How to Select the Best Wire Tube Condenser for Your Cooling Needs

Choosing the right wire tube condenser plays a vital role in achieving efficient cooling. It ensures optimal heat transfer from refrigerants to air, thanks to its large surface area. This efficiency depends on factors like airflow, coil design, and ambient temperature. A well-chosen condenser enhances cooling capacity, reduces energy consumption, and boosts durability. High-quality materials also guarantee long-term reliability and lower maintenance costs.

Ningbo Senjun New Materials Co., Ltd. specializes in producing wire tube condensers and copper aluminum fin heat exchangers. Their products serve various applications, including refrigerators, freezers, medical ultra-low temperature refrigerators, and more. Their expertise ensures reliable and energy-efficient solutions for your cooling needs.

Key Takeaways

- Picking the right wire tube condenser helps save energy and cool better.

- Look at the size to make sure it fits your system.

- Good materials like copper and steel last long and cool well.

- Match the cooling power to your system's heat needs.

- Make sure the condenser works with your refrigerant to avoid problems.

- Keep the area around the condenser clear for better cooling.

- Clean the coils and check for rust to keep it working well.

- Ask manufacturers for advice to choose the best condenser for you.

What Is a Wire Tube Condenser?

Definition and Overview

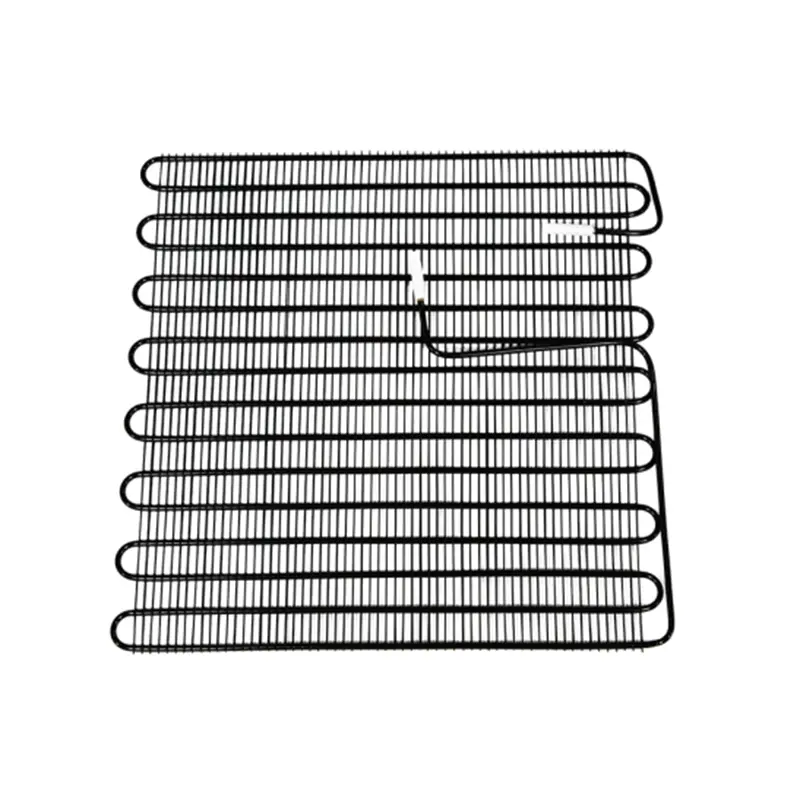

When I think about cooling systems, the wire tube condenser stands out as a key component. It’s essentially a heat exchanger made up of copper or steel tubes arranged in a coil or serpentine pattern. These tubes are supported by steel wires, which add stability and improve heat dissipation. The design is simple yet highly effective. Refrigerant flows through the tubes, releasing heat it has absorbed from inside the cooling system to the surrounding air. This process ensures the refrigerant transitions from a vapor back into a liquid, completing the cooling cycle.

The fins on the tubes increase the surface area, which makes heat transfer more efficient. Materials like copper, aluminum, and steel are commonly used in its construction. Each material is chosen for its specific properties, such as durability or thermal conductivity. This combination of design and materials ensures the wire tube condenser performs reliably in various cooling applications.

