Why Heat Pump Drying Units Are a Game-Changer for Food Preservation

When it comes to food preservation, the heat pump drying unit stands out as a revolutionary technology. Unlike traditional drying methods, it offers unmatched efficiency and precision. For example, these units consume less energy, which reduces utility bills. They also operate at lower temperatures, preserving the quality of delicate foods like fruits and herbs.

Here’s a quick comparison of the benefits:

| Benefit | Description |

|---|---|

| Energy Efficiency | Uses significantly less energy, lowering costs. |

| Versatility | Adapts to various drying needs with customizable settings. |

| Reduced Heat Emission | Produces cooler air, maintaining a stable environment. |

| Quiet Operation | Operates quietly, making it ideal for diverse applications. |

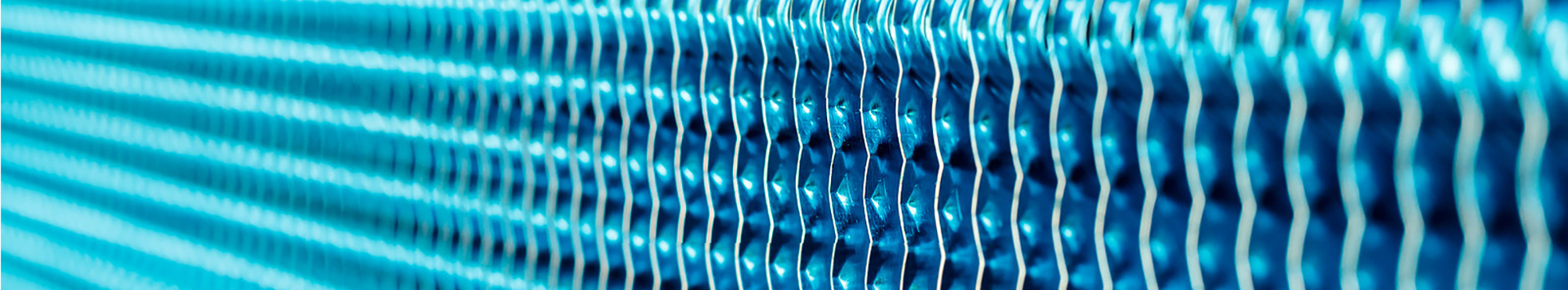

The SENJUN heat pump drying unit exemplifies these advantages. Its advanced design, rooted in expertise from condenser manufacturing, ensures optimal performance. This innovation not only preserves food but also supports sustainable practices.

Key Takeaways

- Heat pump dryers use less energy, about 50% less than regular dryers. This helps save money on bills over time.

- They work at lower heat, keeping food's nutrients, taste, and quality safe. This is great for foods like fruits and herbs.

- The SENJUN heat pump dryer has settings you can adjust. It works well for many foods, like fruits and grains.

- This technology lowers carbon emissions, making it better for the environment.

- Buying a heat pump dryer helps food last longer and stay fresh. This reduces food waste.

How Heat Pump Drying Units Save Energy

I’ve always been amazed by how much energy a heat pump drying unit can save. These units use a closed-loop system that recycles heat during the drying process. This design allows them to consume up to 50% less energy compared to conventional drying technologies. For example, studies show that some models can reduce energy use by as much as 75%. This efficiency makes them a smart choice for anyone looking to cut down on energy bills while preserving food effectively.

Here’s a quick look at energy savings from different sources:

| Source | Energy Savings |

|---|---|

| Energy Star | 28% |

| Zero Energy Project | 75% or more |

| NRDC | 50% |

| Loyal Machine | 50% |

This data highlights how heat pump drying units outperform traditional methods in energy efficiency.

Lower Operating Costs for Long-Term Savings

Energy savings directly translate to lower operating costs. I’ve noticed that businesses and households using heat pump drying units enjoy significant long-term savings. These units require less electricity to operate, which reduces monthly utility expenses. Over time, the cost difference becomes even more noticeable. For instance, a unit that uses 30% less energy than a conventional dryer can save hundreds of dollars annually. This makes it a cost-effective investment for both small-scale and large-scale operations.

SENJUN’s High Energy Efficiency Ratio (COP)

The SENJUN heat pump drying unit takes energy efficiency to the next level. Its energy efficiency ratio (COP) ranges from 2.5 to 5. This means that for every unit of energy consumed, the unit produces multiple units of drying energy. I find this feature particularly impressive because it ensures optimal performance while keeping energy consumption low. Whether you’re drying fruits, grains, or medicinal materials, SENJUN’s advanced design guarantees efficient and reliable results.

Superior Food Quality Preservation

Precise Temperature Control for Delicate Foods

I’ve always found that delicate foods like fruits and herbs require precise temperature control during drying. Too much heat can destroy their natural flavors and textures. A heat pump drying unit solves this problem by operating at lower temperatures. This gentle approach ensures that sensitive foods retain their original qualities. It also allows for better control over moisture levels, which is essential for preserving food. I’ve seen how this technology can handle even the most fragile ingredients without compromising their quality.

Gentle Drying Process to Retain Nutrients and Flavor

The drying process plays a huge role in maintaining the nutritional value of food. Traditional methods often use high heat, which can strip away essential nutrients. I’ve noticed that heat pump drying units use a gentler process. They recycle heat and energy, which prevents overheating. This method locks in nutrients and preserves the natural flavors of food. For example, dried fruits processed with this technology taste fresher and more vibrant. It’s amazing how much better the results are compared to older drying techniques.

SENJUN’s Customizable Temperature Range for Optimal Results

The SENJUN heat pump drying unit takes food preservation to the next level. Its customizable temperature range, from 30°C to 85°C, allows users to tailor the drying process for different foods. I’ve seen how this flexibility ensures optimal results for a variety of applications. Whether drying grains, fruits, or medicinal herbs, the unit delivers consistent quality. The ability to adjust settings makes it a versatile tool for anyone looking to preserve food effectively. It’s a game-changer for both small-scale and large-scale operations.

With its precise control and gentle drying process, the SENJUN heat pump drying unit ensures food retains its nutrients, flavor, and texture. This makes it an essential tool for modern food preservation.

Environmental Benefits

Reduced Carbon Footprint with Heat Pump Technology

I’ve always been impressed by how heat pump drying units contribute to reducing carbon emissions. These units recycle heat that would otherwise be wasted in traditional drying methods. By recovering latent and sensible heat from the drying air, they make the process more energy-efficient. This means less energy is consumed, which directly lowers carbon emissions.

Heat pump drying has the capacity to recover latent and sensible heat by condensing moisture from the drying air, which other drying methods cannot do. This increases energy effectiveness substantially as a result of heat recovery, enabling drying at lower temperatures and lower costs.

Additionally, these units can operate using carbon-pollution-free electricity. This makes them an excellent choice for anyone looking to adopt eco-friendly practices. I’ve seen how this technology not only reduces environmental impact but also enhances product quality by allowing for lower temperature drying.

Minimizing Food Waste Through Better Preservation

Food waste is a major issue, and I’ve noticed how better preservation methods can make a big difference. Heat pump drying units excel at maintaining the quality of food, which helps reduce spoilage. Studies show that households using advanced preservation methods, like freezing or drying, experience significantly less food waste. For example, frozen food options have been shown to reduce waste by 47% compared to fresh food categories.

Without effective preservation, food often spoils before it can be consumed. Projections suggest that without frozen food options, the EU would see an increase of 5.5 million tonnes of household food waste annually. This highlights the critical role of technologies like heat pump drying units in minimizing waste. By extending the shelf life of food, these units help ensure that less food ends up in landfills.

SENJUN’s Sustainable Design for Eco-Friendly Operations

The SENJUN heat pump drying unit stands out for its sustainable design. I’ve noticed how its closed-loop system not only saves energy but also reduces environmental impact. The unit recycles heat within the system, which minimizes energy loss. This design ensures that drying processes are both efficient and eco-friendly.

Its ability to operate at lower temperatures further enhances its sustainability. Lower temperatures mean less energy is required, which reduces the overall carbon footprint. Whether you’re drying grains, fruits, or medicinal herbs, SENJUN’s innovative design supports environmentally responsible operations. I believe this makes it a valuable tool for anyone committed to sustainability.

Versatility and Adaptability

Suitable for Various Food Types and Applications

I’ve always been amazed by how versatile a heat pump drying unit can be. This technology works exceptionally well for drying a wide range of foods. Fruits and vegetables, in particular, benefit greatly from this method. The gentle drying process preserves their natural flavors and textures while reducing moisture effectively.

Some of the foods that can be dried using this technology include:

- Apples

- Bananas

- Strawberries

- Tomatoes

- Bell peppers

This versatility makes it an excellent choice for both home use and commercial food processing. Whether you’re preserving seasonal produce or preparing ingredients for packaged snacks, this unit delivers consistent results every time.

SENJUN’s Adjustable Settings for Diverse Needs

The SENJUN heat pump drying unit stands out because of its customizable settings. I’ve seen how its adjustable temperature range, from 30°C to 85°C, allows users to tailor the drying process for different foods. This flexibility ensures that each product gets the precise treatment it needs. For example, delicate fruits like strawberries require lower temperatures to retain their nutrients, while grains may need higher settings for effective drying.

The unit’s air volume capabilities, ranging from 500m³/h to 2000m³/h, further enhance its adaptability. This feature makes it suitable for both small-scale operations and large-scale industrial applications. I believe this level of customization is what sets SENJUN apart from other drying technologies.

Applications in Agriculture, Food Processing, and More

I’ve noticed that heat pump drying units have a wide range of applications in agriculture and food processing. They are particularly effective for drying fruits and vegetables, enhancing product quality while using less energy. This technology also works well under humid conditions and at lower temperatures, making it ideal for heat-sensitive materials like medicinal herbs.

In addition, it can be combined with other drying techniques, such as solar drying or infrared drying, to improve efficiency and reduce costs. This makes it a valuable tool for farmers, food manufacturers, and even researchers working with specialized materials. Whether you’re drying grains, preparing snack foods, or preserving medicinal ingredients, this unit offers unmatched reliability and performance.

The adaptability of the SENJUN heat pump drying unit ensures it meets the diverse needs of modern food preservation, from small farms to large-scale industries.

I’ve seen how heat pump drying units transform food preservation. They combine energy efficiency, superior food quality retention, and environmental sustainability. For businesses, the long-term benefits are undeniable.

| Benefit | Description |

|---|---|

| Energy Savings | Heat pump dryers use less than 50% of the energy of conventional dryers, leading to significant utility cost reductions. |

| Reduced Operational Costs | The technology recycles air, further lowering energy needs and operational expenses. |

| Lower Environmental Impact | These dryers emit fewer greenhouse gases and use environmentally friendly refrigerants. |

Investing in a heat pump drying unit ensures lower costs, better food quality, and a smaller environmental footprint. Whether you’re preserving fruits or processing grains, this technology delivers unmatched results. Upgrade today and revolutionize your food preservation process.

FAQ

What makes heat pump drying units better than traditional dryers?

I’ve noticed that heat pump drying units use less energy and operate at lower temperatures. This helps preserve food quality while reducing costs. Their closed-loop system recycles heat, making them more efficient and eco-friendly compared to traditional drying methods.

Can I use the SENJUN heat pump drying unit for different types of food?

Yes! I’ve seen how its customizable temperature range and adjustable air volume make it suitable for drying fruits, grains, vegetables, and even medicinal herbs. This versatility ensures optimal results for a wide variety of food types and applications.

How does the SENJUN unit help reduce food waste?

The SENJUN unit extends the shelf life of food by reducing moisture effectively. I’ve observed how it preserves nutrients, flavors, and textures, preventing spoilage. This means less food gets wasted, which benefits both households and businesses.

Is the SENJUN heat pump drying unit environmentally friendly?

Absolutely! Its closed-loop system recycles heat, reducing energy consumption and carbon emissions. I’ve found that it operates at lower temperatures, which further minimizes its environmental impact. It’s a great choice for anyone committed to sustainability.

How much energy can I save with a SENJUN heat pump drying unit?

The SENJUN unit’s energy efficiency ratio (COP) ranges from 2.5 to 5. This means it produces multiple units of drying energy for every unit of energy consumed. I’ve seen users save up to 50% or more on energy costs compared to traditional dryers.