Which countries are the leading producers of copper tube aluminum fin heat exchangers?

When discussing the global leaders in producing copper tube aluminum fin heat exchangers, five countries stand out: China, India, Turkey, the United States, and Japan. Each of these nations plays a pivotal role in meeting the growing demand for efficient heat transfer solutions across industries.

China leads the market with a 35% share, driven by its robust investments in chemical, petrochemical, and HVAC sectors. India and Turkey follow closely, contributing 21% and 16% respectively, while the United States holds 17%. Japan, though lacking specific market share data, remains a key player due to its advanced manufacturing technologies.

Asia-Pacific dominates the heat exchanger market, fueled by rapid industrialization and urbanization. Countries like China and India are at the forefront, leveraging their expanding chemical industries and increasing capital expenditures to drive growth.

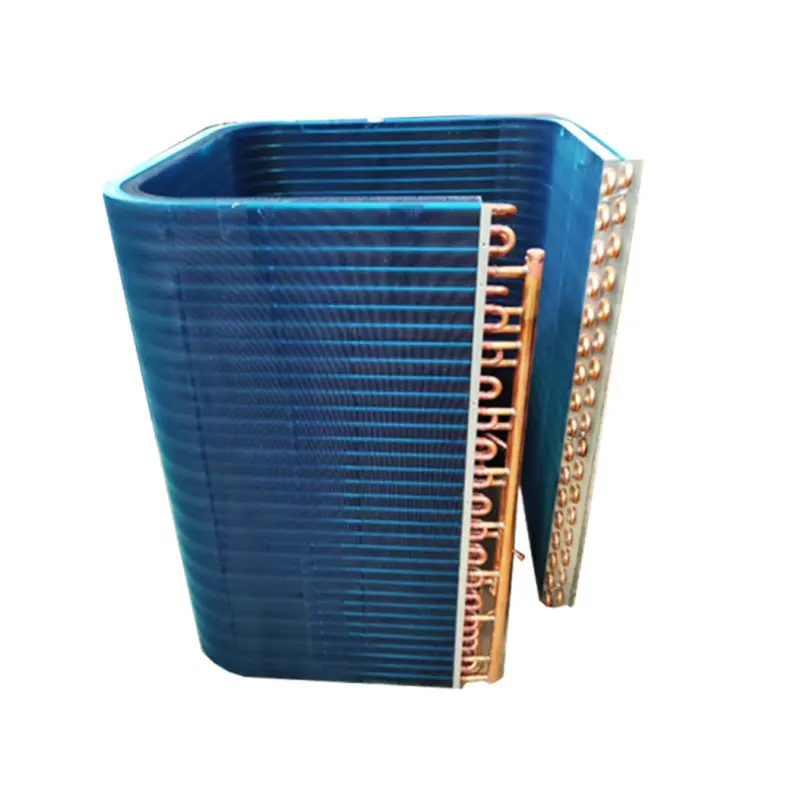

Ningbo Senjun New Materials Co., Ltd., based in China, exemplifies the region's innovation. The company specializes in producing copper aluminum fin heat exchangers for applications such as refrigerators, freezers, and dehumidifiers, showcasing the industry's versatility and importance in modern life.

Key Takeaways

- China is the top producer, holding 35% of the market. This is due to big investments in HVAC and chemical industries.

- India and Turkey come next, with 21% and 18% shares. Their growing factories and good locations help them succeed.

- The United States and Japan focus on making better products. They use advanced technology for high-quality manufacturing.

- Heat exchangers are needed in HVAC, food processing, and chemical industries.

- Top producers aim to save energy and protect the environment. This supports global efforts to reduce pollution.

Top Countries Producing Copper Tube Aluminum Fin Heat Exchangers

China

Production capacity and market share

China dominates the global market for copper tube aluminum fin heat exchangers, holding a significant 35% share. Its production capacity is unmatched, supported by a vast network of manufacturers and suppliers. Companies like Ningbo Senjun New Materials Co., Ltd. lead the way, producing high-quality heat exchangers for diverse applications. Senjun focuses on products like refrigerators, freezers, and dehumidifiers, showcasing the versatility of these components. The country's ability to scale production efficiently ensures it meets both domestic and international demand.

Key industries driving demand

China's industrial growth fuels the demand for heat exchangers. The HVAC sector, driven by urbanization and rising living standards, remains a primary consumer. Additionally, the chemical and petrochemical industries rely heavily on these components for efficient heat transfer. The food and beverage industry also contributes, requiring precise temperature control in processing and storage.

India

Production capacity and market share

India has emerged as a strong contender in the global market, contributing 21% to the production of copper tube aluminum fin heat exchangers. Its growing manufacturing base and focus on quality have positioned it as a reliable supplier. Indian manufacturers cater to both domestic needs and export markets, ensuring steady growth in production capacity.

Key industries driving demand

Several industries in India drive the demand for these heat exchangers:

- HVAC Industry: Increasing urbanization and climate control needs.

- Food and Beverage Processing: Essential for refrigeration and pasteurization.

- Chemical Processing: Modernization and renewable energy investments.

- Oil and Gas Sector: Used in refining and gas compression under harsh conditions.

Turkey

Production capacity and market share

Turkey holds an 18% market share in global shipments of copper tube aluminum fin heat exchangers. Its strategic location between Europe and Asia makes it a key player in the supply chain. Turkish manufacturers focus on quality and innovation, ensuring their products meet international standards.

Key industries driving demand

Turkey's demand stems from its robust HVAC and industrial sectors. The country's growing construction industry also contributes, requiring efficient cooling and heating systems. Additionally, its expanding petrochemical industry relies on heat exchangers for critical processes.

United States

Production capacity and market share

The United States holds a 17% share in the global production of copper tube aluminum fin heat exchangers. Its manufacturing sector benefits from advanced technologies and a strong focus on quality. American companies prioritize innovation, ensuring their products meet the highest standards for efficiency and durability. This commitment to excellence has positioned the U.S. as a reliable supplier for both domestic and international markets.

Key industries driving demand

The industrial sector in the United States drives significant demand for copper tube aluminum fin heat exchangers. Industries such as power generation, chemical processing, oil and gas, and food and beverage rely on these components for efficient heat transfer. I’ve observed that their versatility makes them indispensable across various applications.

The hospitality industry also contributes to demand. Hotels, garment shops, and food and beverage factories require these heat exchangers for refrigeration and climate control. Manufacturing plants further add to the growing need, emphasizing the importance of these components in maintaining operational efficiency.

Japan

Production capacity and market share

Japan remains a key player in the global market for copper tube aluminum fin heat exchangers. While specific market share data is unavailable, Japan’s reputation for advanced manufacturing technologies speaks volumes. Japanese manufacturers excel in precision engineering, producing high-quality heat exchangers that cater to specialized applications. Their focus on innovation ensures they stay competitive in a rapidly evolving market.

Key industries driving demand

Japan’s demand for copper tube aluminum fin heat exchangers stems from several industries. The HVAC sector leads the way, driven by the country’s commitment to energy efficiency and sustainability. Automotive and aerospace industries also play a crucial role, utilizing these components for cooling systems and thermal management.

- HVAC

- Automotive

- Aerospace

- Food and Beverage Processing

The food and beverage industry further highlights the versatility of these heat exchangers. They are essential for maintaining precise temperature control during processing and storage, ensuring product quality and safety.

Key Companies and Suppliers in Leading Countries

China

Ningbo Senjun New Materials Co., Ltd.

Ningbo Senjun New Materials Co., Ltd. stands out as a leader in China’s heat exchanger industry. I’ve observed that the company focuses on the research, development, and production of copper aluminum fin heat exchangers. Their products cater to a wide range of applications, including refrigerators, freezers, medical ultra-low temperature refrigerators, and dehumidifiers. Senjun’s commitment to innovation ensures they remain at the forefront of the market, meeting the diverse needs of both domestic and international clients.

Innovations and advancements in production

Chinese manufacturers consistently push the boundaries of innovation. Companies like Zhejiang Aosen Machinery Co. Ltd. and Zhejiang SunCo Heat Exchange System Co. Ltd. have made significant contributions. Aosen Machinery, established in 2009, specializes in automotive air conditioners and industrial cooling systems. SunCo Heat Exchange System, based in Shaoxing, focuses on air conditioning and refrigeration applications.

Recent advancements include:

- Golden Fin tubes, which enhance heat transfer efficiency.

- Optimized microchannel condenser systems, reducing pressure drop and improving refrigeration performance.

- Heat pipe heat exchange systems, designed for industries like telecommunications and aerospace.

These innovations highlight China’s dedication to improving efficiency and expanding the capabilities of copper tube aluminum fin heat exchangers.

India

Prominent companies and their contributions

India’s heat exchanger market features several key players. Companies like Voltas Limited and Blue Star Limited have established themselves as leaders. Voltas focuses on HVAC systems and industrial cooling, while Blue Star specializes in refrigeration and air conditioning solutions. These companies contribute significantly to India’s growing reputation as a reliable supplier of high-quality heat exchangers.

Innovations and advancements in production

Indian manufacturers prioritize efficiency and sustainability. They have introduced advanced brazing techniques to improve the durability of copper tube aluminum fin heat exchangers. Additionally, they focus on reducing energy consumption in HVAC systems. These advancements align with global trends toward energy efficiency and environmental responsibility.

Turkey

Prominent companies and their contributions

Turkey’s strategic location and robust manufacturing sector make it a key player in the global heat exchanger market. Leading companies include:

| Company Name | Key Focus Areas | Notable Attributes |

|---|---|---|

| Alfa Laval AB | Power generation, chemical processing, HVAC | Innovation, sustainability, energy efficiency |

| Kelvion Holdings GmbH | Power generation, oil and gas, chemical processing | Customer-centric solutions, technological advancements |

| Danfoss A/S | HVAC, power generation, chemical processing | Innovative heat transfer solutions, sustainability |

These companies emphasize quality and innovation, ensuring their products meet international standards.

Innovations and advancements in production

Turkish manufacturers invest heavily in research and development. They focus on enhancing the performance of heat exchangers through advanced materials and design techniques. This commitment to innovation positions Turkey as a reliable supplier for global markets.

United States

Prominent companies and their contributions

The United States boasts a strong presence in the copper tube aluminum fin heat exchanger market, with several companies leading the charge. I’ve observed that firms like Trane Technologies, Carrier Corporation, and Modine Manufacturing Company dominate the industry. Trane Technologies focuses on energy-efficient HVAC systems, offering solutions that cater to both residential and industrial needs. Carrier Corporation, a pioneer in air conditioning, continues to innovate in heat exchanger technology. Modine Manufacturing Company specializes in thermal management solutions, providing products for automotive, HVAC, and industrial applications.

These companies prioritize quality and reliability, ensuring their products meet the highest standards. Their contributions extend beyond domestic markets, as they actively export to meet global demand. This commitment to excellence solidifies the United States' position as a key player in the industry.

Innovations and advancements in production

American manufacturers consistently push the boundaries of innovation. I’ve noticed that they focus on enhancing energy efficiency and reducing environmental impact. For instance, advancements in microchannel heat exchanger technology have improved heat transfer performance while minimizing material usage. Companies also invest in smart manufacturing techniques, such as automation and data analytics, to optimize production processes.

The integration of sustainable practices stands out as a significant trend. Many manufacturers now use eco-friendly refrigerants and recyclable materials in their products. These efforts align with global sustainability goals and reflect the industry's forward-thinking approach. By embracing innovation, the United States continues to set benchmarks for quality and efficiency in the heat exchanger market.

Japan

Prominent companies and their contributions

Japan’s reputation for precision engineering extends to its copper tube aluminum fin heat exchanger industry. I’ve found that the market includes a mix of leading international and domestic companies that drive competition and innovation. Key players include Mitsubishi Electric Corporation, Daikin Industries, and Hitachi Cooling & Heating. Mitsubishi Electric focuses on advanced HVAC systems, offering solutions that emphasize energy efficiency. Daikin Industries, a global leader in air conditioning, integrates cutting-edge technology into its heat exchangers. Hitachi Cooling & Heating provides high-performance products tailored to industrial and commercial applications.

These companies excel in producing high-quality heat exchangers for specialized uses. Their commitment to research and development ensures they remain at the forefront of technological advancements. This dedication to excellence reinforces Japan’s position as a global leader in the industry.

Innovations and advancements in production

Japanese manufacturers prioritize innovation, often setting trends that others follow. I’ve observed that they focus on developing compact and lightweight designs without compromising performance. For example, advancements in fin and tube geometry have enhanced heat transfer efficiency. Manufacturers also invest in automation to improve precision and reduce production costs.

Sustainability plays a crucial role in Japan’s approach to production. Many companies adopt eco-friendly practices, such as using low-GWP refrigerants and optimizing energy consumption during manufacturing. These efforts reflect Japan’s commitment to environmental responsibility and technological leadership. By continuously innovating, Japanese manufacturers maintain their competitive edge in the global market.

Global Significance of Leading Producers

Contribution to the global heat exchanger market

Leading producers of copper tube aluminum fin heat exchangers play a critical role in shaping the global market. Their contributions extend beyond production volume to include significant revenue generation and market share. I’ve observed that companies like Ningbo Senjun New Materials Co., Ltd. and others drive innovation and meet diverse industrial needs.

Here’s a look at some of the key players dominating the heat exchanger market:

| Key Players in the Heat Exchanger Market |

|---|

| Accessen Group |

| Alfa Laval |

| API Heat Transfer |

| Chart Industries |

| Danfoss A/S |

| Hisaka Works. Ltd |

| Exchanger Industries Limited |

| Koch Industries, Inc |

| Thermofin Gmbh |

| Xylem |

These companies ensure a steady supply of high-quality products to meet global demand. Their efforts contribute to the growth of industries like HVAC, chemical processing, and food and beverage.

Role in driving innovation and sustainability

Producers of heat exchangers, including Senjun, lead the way in innovation and sustainability. I’ve noticed that their advancements focus on improving energy efficiency and reducing environmental impact.

- Energy Efficiency: New technologies enhance thermal performance and minimize energy consumption.

- Environmental Sustainability: Improved materials and designs lower greenhouse gas emissions, aligning with global sustainability goals.

- Adaptability to New Technologies: Heat exchangers now support renewable energy systems, ensuring efficient temperature management.

These innovations not only improve product performance but also address the growing need for sustainable solutions. Companies like Senjun exemplify this by producing energy-efficient components for refrigerators, freezers, and dehumidifiers.

Meeting worldwide demand for HVAC and industrial applications

The global demand for HVAC and industrial applications continues to rise. Leading producers meet this demand by offering reliable and efficient solutions. I’ve seen how companies like Senjun cater to diverse industries, from medical refrigeration to industrial cooling.

Their products ensure optimal performance in critical applications. For example, copper tube aluminum fin heat exchangers are essential for maintaining precise temperature control in HVAC systems. This versatility makes them indispensable across sectors like construction, petrochemicals, and food processing.

By addressing these needs, leading producers solidify their position as key contributors to the global market. Their commitment to quality and innovation ensures they remain at the forefront of the industry.

The contributions of China, India, Turkey, the United States, and Japan to the copper tube aluminum fin heat exchanger market are undeniable. Each country plays a pivotal role in shaping the industry.

- China leads with a 35% market share, driven by its vast production capacity and strong export performance.

- India follows with 21%, leveraging its growing manufacturing base and investments in HVAC and chemical sectors.

- Turkey, with its strategic location, continues to expand its role in the global supply chain.

- The United States and Japan excel in innovation, producing high-quality heat exchangers for specialized applications.

These nations collectively meet the rising global demand for copper tube aluminum fin heat exchangers. Their advancements in energy efficiency and sustainability align with global decarbonization efforts. Companies like Ningbo Senjun New Materials Co., Ltd. exemplify this progress by offering innovative solutions for diverse applications, from refrigerators to medical refrigeration systems.

The global heat exchanger market thrives on the contributions of these leading producers. Their commitment to innovation ensures operational efficiency across industries, from HVAC to power generation.

FAQ

What are copper tube aluminum fin heat exchangers used for?

Copper tube aluminum fin heat exchangers transfer heat efficiently in HVAC systems, refrigeration, and industrial cooling. I’ve seen them used in refrigerators, freezers, and dehumidifiers. Companies like Ningbo Senjun New Materials Co., Ltd. produce these components for diverse applications, including medical refrigeration and display cabinets.

Why is China a leader in heat exchanger production?

China dominates due to its vast manufacturing capacity and advanced technology. Companies like Ningbo Senjun New Materials Co., Ltd. drive innovation by producing high-quality heat exchangers for global markets. Their focus on research and development ensures they meet the growing demand across industries like HVAC and petrochemicals.

How do heat exchangers contribute to sustainability?

Heat exchangers improve energy efficiency by optimizing heat transfer. I’ve noticed that manufacturers, including Senjun, adopt eco-friendly practices like using recyclable materials and low-GWP refrigerants. These efforts align with global sustainability goals, reducing environmental impact while maintaining high performance.

What industries benefit most from heat exchangers?

Industries like HVAC, food and beverage, and chemical processing rely heavily on heat exchangers. I’ve observed their importance in refrigeration, pasteurization, and industrial cooling. Companies such as Senjun cater to these sectors by offering versatile solutions for precise temperature control and energy efficiency.

What sets Ningbo Senjun New Materials Co., Ltd. apart?

Senjun excels in producing copper aluminum fin heat exchangers for various applications, including ice makers and ultra-low temperature refrigerators. Their commitment to innovation and quality ensures they meet international standards. I’ve found their focus on research and development keeps them ahead in the competitive market.