Improving Cooling Efficiency with Copper Fin Heat Exchangers Made Easy

Improving cooling efficiency starts with the right technology. Copper fin heat exchangers leverage copper's superior thermal conductivity to optimize heat transfer. These designs enhance airflow and cooling performance. For example, copper fins can boost efficiency by up to 20% when combined with advanced systems. Senjun’s Household Air Conditioner Tri-Fold Evaporator demonstrates how innovation transforms cooling into a seamless experience.

Key Takeaways

- Copper fin heat exchangers improve cooling by up to 20%. This happens because copper moves heat better, making cooling faster and saving energy.

- Installing it correctly is very important. Make sure it has good airflow, tight connections, and is flat to avoid problems.

- Taking care of it helps it last longer. Clean the fins, look for leaks, and check the drainage to keep it working well.

Why Cooling Efficiency Matters

The Impact of Poor Cooling

I’ve seen firsthand how poor cooling can disrupt systems and increase costs. When cooling systems fail to perform, they create a ripple effect. Equipment overheats, leading to higher failure rates and reduced efficiency. For instance, as temperatures rise, the failure rate of systems increases significantly. Take a look at this data:

| Temperature (°F) | Increase in Failure Rate (percentage points) |

|---|---|

| 77 | 1.00 |

| 81.5 | 1.36 |

Even a slight temperature increase can cause noticeable damage. This not only shortens the lifespan of equipment but also drives up energy consumption. Poor cooling forces systems to work harder, consuming more power and inflating energy bills. In my experience, addressing these issues early can save significant costs and prevent downtime.

Benefits of Optimized Cooling

Optimized cooling transforms system performance. I’ve observed how advanced cooling strategies reduce energy consumption and extend equipment longevity. For example, technologies like immersion cooling and hybrid systems balance efficiency and performance. Here’s a breakdown of their benefits:

| Cooling Strategy | Impact on Energy Consumption | Impact on System Longevity |

|---|---|---|

| Immersion Cooling | Significantly improves efficiency and reduces operational costs | Extends lifespan of equipment |

| Hybrid Cooling Systems | Balances performance and efficiency, adapts to varying power densities | Supports scalability and longevity |

| Advanced Cooling Tech | Reduces energy losses and improves overall efficiency | Enhances temperature regulation and equipment lifespan |

Using a Copper Fin Heat Exchanger is one way to achieve optimized cooling. Its superior thermal conductivity ensures efficient heat transfer, reducing the strain on systems. I’ve found that these solutions not only improve cooling but also create a more sustainable and cost-effective operation.

How Copper Fin Heat Exchangers Work

The Science Behind Copper Fins

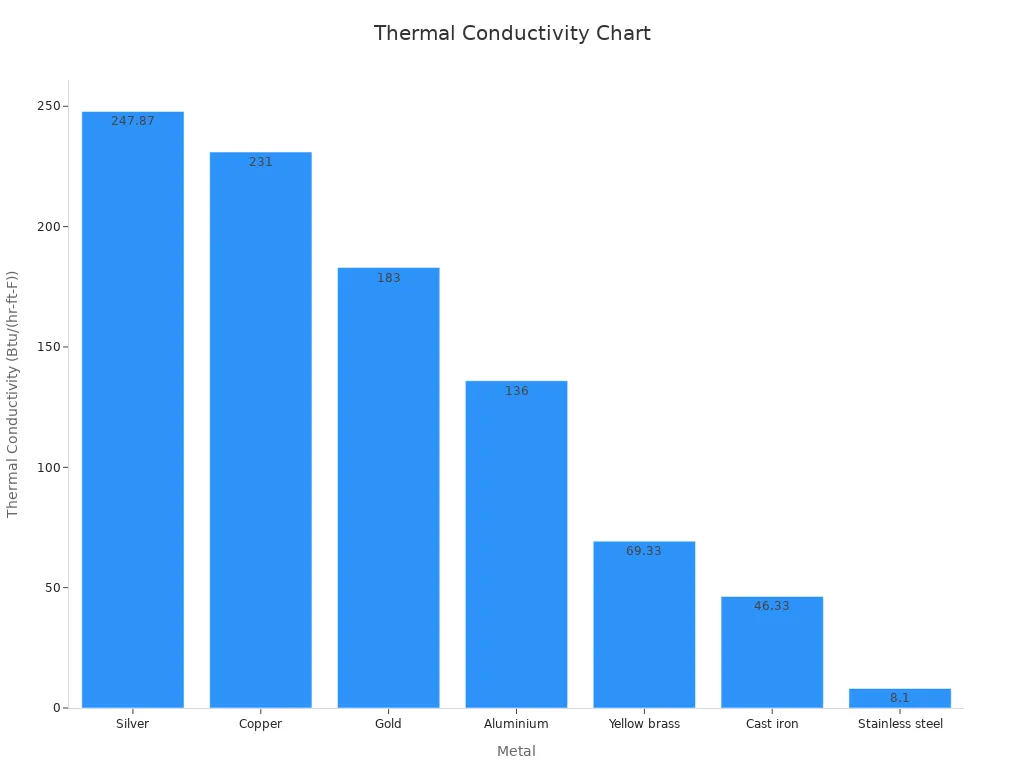

I’ve always been fascinated by the science behind copper’s exceptional thermal conductivity. Copper ranks among the top materials for heat transfer, second only to silver. Its ability to conduct heat efficiently makes it a cornerstone of modern cooling systems. To illustrate this, here’s a comparison of thermal conductivity values for various metals:

| Metal | Thermal conductivity (Btu/(hr-ft-F)) |

|---|---|

| Silver | 247.87 |

| Copper | 231 |

| Gold | 183 |

| Aluminum | 136 |

| Yellow brass | 69.33 |

| Cast iron | 46.33 |

| Stainless steel | 8.1 |

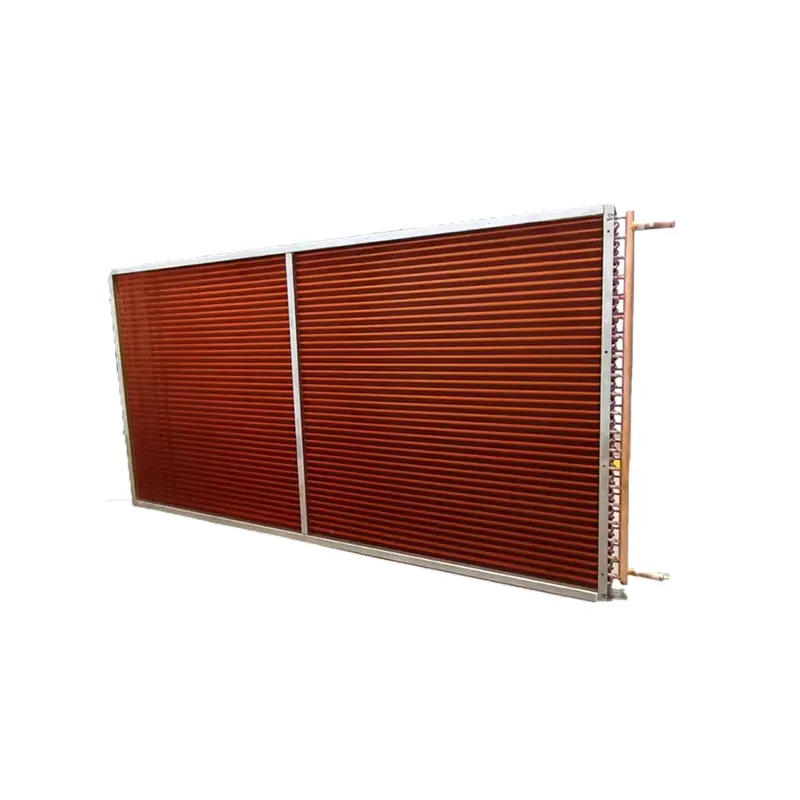

Copper’s high thermal conductivity ensures rapid heat absorption and dissipation. In a Copper Fin Heat Exchanger, this property allows the refrigerant to absorb indoor heat efficiently. The fins, designed to maximize surface area, further enhance this process. By increasing the contact area between the air and the copper, these fins accelerate heat transfer. This results in faster cooling and improved energy efficiency.

The unique design of copper fins also plays a critical role. Smooth sine wave patterns and precise fin spacing, like the 2.5mm spacing in Senjun’s Household Air Conditioner Tri-Fold Evaporator, optimize airflow. This ensures that heat exchange occurs uniformly, preventing hotspots and maintaining consistent cooling performance.

