How to Select Reliable Refrigeration Parts Suppliers: 5 Key Metrics

Choosing the right refrigeration parts supplier ensures smooth operations and cost savings. A strategic sourcing approach reduces supply chain risks and improves equipment performance. For instance, sourcing high-quality components like a wire tube condenser minimizes obsolescence risks and lowers total ownership costs. Reliable suppliers help you achieve long-term success through consistent quality and service.

Key Takeaways

- Choose good-quality refrigeration parts for better performance and trust. Good parts lower breakdowns and repair expenses.

- Check if suppliers deliver on time and have a good record. Trustworthy suppliers keep things running without problems.

- Make sure prices are clear to avoid surprise charges. Knowing all costs helps you plan your money well.

Product Quality and Industry Standards

Importance of High-Quality Refrigeration Parts

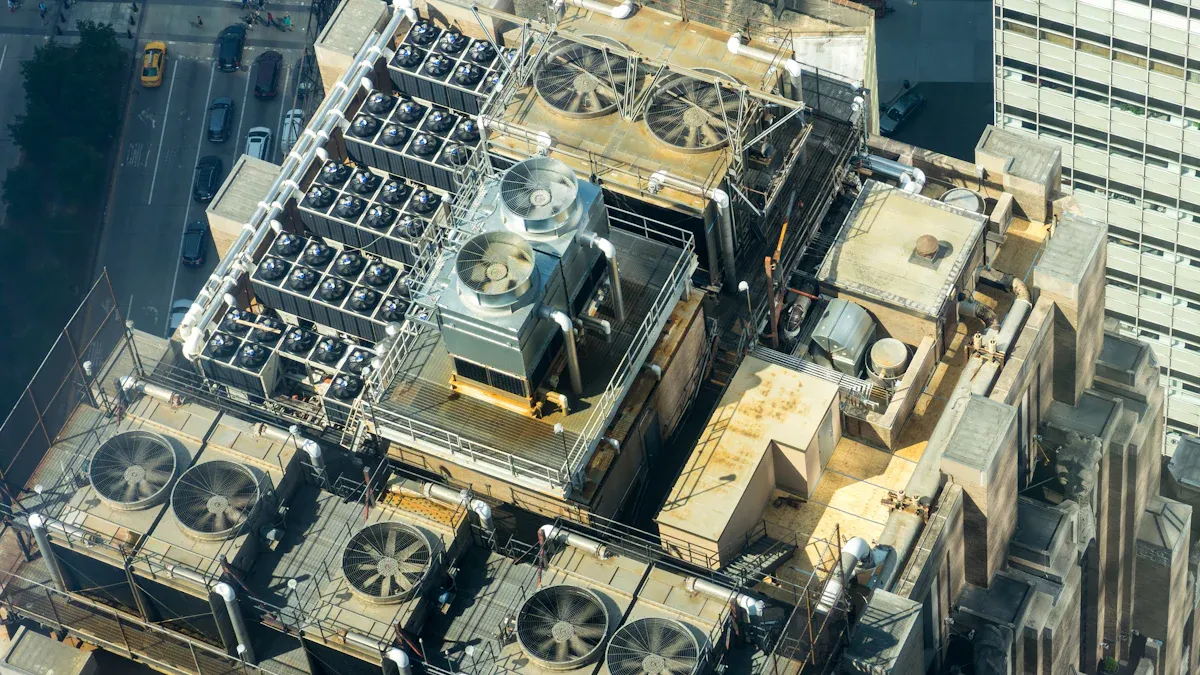

High-quality refrigeration parts play a critical role in ensuring the efficiency and reliability of cooling systems. I have observed that industries such as food processing, pharmaceuticals, and logistics rely heavily on durable components like compressors, evaporators, and condensers. These parts maintain optimal temperatures, ensuring smooth operations and product safety. For example, the logistics sector's growth, particularly in cold chain logistics, highlights the importance of advanced refrigeration systems. Reliable parts directly contribute to operational performance, reducing downtime and maintenance costs.