How Wire Tube Condensers Work

Let me explain how a wire tube condenser operates. Imagine a refrigerator or air conditioner. Inside, the refrigerant absorbs heat from the space it’s cooling. This heat needs to go somewhere, and that’s where the wire tube condenser comes in. The refrigerant flows through the condenser’s tubes, which are exposed to air. As the refrigerant moves, it releases the absorbed heat into the air around the tubes.

The steel wires supporting the tubes play an important role here. They increase the surface area for heat exchange, allowing the condenser to work more efficiently. The process is continuous, ensuring the refrigerant cools down and returns to its liquid state. This cycle keeps your cooling system running smoothly.

Common Applications in Cooling Systems

Wire tube condensers are incredibly versatile. I’ve seen them used in a wide range of cooling systems. For example:

- Refrigeration units like commercial freezers and chillers

- Air conditioning systems in HVAC setups

- Walk-in freezers and beverage coolers

- Medical ultra-low temperature refrigerators

They’re also found in larger industrial settings, such as power plants and chemical processing facilities. Ningbo Senjun New Materials Co., Ltd. specializes in producing wire tube condensers for these applications. Their products are designed to meet the demands of refrigerators, freezers, drinking fountains, display cabinets, wine cabinets, ice makers, and more. This versatility makes wire tube condensers a popular choice for both commercial and industrial cooling systems.

Key Factors to Consider When Choosing a Wire Tube Condenser

Size and Dimensions

When selecting a wire tube condenser, size and dimensions play a critical role. I always consider how the condenser's design impacts its performance. The arrangement of copper tubes and steel wires increases the surface area, which improves heat exchange. The open structure also allows better airflow, which is essential for effective cooling.

Here’s why size matters:

- Larger condensers with more tubes can transfer heat faster, making them ideal for high-capacity cooling systems.

- Compact designs work well in smaller appliances, like wine cabinets or dehumidifiers, where space is limited.

- Proper sizing ensures the condenser fits seamlessly into the cooling system without compromising efficiency.

Ningbo Senjun New Materials Co., Ltd. offers a variety of sizes to meet different cooling needs. Their expertise ensures that each condenser is optimized for maximum performance.

Material and Build Quality

The materials used in a wire tube condenser determine its durability and efficiency. I’ve noticed that copper and steel are the most common choices, each offering unique advantages.

- Steel Tube Condensers: These are highly durable and resist corrosion, making them perfect for commercial and industrial applications. They also handle high temperatures well.

- Copper Tube Condensers: Copper’s excellent thermal conductivity ensures quick heat transfer. It’s also durable and flexible, allowing for customized designs.

Here’s a quick comparison:

| Material | Durability Characteristics |

|---|---|

| Steel | Highly resistant to corrosion and can withstand high temperatures. |

| Copper | Excellent heat conductor but more susceptible to corrosion if not maintained properly. |

The combination of copper and steel in many condensers provides long-lasting reliability. Ningbo Senjun New Materials Co., Ltd. uses high-quality materials to ensure their products perform well in demanding environments.

Cooling Capacity and Performance

Cooling capacity is another key factor I evaluate. A wire tube condenser must handle the heat load of the system it supports. The size and arrangement of the tubes directly affect how efficiently heat transfers from the refrigerant to the surrounding air.

Proper ventilation also plays a big role. Without adequate airflow, the condenser struggles to release heat, which increases energy consumption. I always ensure the installation site has good ventilation to enhance cooling efficiency and prevent overheating.

Ningbo Senjun New Materials Co., Ltd. designs their condensers with performance in mind. Their products reduce refrigerant usage and improve energy efficiency, contributing to sustainable refrigeration practices. This makes them a reliable choice for both residential and commercial cooling systems.

Compatibility with Refrigerant Type

When I choose a wire tube condenser, I always check its compatibility with the refrigerant type. Refrigerants play a critical role in cooling systems. Each type has unique chemical properties that affect how the condenser performs. Using the wrong condenser with an incompatible refrigerant can lead to inefficiency or even system failure.