Comparison with Other Materials

When comparing copper to alternative materials, its advantages become even more apparent. I’ve worked with various heat exchanger designs, and copper consistently outperforms other options in terms of efficiency and durability. Here’s a breakdown of how copper stacks up against other materials:

| Material Type | Performance Metrics | Conclusion |

|---|---|---|

| Copper Foams | Enhanced thermal conductivity | Preferred in applications where corrosion is not an issue. |

| Expanded Graphite | Moderate thermal performance | Less effective compared to metallic foams in certain conditions. |

| Metallic Salts in Foams | Investigated for adsorption and desorption | Show potential for heat pump applications but require further study. |

Copper’s superior thermal conductivity gives it a clear edge over materials like aluminum and stainless steel. While aluminum is lighter and less expensive, it falls short in heat transfer efficiency. Stainless steel, on the other hand, offers excellent corrosion resistance but lacks the thermal performance needed for high-efficiency cooling systems.

In my experience, copper’s durability also sets it apart. It resists wear and tear, ensuring long-term performance. This makes it an ideal choice for environments where reliability is crucial. For example, in humid coastal areas, copper fins maintain their efficiency even under challenging conditions. This resilience, combined with their unmatched thermal properties, makes Copper Fin Heat Exchangers a preferred solution for optimized cooling.

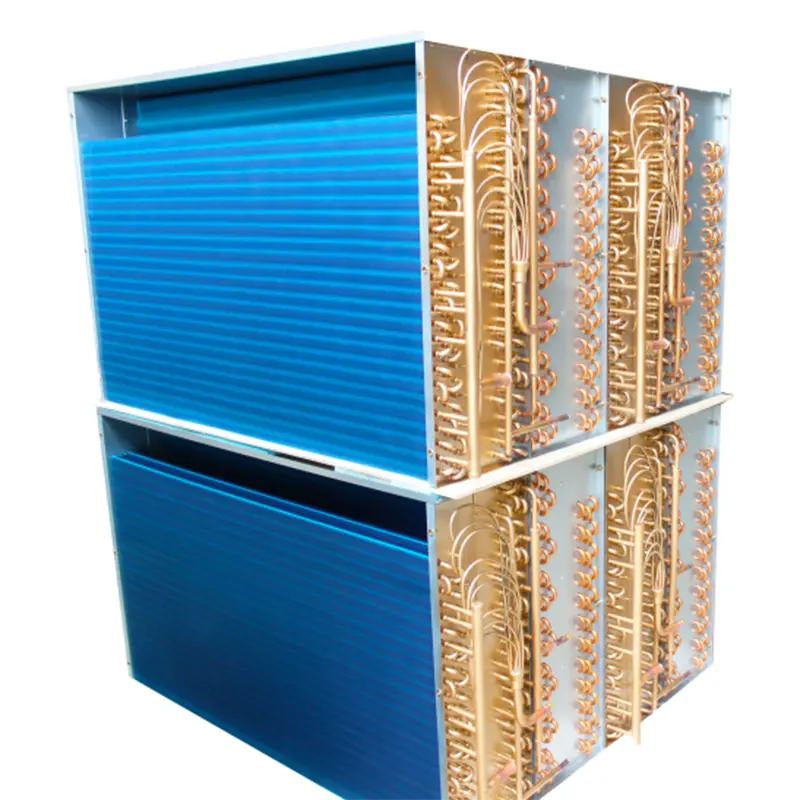

Features of the Household Air Conditioner Tri-Fold Evaporator

Unique Three-Layer Folded Fin Design

The three-layer folded fin design stands out as a game-changer in cooling technology. I’ve seen how this innovative structure increases the heat exchange area by 50%, allowing for faster and more efficient cooling. The fins, crafted with precision, maximize surface contact between air and copper, ensuring rapid heat dissipation. This design not only enhances cooling performance but also reduces energy consumption. For example, in a 15m² room, the evaporator can lower the temperature from 32°C to 26°C in just eight minutes. Such efficiency makes it an ideal choice for compact spaces and urban living.

Anti-Dust Coating and Drainage System

The anti-dust coating on the fins is another feature that I find remarkable. It prevents dust accumulation, ensuring consistent airflow and maintaining optimal performance over time. The integrated drainage system complements this by effectively managing condensation. In high-pressure environments, the system reduces water pressure by 60%, achieving a maximum pressure of 0.6 MPa. This improvement minimizes the risk of leaks and ensures hassle-free operation. Together, these features enhance the durability and reliability of the evaporator, even in challenging conditions like humid coastal areas.