The demand for efficient cooling solutions continues to rise. Industries prioritize energy-efficient refrigeration systems to meet consumer expectations and comply with health and safety regulations. The table below illustrates key industry benchmarks that emphasize the importance of quality refrigeration parts:

| Evidence Type | Description |

|---|---|

| Increasing Demand for Efficient Cooling | Industries are increasingly favoring efficient refrigeration solutions that offer convenience and energy efficiency. |

| Rising Demand for Frozen Foods | The global demand for frozen and processed foods is rising, necessitating high-quality refrigeration to maintain safety and quality. |

| Technological Advancements | Innovations in refrigeration technology improve performance and attract consumers focused on quality. |

| Health and Safety Regulations | Compliance with strict health and safety regulations ensures the integrity of refrigeration products. |

Certifications and Standards to Ensure Compliance

Certifications and adherence to industry standards validate the quality and performance of refrigeration parts. I always recommend verifying certifications like ISO Standards, Good Manufacturing Practices (GMP), and NBCP Certification when evaluating suppliers. These certifications ensure compliance with international safety and quality benchmarks. For instance, UL Solutions conducts rigorous testing to confirm that refrigeration units meet safety and performance standards. Products bearing recognized marks, such as the UL Mark, assure customers of their reliability.

The following table outlines specific requirements and evidence that enhance compliance in refrigeration parts:

| Requirement | Evidence Needed |

|---|---|

| Temperature sensors installed | Photograph or schematic of all required sensors |

| Sensor accuracy | Photocopy of sensor specification |

| Controller status reporting | Laboratory test description |

| Manual operation initiation | Photocopy of controller manual |

| Fault reporting methods | Supplier’s description and documentation |

| Fault detection capabilities | N/A |

Evaluating the Quality of Wire Tube Condensers

Evaluating the quality of a wire tube condenser requires a combination of quantitative methods and performance analysis. I recommend using exergy analysis to assess energy efficiency and identify areas of improvement. For instance, a domestic refrigerator study utilized thermistors and pressure transducers to measure energy loss within the condenser and evaporator. This approach provides valuable insights into the condenser's efficiency and overall system performance.

Key evaluation methods include:

- Installing thermistors at the condenser's inlet, outlet, and within the wire to monitor temperature variations.

- Using pressure transducers in high- and low-pressure zones to measure performance under different conditions.

Ningbo Senjun New Materials Co., Ltd. excels in producing high-quality wire tube condensers. Their products undergo rigorous testing to ensure durability and efficiency, making them a reliable choice for diverse applications.

Supplier Reliability and Performance

Consistency in Delivery and Lead Times

When selecting a refrigeration parts supplier, I always prioritize consistency in delivery and lead times. Timely deliveries ensure that operations run smoothly without unnecessary delays. To evaluate this, I focus on three key performance metrics:

| Metric | Description |

|---|---|

| On-Time Delivery (OTD) | Measures if products are delivered within the promised timeframe, crucial for maintaining schedules. |

| Perfect Order Fulfillment | Assesses order accuracy in quantity, quality, and timeliness, ensuring all customer expectations are met. |

| Lead Time Variability | Evaluates the consistency of lead times, helping to identify risks in supply chain disruptions. |

Suppliers like Ningbo Senjun New Materials Co., Ltd. excel in maintaining reliable delivery schedules. Their commitment to on-time delivery ensures that critical components, such as wire tube condensers, arrive as promised, minimizing downtime.

Assessing Supplier Track Records and Reviews

A supplier's track record speaks volumes about their reliability. I recommend reviewing customer testimonials, case studies, and industry awards. These provide insights into their performance history. For instance, a supplier with a proven record of fulfilling large-scale orders demonstrates their ability to handle complex demands. Additionally, platforms like trade associations or industry forums often feature reviews that highlight a supplier's strengths and areas of expertise.

Handling Emergency Orders and Unexpected Demands

Emergencies can disrupt even the most well-planned operations. I always assess how suppliers handle urgent orders. Effective management of emergency demands requires prioritization and strategic planning. Research shows that when demand exceeds capacity, delays often occur. However, suppliers that prioritize critical orders and implement efficient strategies can mitigate these challenges.

| Findings | Description |

|---|---|

| Demand Exceeds Capacity | The study found that the demand for emergency orders often surpasses the available capacity of teams, leading to delays. |

| Prioritization of Orders | The research identified criteria for prioritizing commercial and emergency orders, which helps in managing execution times effectively. |

| Handling Rush Orders | The study explores the challenges and solutions in managing rush orders, providing insights into effective strategies for emergency order handling. |

Suppliers like Ningbo Senjun New Materials Co., Ltd. stand out in this regard. Their ability to adapt to unexpected demands ensures that businesses can rely on them during critical situations.

Pricing Transparency and Cost-Effectiveness

Balancing Competitive Pricing with Quality

I always emphasize the importance of balancing competitive pricing with product quality when selecting refrigeration parts suppliers. A lower price may seem attractive, but it often comes at the expense of durability or performance. High-quality components, like wire tube condensers, reduce maintenance costs and extend equipment lifespan. To evaluate this balance, I recommend comparing supplier quotes against industry benchmarks. Reliable suppliers, such as Ningbo Senjun New Materials Co., Ltd., offer competitive pricing without compromising on quality. Their products consistently meet performance expectations, making them a cost-effective choice for long-term use.

Identifying Hidden Costs and Ensuring Transparency

Hidden costs can significantly impact your budget. I advise scrutinizing supplier contracts for additional fees, such as shipping, handling, or expedited delivery charges. Transparent suppliers provide detailed pricing breakdowns, helping you avoid unexpected expenses. For example, I once encountered a supplier who charged extra for packaging materials, which was not disclosed upfront. To prevent such surprises, request a comprehensive cost analysis before finalizing agreements. Suppliers like Ningbo Senjun New Materials Co., Ltd. excel in pricing transparency, ensuring you know exactly what you're paying for.

Tip: Always ask for itemized invoices and clarify terms to ensure full transparency in pricing.

Long-Term Cost Benefits of Reliable Suppliers

Reliable suppliers contribute to long-term cost savings. Their consistent delivery schedules and high-quality products reduce downtime and repair expenses. I have seen businesses achieve significant savings by partnering with suppliers who prioritize durability and efficiency. For instance, Ningbo Senjun New Materials Co., Ltd. specializes in wire tube condensers that enhance energy efficiency, lowering operational costs over time. Investing in dependable suppliers ensures not only immediate savings but also sustained financial benefits for your business.

Product Range and Customization Options

Comprehensive Product Catalogs for Diverse Needs

A supplier with a broad product catalog simplifies procurement and ensures compatibility across various systems. I always look for suppliers offering a wide range of refrigeration parts, from wire tube condensers to copper aluminum fin heat exchangers. This variety allows businesses to source all necessary components from a single provider, reducing logistical complexities. For example, Ningbo Senjun New Materials Co., Ltd. offers an extensive selection of refrigeration solutions tailored to industries like medical, food storage, and retail. Their diverse catalog ensures that businesses can find the right parts for their unique requirements.

Customization for Specific Applications

Customization plays a vital role in meeting specialized needs. I have seen how tailored solutions enhance operational efficiency and customer satisfaction. Suppliers that offer customization options, such as co-designing components, provide significant value. This approach allows businesses to address specific challenges and optimize performance. The table below highlights the economic advantages of customization and extensive product ranges:

| Evidence Description | Economic Advantage |

|---|---|

| Customization creates value for consumers through co-design functions, enhancing consumer experience and satisfaction. | Increased consumer utility and engagement, leading to higher sales. |

| Supply chain integration enhances competitiveness by allowing customizers to work closely with manufacturers. | Improved efficiency and responsiveness in meeting consumer demands. |

| Example of Ralph Lauren's on-demand colored polo shirts illustrates practical application of customization in retail. | Directly meets consumer preferences, potentially increasing market share. |

Suppliers like Ningbo Senjun New Materials Co., Ltd. excel in providing tailored solutions for refrigeration systems, ensuring optimal performance across diverse applications.

Additional Services like Technical Support and Installation

Beyond products, I value suppliers that offer additional services such as technical support and installation. These services simplify the integration process and ensure proper functionality. For instance, technical support can address troubleshooting issues, while professional installation guarantees that components perform as intended. Suppliers like Ningbo Senjun New Materials Co., Ltd. stand out by providing these essential services, helping businesses maintain efficient operations and reduce downtime.

Tip: Always choose suppliers that go beyond just selling products. Their additional services can save time and resources in the long run.

Customer Support and Communication

Responsiveness to Customer Inquiries

Prompt responses to customer inquiries reflect a supplier's commitment to service excellence. I always evaluate how quickly and effectively suppliers address questions or concerns. Clear communication prevents misunderstandings and ensures smooth operations. For instance, service-level agreements (SLAs) often include metrics to measure response times and resolution efficiency. These agreements set clear expectations, ensuring suppliers remain accountable for their performance.

Consistency across communication channels also plays a vital role. Whether through email, phone, or live chat, suppliers must provide uniform and accurate information. This consistency fosters trust and reliability, which are essential for long-term partnerships. Suppliers like Ningbo Senjun New Materials Co., Ltd. excel in maintaining open and responsive communication, ensuring customers receive timely support for products like wire tube condensers.

Availability of Technical Expertise

Technical expertise is a cornerstone of effective customer support. I prioritize suppliers who offer knowledgeable assistance for troubleshooting and product optimization. For example, clarity in technical guidance prevents operational delays and enhances system performance. Feedback loops further improve supplier relationships by addressing recurring issues and refining processes.

Suppliers with robust technical support teams ensure that customers can resolve challenges efficiently. They also provide valuable insights into product applications, such as optimizing the performance of wire tube condensers. This expertise not only saves time but also enhances the overall customer experience.

Building Long-Term Supplier Relationships

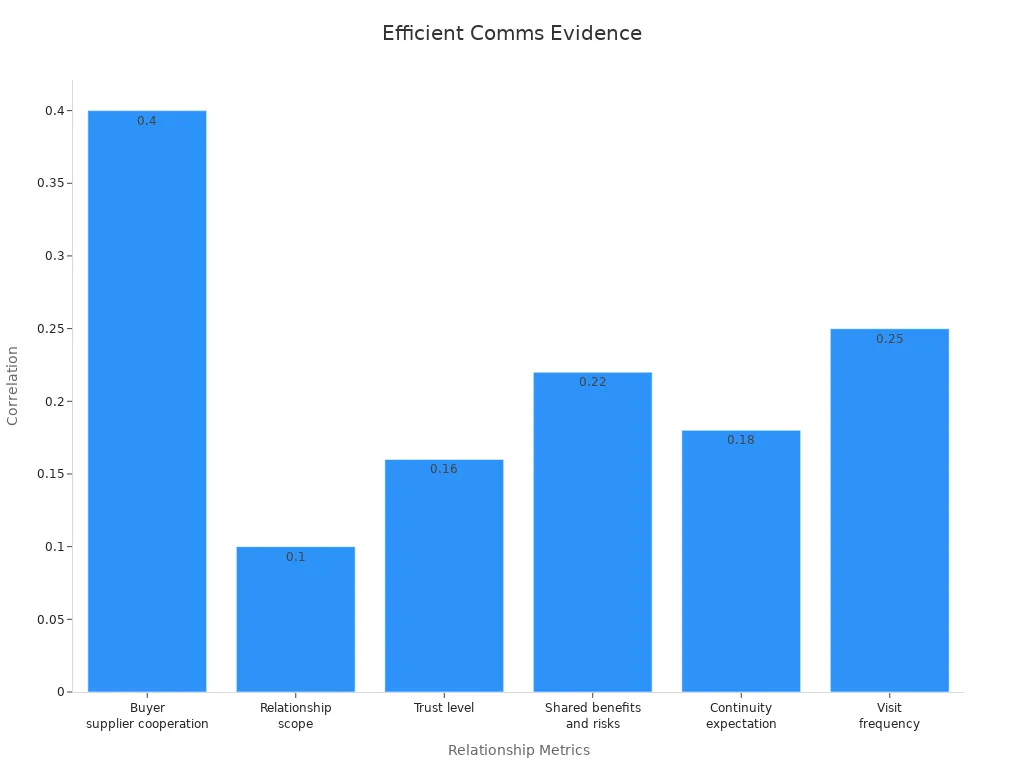

Strong supplier relationships rely on effective communication and mutual trust. I have observed that regular interactions, such as exchanging visits or sharing updates, strengthen these partnerships. The table below highlights key factors that contribute to successful long-term relationships:

| Correlation | Description |

|---|---|

| 0.40 (p < .001) | