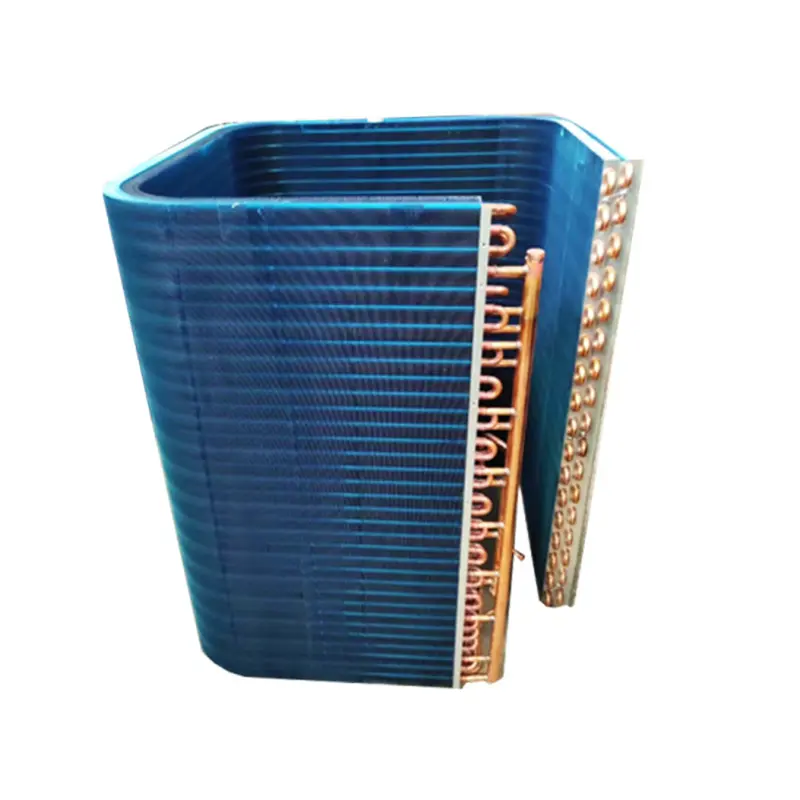

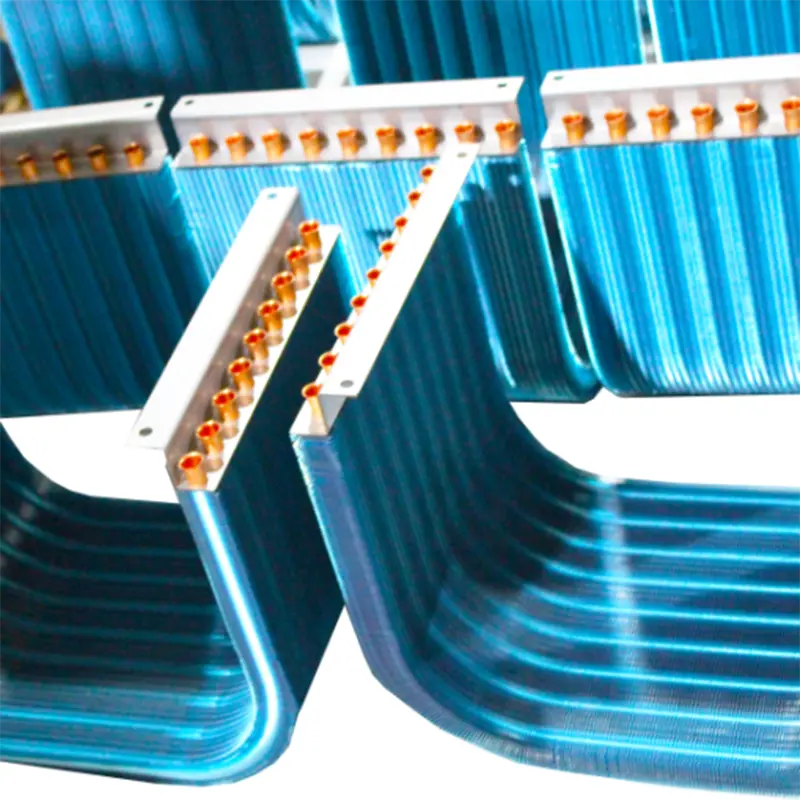

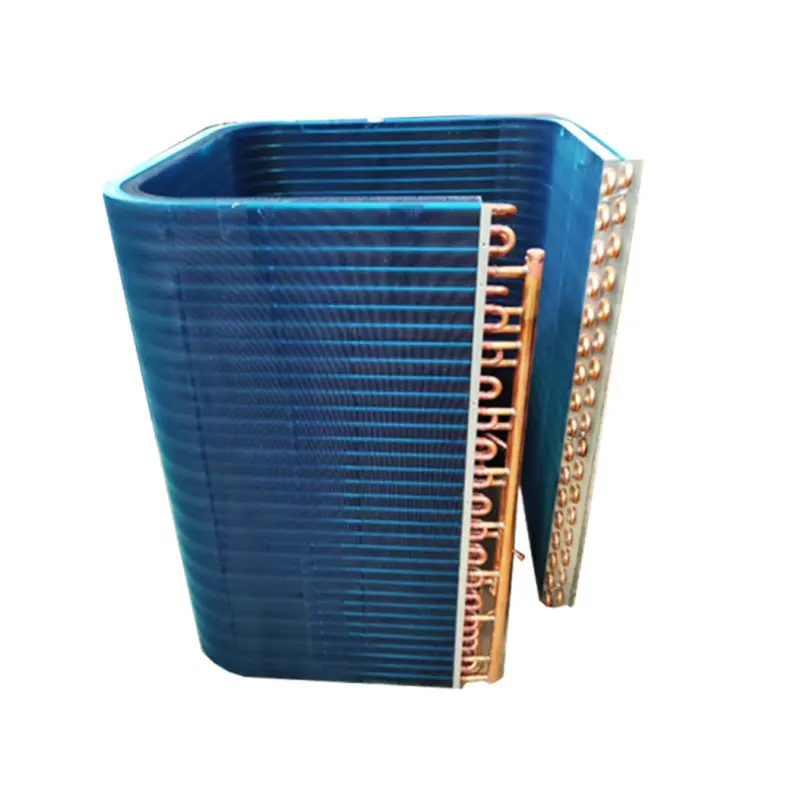

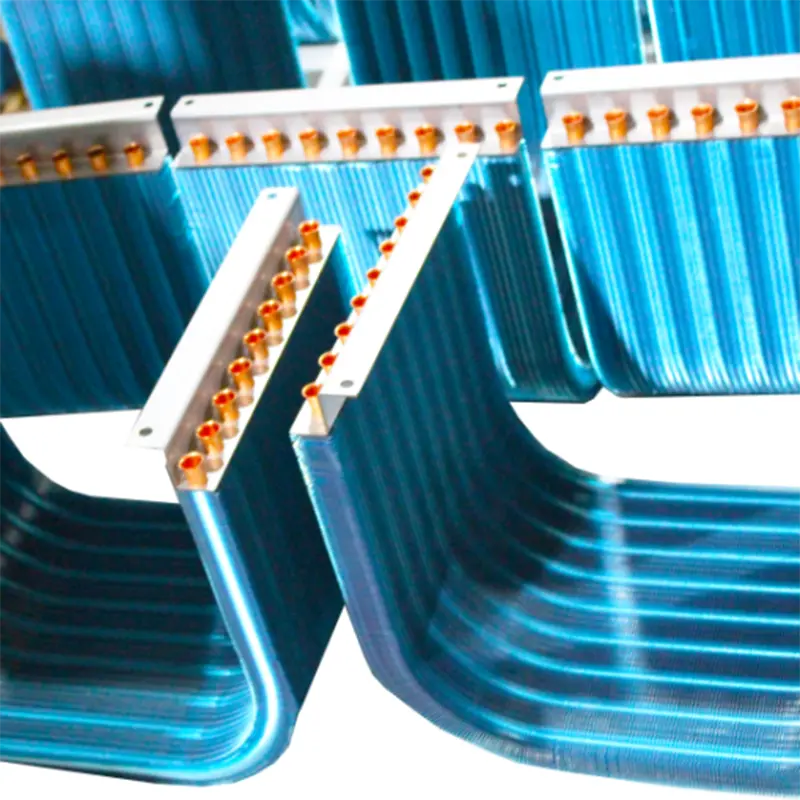

U-type finned condenser finned heat exchanger table cooler

Product DisplaySENJUN

PRODUCT DESCRIPTIONSENJUN

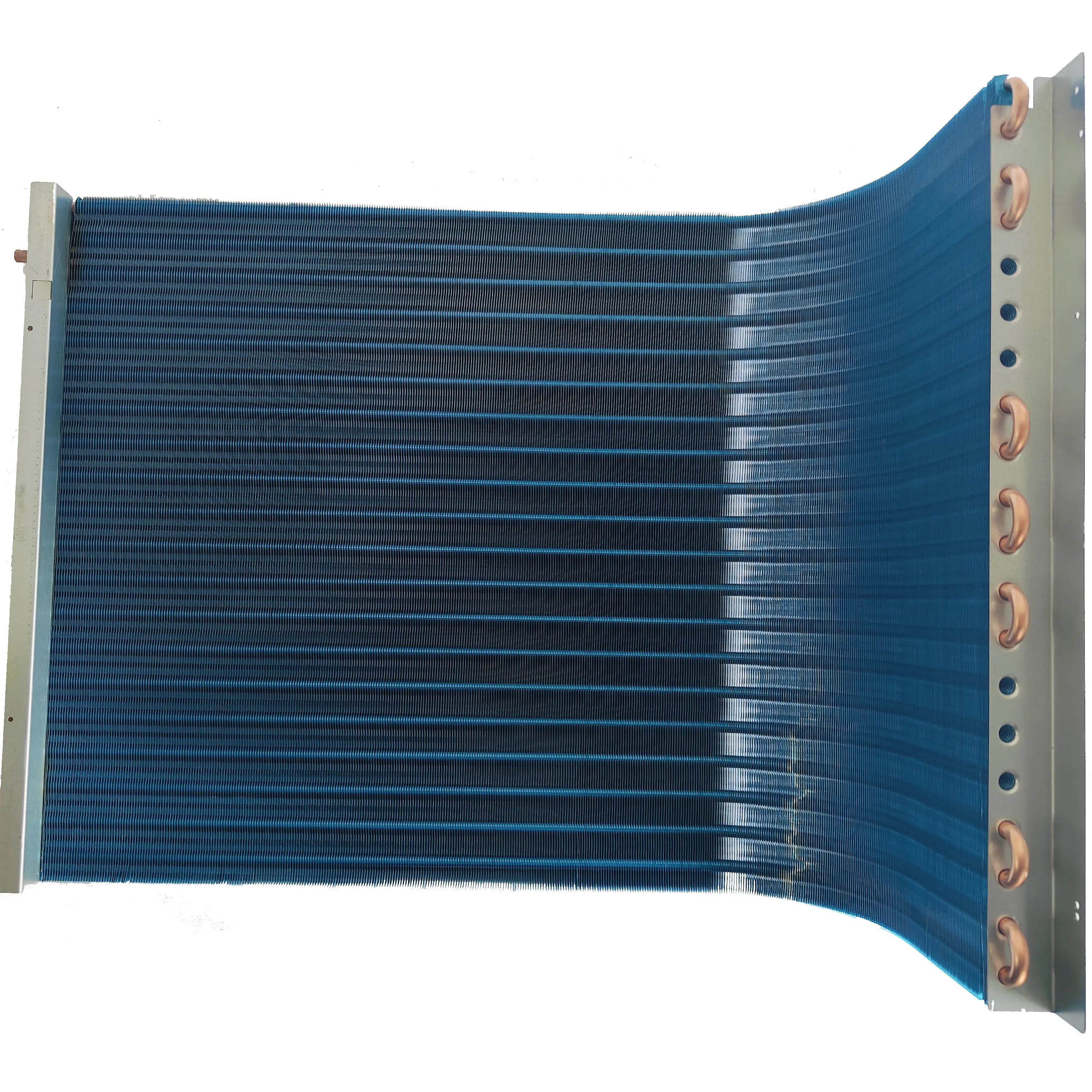

The fins are tightly packed around the U-tube, and the fins are also typically made of aluminum. Fins come in various shapes, common ones include flat fins, corrugated fins, etc. The main function of the fins is to increase the heat exchange area of the condenser. When the air flows through the fins, heat can be exchanged over a larger area, thus improving the heat exchange efficiency of the condenser.

Fin heat exchangers can be used to exchange heat between fluids of different temperatures and properties. For example, in chemical production, it can be used to heat or cool chemical raw materials. A hot chemical raw material flows in the tube and exchanges heat with the cooling medium (such as water or cold air) outside the tube through the fins to achieve the purpose of cooling; or the cold raw material is heated by exchanging heat with the heat medium.

The cooling medium circulates inside the cooler, and when an object that needs to be cooled (such as an experimental sample or electronic equipment) comes into contact with the cooling medium, heat is transferred from the object to the cooling medium. The cooling medium flows to the heat dissipation unit with the heat, and the heat is dissipated to the surrounding environment through fans or heat sinks.

Fin heat exchangers can be used to exchange heat between fluids of different temperatures and properties. For example, in chemical production, it can be used to heat or cool chemical raw materials. A hot chemical raw material flows in the tube and exchanges heat with the cooling medium (such as water or cold air) outside the tube through the fins to achieve the purpose of cooling; or the cold raw material is heated by exchanging heat with the heat medium.

The cooling medium circulates inside the cooler, and when an object that needs to be cooled (such as an experimental sample or electronic equipment) comes into contact with the cooling medium, heat is transferred from the object to the cooling medium. The cooling medium flows to the heat dissipation unit with the heat, and the heat is dissipated to the surrounding environment through fans or heat sinks.

-

1.U-shaped fin condenser application scenarios

Household air conditioner

Split air conditioner: In the outdoor unit of the split air conditioner, the U-shaped fin condenser is one of the core components. It dissipates the heat absorbed indoors through heat exchange with outdoor air. When the air conditioner runs in the cooling mode, the high-temperature and high-pressure refrigerant gas enters the U-shaped fin condenser from the compressor. Under the action of the fan, the outdoor air quickly flows through the fins, taking away the heat of the refrigerant and condensing it into liquid to maintain the normal operation of the air conditioning refrigeration cycle. For example, when using air conditioning in summer, the U-shaped fin condenser can efficiently discharge indoor heat to the outdoors to ensure indoor coolness.

- 2. Application scenarios of fin heat exchangers Industrial field Petrochemical industry: In the petroleum refining process, fin heat exchangers are used for preheating and cooling of crude oil. For example, before the crude oil enters the distillation tower, heat is exchanged with other hot fluids through a fin heat exchanger to increase the temperature of the crude oil and reduce energy consumption. At the same time, in the production process of some chemical products, such as synthetic ammonia, methanol, etc., fin heat exchangers are used for heating and cooling of reaction gases or liquids to control the temperature and rate of chemical reactions.

-

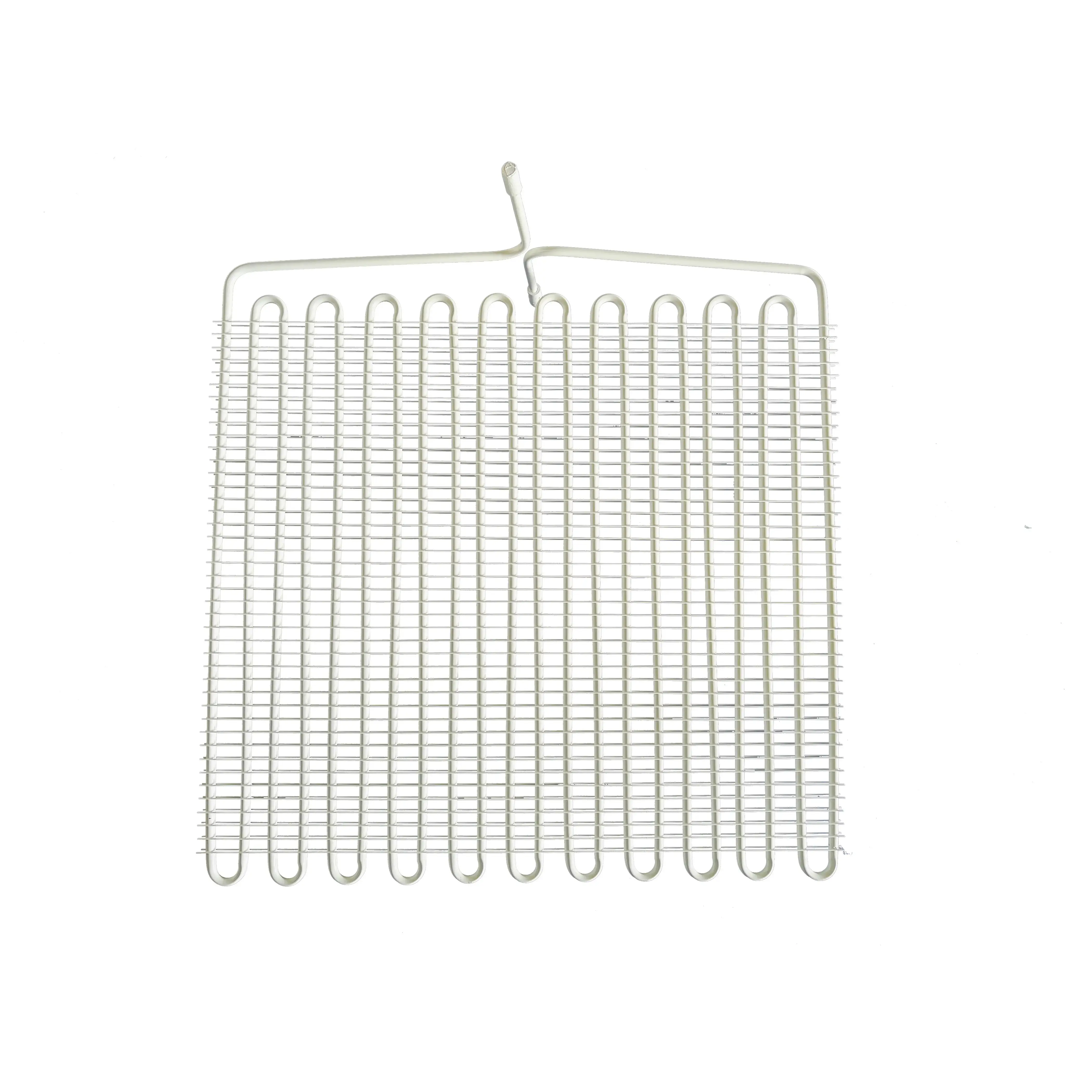

3. Desktop cooler application scenarios

Laboratory applications

Cooling of chemical experiment instruments: In chemical laboratories, many instruments, such as rotary evaporators, reaction kettles, etc., generate heat during operation and require cooling to ensure the accuracy and safety of experiments. Benchtop coolers can provide cooling for these instruments to prevent excessive temperatures from causing experimental failure or instrument damage. For example, when performing distillation experiments on organic solvents, the rotary evaporator is cooled by a benchtop cooler, allowing the solvent to be evaporated and recovered at a lower temperature.

- 4. Laboratory pool

In some scientific experiments, the temperature and humidity of the pool need to be strictly controlled to ensure the accuracy and reliability of the experimental results. For example, in biological experiments, specific temperature and humidity conditions may be a key factor in maintaining the viability of cell cultures or biological samples. Prevent the impact of changes in temperature and humidity on precision instruments and equipment in the laboratory, extend the service life of the equipment, and reduce equipment maintenance and replacement costs. Provide a comfortable working environment to avoid harm to the health of experimenters due to temperature and humidity discomfort, and improve work efficiency and accuracy of experimental operations.