For example, some condensers work best with traditional refrigerants like R-134a, while others are designed for newer, eco-friendly options like R-600a or R-290. I’ve noticed that refrigerants with lower global warming potential (GWP) are becoming more popular due to environmental regulations. These refrigerants require condensers that can handle their specific pressure and thermal characteristics.

I also consider the operating pressure of the refrigerant. High-pressure refrigerants need condensers built with durable materials like steel or copper. This ensures the system remains safe and efficient. Ningbo Senjun New Materials Co., Ltd. offers wire tube condensers compatible with a wide range of refrigerants. Their expertise helps me find the right match for my cooling needs.

Environmental Considerations and Ventilation Needs

Environmental factors significantly influence the performance of a wire tube condenser. I always evaluate the installation site to ensure proper ventilation. Without adequate airflow, the condenser struggles to release heat, which reduces its efficiency. Poor ventilation can also cause the system to overheat, leading to higher energy consumption and potential damage.

I recommend placing the condenser in a location with good air circulation. Avoiding enclosed spaces or areas with high ambient temperatures is essential. For instance, I’ve seen how condensers installed near walls or other obstructions often perform poorly. The open design of a wire tube condenser allows for better airflow, but it still needs a well-ventilated environment to function optimally.

Environmental sustainability is another factor I consider. Many modern cooling systems aim to reduce their carbon footprint. Choosing a condenser that supports eco-friendly refrigerants and operates efficiently aligns with these goals. Ningbo Senjun New Materials Co., Ltd. designs their condensers with energy efficiency in mind. Their products help reduce refrigerant usage and minimize environmental impact, making them a reliable choice for sustainable cooling solutions.

Benefits of Wire Tube Condensers

Energy Efficiency and Space Optimization

When I think about cooling systems, energy efficiency always comes to mind. A wire tube condenser excels in this area. Its design ensures efficient heat transfer, which reduces the workload on the cooling system. This means the system consumes less electricity, leading to lower energy bills over time. I’ve noticed that the open structure of the condenser enhances airflow around the tubes. This improves heat dissipation and keeps the system running smoothly. Copper tubes absorb heat quickly, while steel wires help release it into the air. This combination maintains stable temperatures and prevents energy waste.

Space optimization is another advantage. The compact design of a wire tube condenser makes it ideal for appliances like refrigerators and freezers. It fits seamlessly into systems without taking up unnecessary space. Ningbo Senjun New Materials Co., Ltd. offers condensers that balance energy efficiency and space-saving features. Their products ensure reliable performance while minimizing environmental impact.

Durability and Longevity

Durability is a key factor I consider when choosing a condenser. Wire tube condensers stand out because they’re made from robust materials like copper and steel. These materials resist wear and tear better than the thinner materials used in other types of condensers. For example, plate condensers may not last as long due to their susceptibility to damage. The open design of a wire tube condenser also makes it easier to clean and maintain, which enhances its reliability over time.

I’ve seen how finned condensers can suffer from bent or broken fins, which compromise their performance. In contrast, wire tube condensers maintain their efficiency even in demanding environments. Ningbo Senjun New Materials Co., Ltd. uses high-quality materials to ensure their products deliver long-term reliability. Their condensers are built to withstand the challenges of both residential and commercial applications.

Low Maintenance Requirements

One of the things I appreciate most about wire tube condensers is their low maintenance needs. Regular upkeep is simple and straightforward. I recommend conducting visual inspections to check for structural integrity and corrosion. Cleaning the coils regularly enhances heat transfer and prevents scale build-up. Keeping the area around the condenser clear ensures proper airflow, which is essential for efficient operation.

I also advise inspecting fan assemblies for cracks and listening for unusual noises. Checking electrical connections and mechanical components like shafts and bearings helps prevent potential issues. These practices require minimal effort but go a long way in maintaining the condenser’s performance. The open design of a wire tube condenser makes these tasks even easier. With products from Ningbo Senjun New Materials Co., Ltd., I’ve found that maintenance is rarely a hassle. Their condensers are designed for durability and ease of use, making them a cost-effective choice in the long run.

Cost-Effectiveness Over Time

When I evaluate cooling systems, cost-effectiveness always stands out as a critical factor. A wire tube condenser offers significant savings over time, making it an excellent investment for both residential and commercial applications. Its design ensures efficient heat transfer, which reduces energy consumption. Lower energy bills quickly offset the initial cost of the condenser.

Durability also plays a key role in long-term savings. Wire tube condensers, made from robust materials like copper and steel, resist wear and tear. This durability minimizes the need for frequent replacements. I’ve seen how systems with high-quality condensers, such as those from Ningbo Senjun New Materials Co., Ltd., last for years without major issues. Their products are built to handle demanding environments, ensuring reliability and reducing maintenance costs.

Maintenance is another area where these condensers shine. The open design makes cleaning and inspections straightforward. Regular upkeep, like clearing debris and checking for corrosion, keeps the system running efficiently. These simple tasks prevent costly repairs and extend the lifespan of the condenser. I always recommend scheduling routine maintenance to maximize cost-effectiveness.

Energy efficiency further enhances savings. A wire tube condenser operates with minimal energy waste, thanks to its optimized design. By reducing the workload on the cooling system, it lowers electricity usage. Over time, this efficiency translates into substantial financial benefits. For businesses, these savings can significantly impact operational costs.

I also consider the environmental benefits. Many modern wire tube condensers, including those from Ningbo Senjun New Materials Co., Ltd., support eco-friendly refrigerants. These systems align with sustainability goals while maintaining high performance. Choosing an energy-efficient condenser not only saves money but also reduces the carbon footprint of the cooling system.

In my experience, investing in a high-quality wire tube condenser pays off in the long run. The combination of durability, low maintenance, and energy efficiency ensures consistent performance and cost savings. Ningbo Senjun New Materials Co., Ltd. specializes in designing condensers that deliver these benefits. Their expertise makes them a trusted choice for reliable and cost-effective cooling solutions.

Comparing Wire Tube Condensers to Other Types

Wire Tube vs. Plate Condensers

When I compare wire tube condensers to plate condensers, the differences in performance and design stand out. Wire tube condensers use a serpentine coil design, which increases the heat exchange area. This design improves heat dissipation and reduces energy consumption. Plate condensers, on the other hand, rely on thin, flat plates for heat transfer. While compact, they often require more frequent cleaning to maintain efficiency.

Here’s a quick comparison:

| Feature | Wire Tube Condenser | Plate Condenser |

|---|---|---|

| Airflow | Open structure allows better airflow | Narrow spaces can clog with debris |

| Cooling Efficiency | More effective due to improved heat dissipation | Requires frequent cleaning |

| Maintenance | Easier to clean due to open design | More time-consuming to maintain |

| Durability | More durable with copper and steel | Less durable with thin plates |

In my experience, wire tube condensers excel in durability and ease of maintenance. Their open structure ensures better airflow, which enhances cooling performance. Ningbo Senjun New Materials Co., Ltd. produces high-quality wire tube condensers that deliver reliable and energy-efficient cooling solutions for various applications.

Wire Tube vs. Finned Condensers

Wire tube condensers and finned condensers both serve critical roles in cooling systems, but their designs differ significantly. Wire tube condensers feature a robust, open design that ensures consistent performance over time. This makes them particularly reliable in demanding applications. Finned condensers, while effective, are more prone to damage. Bent or broken fins can hinder performance and require repairs.

I’ve noticed that finned condensers accumulate dust in their narrow spaces, which increases maintenance needs. In contrast, wire tube condensers simplify maintenance tasks with their open structure. This design not only reduces upkeep but also ensures efficient heat transfer. For businesses or households seeking long-term reliability, wire tube condensers often prove to be the better choice.

Pros and Cons of Each Type

Each type of condenser has its strengths and weaknesses. Here’s what I’ve observed:

-

Pros of Wire Tube Condensers:

- Efficient heat dissipation ensures consistent temperature, reducing energy consumption.

- Open design allows better airflow, improving cooling performance and simplifying maintenance.

- Durable construction resists wear and tear, making them reliable for long-term use.

- Low maintenance requirements reduce the risk of system failure, which is crucial for sensitive items like food and medicine.

-

Cons of Wire Tube Condensers:

- May not be as compact as plate condensers, which can save space in certain applications.

- Performance can be less efficient in specific scenarios compared to specialized designs like finned condensers.

Ningbo Senjun New Materials Co., Ltd. specializes in wire tube condensers that maximize these advantages. Their products are designed for durability, energy efficiency, and ease of use, making them a trusted choice for both residential and commercial cooling systems.

How to Select the Best Wire Tube Condenser for Your Needs

Assessing Your Cooling Requirements

When I assess cooling requirements, I focus on several critical factors. These factors help me determine the right wire tube condenser for the job. Here’s a table that summarizes the key considerations:

| Factor | Description |

|---|---|

| Cooling Water Velocity | Influences heat transfer; should be maintained between 5 to 8 fps to balance heat transfer rate and power requirements. |

| Overall Heat Transfer Coefficient | A higher coefficient reduces the size of the condenser needed; depends on cooling water velocity, purity, and temperature. |

| Tube Parameters | Smaller diameter tubes require less surface area and pressure drop, but higher velocities are limited in smaller tubes. |

| Temperature of Cooling Water | Lower temperatures can enhance turbine output and reduce condenser surface area, but may lead to sub-cooling issues. |

| Pressure Drop | Should be kept low (2 to 7 psi) to minimize pumping power requirements. |

I always start by evaluating the cooling system’s heat load. This helps me decide the size and capacity of the condenser. For example, a refrigerator requires a smaller condenser compared to an industrial freezer. I also consider the refrigerant type and operating conditions. These factors ensure the condenser performs efficiently and lasts longer.

Consulting with Experts or Manufacturers (e.g., Ningbo Senjun New Materials Co., Ltd.)

Consulting with experts or manufacturers simplifies the selection process. I often reach out to manufacturers like Ningbo Senjun New Materials Co., Ltd. for guidance. Their expertise in wire tube condensers ensures I get the best solution for my cooling needs. Here’s why consulting them is beneficial:

- They provide condensers tailored for HVAC systems, ensuring efficient cooling and dehumidification.

- Their products maintain optimal temperatures in refrigeration units, which is essential for food preservation.

- They offer solutions for industrial applications, such as power plants and chemical processing facilities, improving energy efficiency.

I’ve found that their condensers excel in energy efficiency. They feature a high heat transfer coefficient, which reduces energy consumption and utility costs. Their robust construction ensures long-lasting performance, making them a reliable choice for both residential and commercial systems. Additionally, their open design promotes better air circulation, leading to quieter operation and reduced maintenance needs.

Evaluating Long-Term Costs and Benefits

When I evaluate long-term costs and benefits, I consider the entire life cycle of the condenser. This includes installation, operation, and maintenance costs. I’ve seen how choosing the right materials can significantly impact operating economics. For example, durable materials like copper and steel require less maintenance, reducing overall costs.

In one case study, a plant assessed the life-cycle economics of its cooling system over 20 years. By controlling water chemistry, they ensured the condenser materials lasted the expected duration without replacement. This approach minimized costs and maximized efficiency. I always recommend conducting a similar analysis to understand the long-term benefits of a wire tube condenser.

Energy efficiency is another critical factor. A high-quality condenser reduces energy consumption, leading to lower utility bills. Over time, these savings offset the initial investment. I also consider the environmental benefits. Many modern condensers, including those from Ningbo Senjun New Materials Co., Ltd., support eco-friendly refrigerants. This aligns with sustainability goals while maintaining high performance.

Ensuring Proper Installation and Maintenance

Proper installation and maintenance ensure that a wire tube condenser operates efficiently and lasts longer. I’ve learned that even the best condenser won’t perform well if it’s not installed or maintained correctly. Here are some steps I always follow to get the most out of a condenser.

Installation Tips

-

Choose the Right Location

I always pick a spot with good airflow. Placing the condenser in a well-ventilated area prevents overheating. Avoiding enclosed spaces or areas near walls ensures air can circulate freely around the unit. -

Secure the Condenser Properly

During installation, I make sure the condenser is mounted securely. Loose fittings can cause vibrations, which may lead to damage over time. Using the right tools and brackets ensures the unit stays stable. -

Check for Compatibility

Before installation, I confirm that the condenser matches the cooling system’s refrigerant type and capacity. This step prevents performance issues and ensures the system runs smoothly. Ningbo Senjun New Materials Co., Ltd. offers condensers designed for various refrigerants, making it easier to find the right fit. -

Inspect Connections

I always double-check the connections between the condenser and the cooling system. Tight seals prevent refrigerant leaks, which can harm both the environment and the system’s efficiency.

Maintenance Best Practices

-

Clean the Coils Regularly

Dust and debris can build up on the condenser’s coils, reducing its ability to release heat. I recommend cleaning the coils every few months. A soft brush or vacuum works well for this task. -

Inspect for Corrosion

Over time, exposure to moisture can cause rust or corrosion. I look for signs of wear during routine inspections. Using high-quality materials, like those in Ningbo Senjun New Materials Co., Ltd.’s products, reduces the risk of corrosion. -

Check Airflow

Blocked airflow can overwork the condenser. I keep the area around the unit clear of obstructions like leaves or debris. This simple step improves efficiency and prevents overheating. -

Schedule Professional Servicing

While regular maintenance is easy to handle, I also recommend scheduling professional servicing once a year. Experts can identify potential issues early and ensure the system stays in top condition.

Ningbo Senjun New Materials Co., Ltd. specializes in durable and efficient wire tube condensers. Their products require minimal maintenance, making them a reliable choice for refrigerators, freezers, and other cooling systems. By following these installation and maintenance tips, I’ve seen how a condenser can deliver consistent performance for years.

Common Mistakes to Avoid When Choosing a Wire Tube Condenser

Overlooking System Compatibility

I’ve seen many people overlook system compatibility when selecting a wire tube condenser. This mistake can lead to inefficiency or even system failure. Every cooling system has unique requirements, and the condenser must align with those needs. For example, the refrigerant type plays a critical role. Some condensers work best with traditional refrigerants like R-134a, while others are designed for eco-friendly options like R-600a or R-290. Using an incompatible condenser can reduce performance and increase energy consumption.

The operating conditions also matter. High-pressure systems need condensers made from durable materials like steel or copper. These materials handle the stress of high pressure without compromising efficiency. I always recommend consulting with experts or manufacturers, such as Ningbo Senjun New Materials Co., Ltd., to ensure compatibility. Their expertise helps me find the right condenser for any cooling system, whether it’s a refrigerator, freezer, or medical ultra-low temperature unit.

Ignoring Energy Efficiency Ratings

Energy efficiency is one of the most important factors I consider when choosing a wire tube condenser. Ignoring this aspect can lead to higher energy bills and reduced system performance. Wire tube condensers excel in energy efficiency because they optimize heat transfer. Their heat transfer coefficient is about 50% higher than plate condensers and 10%-15% higher than louver condensers. This means they use less energy to achieve the same cooling effect, which lowers utility costs.

I’ve noticed that energy-efficient condensers also improve long-term reliability. They reduce the workload on the cooling system, preventing wear and tear. This efficiency makes wire tube condensers an excellent choice for various applications, from residential refrigerators to industrial freezers. Ningbo Senjun New Materials Co., Ltd. designs their condensers with energy savings in mind. Their products not only minimize energy costs but also ensure consistent performance over time.

Choosing Based on Price Alone

I’ve learned that choosing a wire tube condenser based solely on price can lead to costly mistakes. While it’s tempting to go for the cheapest option, this approach often results in higher long-term expenses. Here are some risks I’ve observed:

- Cheaper materials may require frequent maintenance, increasing operational costs.