Compatibility with Inverter Systems

The compatibility with inverter systems further elevates the evaporator’s appeal. I’ve noticed how this feature reduces energy consumption by up to 20% while maintaining low noise levels below 25dB. This makes it perfect for quiet environments like bedrooms or offices. The inverter compatibility also ensures smooth temperature regulation, providing a comfortable and energy-efficient cooling experience.

Steps to Maximize Cooling Efficiency with Copper Fin Heat Exchangers

Proper Installation

Proper installation is the foundation of an efficient cooling system. I’ve observed that even the most advanced Copper Fin Heat Exchanger can underperform if installed incorrectly. To ensure optimal performance, it’s essential to follow these steps:

- Choose the Right Location: Install the unit in a well-ventilated area, away from direct sunlight or obstructions. This prevents overheating and ensures consistent airflow.

- Secure Connections: Ensure all copper tube connections are tight and leak-free. Loose connections can lead to refrigerant loss, reducing cooling efficiency.

- Level the Unit: A level installation prevents uneven drainage and ensures the system operates smoothly.

I always recommend consulting a professional technician for installation. Their expertise minimizes errors and ensures the system operates at peak efficiency from day one.

Tip: Use a spirit level during installation to avoid alignment issues that could affect drainage and airflow.

Regular Maintenance

Regular maintenance is crucial for extending the lifespan of your cooling system. I’ve seen how neglecting upkeep can lead to reduced efficiency and costly repairs. Here’s a comparison of how maintenance impacts the average lifespan of cooling systems:

| Maintenance Level | Average Lifespan (Years) |

|---|---|

| Regular Maintenance | 20 - 25 |

| Lack of Maintenance | 15 - 18 |

| ASHRAE Estimate | 15 - 25 |

To keep your Copper Fin Heat Exchanger in top condition, follow these maintenance practices:

- Clean the Fins: Dust and debris can accumulate on the fins, reducing airflow. Use a soft brush or vacuum to clean them regularly.

- Inspect for Leaks: Check the copper tubes and connections for signs of refrigerant leaks. Addressing leaks promptly prevents performance issues.

- Test the Drainage System: Ensure the integrated drainage system is free from blockages. This prevents water buildup and potential damage.

Scheduling annual professional inspections can also help identify and resolve issues before they escalate.

Note: A well-maintained system not only lasts longer but also operates more efficiently, saving energy and reducing costs.

System Optimization Tips

Optimizing your cooling system goes beyond installation and maintenance. I’ve found that small adjustments can significantly enhance performance. Here are some tips to maximize the efficiency of your Copper Fin Heat Exchanger:

- Use Inverter-Compatible Systems: Pairing the heat exchanger with an inverter system reduces energy consumption by up to 20%. This combination ensures smooth temperature regulation and quieter operation.

- Set Optimal Temperatures: Avoid setting the thermostat too low. Maintaining a temperature between 24°C and 26°C balances comfort and energy efficiency.

- Enhance Airflow: Keep the area around the unit clear of obstructions. Improved airflow allows the heat exchanger to dissipate heat more effectively.

- Monitor Humidity Levels: In humid environments, use the dehumidification mode to maintain indoor comfort. This feature is particularly useful in coastal areas.

By implementing these strategies, you can achieve a cooling system that is both efficient and reliable.

Pro Tip: Regularly update your system’s firmware if applicable. Manufacturers often release updates to improve performance and energy efficiency.

Copper fin heat exchangers, like the Household Air Conditioner Tri-Fold Evaporator, deliver unmatched cooling efficiency. I’ve seen how features such as the three-layer folded fin design and anti-dust coating enhance performance and durability. Simple steps, including proper installation and regular maintenance, can maximize results. Explore Senjun’s innovative solutions to transform your indoor comfort today.

FAQ

What makes copper fins better than aluminum fins for heat exchangers?

Copper fins excel due to their superior thermal conductivity. They transfer heat more efficiently, ensuring faster cooling and better energy savings compared to aluminum fins.

Tip: Copper fins also resist wear and tear, making them ideal for long-term use in challenging environments.

How does the anti-dust coating improve performance?

The anti-dust coating prevents debris buildup on the fins. This ensures consistent airflow, maintains cooling efficiency, and reduces the need for frequent cleaning.

Can the Household Air Conditioner Tri-Fold Evaporator work in humid climates?

Yes, it performs exceptionally well in humid areas. Its advanced dehumidification system removes up to 1.5 liters of water per hour, ensuring a comfortable indoor environment.

Note: This feature is particularly beneficial in coastal cities with high humidity levels.