- Poor-quality condensers can lead to performance issues, reducing cooling efficiency.

- In extreme cases, subpar materials can cause system failures, leading to expensive repairs or replacements.

Investing in a high-quality condenser saves money in the long run. Durable materials like copper and steel resist wear and tear, reducing maintenance needs. I’ve found that products from Ningbo Senjun New Materials Co., Ltd. strike the perfect balance between cost and quality. Their condensers deliver reliable performance while minimizing operational expenses. This makes them a smart choice for anyone looking to optimize their cooling system.

💡 Tip: Always evaluate the total cost of ownership, including maintenance and energy expenses, rather than focusing solely on the initial price.

Selecting the right wire tube condenser is essential for achieving efficient and reliable cooling. I always focus on key factors like cooling capacity, energy efficiency, and durability. These elements ensure the condenser meets the demands of your system while minimizing costs. Here’s a quick summary of what to consider:

| Factor | Description |

|---|---|

| Cooling Capacity | Ensure the condenser meets the cooling demands of your application. |

| Energy Efficiency | Look for models that offer high efficiency to reduce energy costs. |

| Durability | Choose condensers made from high-quality materials for long-term reliability. |

| Size and Design | Opt for a compact design if space is a concern. |

| Environmental Impact | Prioritize energy-efficient options to minimize your carbon footprint. |

I also recommend paying attention to details like wall thickness, cooling water velocity, and inlet temperature. These factors directly impact performance and longevity. Ningbo Senjun New Materials Co., Ltd. offers expert guidance and high-quality products tailored to various cooling needs. Their commitment to innovation ensures you’ll find the perfect solution for your system. Take the time to evaluate your requirements and consult with trusted manufacturers to make the best choice.

FAQ

What is the primary purpose of a wire tube condenser?

A wire tube condenser removes heat from the refrigerant in cooling systems. It ensures the refrigerant transitions back to a liquid state, completing the cooling cycle. This process keeps appliances like refrigerators and freezers functioning efficiently.

How do I know which size wire tube condenser to choose?

I always match the condenser size to the cooling system’s capacity. Larger systems need bigger condensers for effective heat transfer. Compact systems, like wine cabinets, require smaller designs. Ningbo Senjun New Materials Co., Ltd. offers various sizes to fit different needs.

Why is material quality important in wire tube condensers?

Material quality affects durability and performance. Copper provides excellent heat transfer, while steel resists corrosion. High-quality materials ensure long-lasting reliability. Ningbo Senjun New Materials Co., Ltd. uses premium materials for their condensers, ensuring top-notch performance.

Can wire tube condensers work with eco-friendly refrigerants?

Yes, many wire tube condensers support eco-friendly refrigerants like R-600a and R-290. I always check compatibility before choosing a condenser. Ningbo Senjun New Materials Co., Ltd. designs their products to work with a wide range of refrigerants, including environmentally friendly options.

How often should I maintain my wire tube condenser?

I recommend cleaning the coils every few months and inspecting for corrosion regularly. Keeping the area around the condenser clear ensures proper airflow. Annual professional servicing also helps maintain efficiency. Products from Ningbo Senjun New Materials Co., Ltd. are designed for easy maintenance.

What makes wire tube condensers energy efficient?

Wire tube condensers optimize heat transfer with their open design and high-quality materials. This reduces the workload on the cooling system, lowering energy consumption. I’ve found that products from Ningbo Senjun New Materials Co., Ltd. excel in energy efficiency.

Are wire tube condensers suitable for industrial applications?

Yes, wire tube condensers work well in industrial settings like power plants and chemical facilities. Their durability and efficiency make them reliable for demanding environments. Ningbo Senjun New Materials Co., Ltd. specializes in condensers for both commercial and industrial uses.

Why should I consult a manufacturer before purchasing?

Manufacturers provide expert guidance on selecting the right condenser. I often consult Ningbo Senjun New Materials Co., Ltd. for tailored solutions. Their expertise ensures I get a product that meets my cooling needs and performs efficiently.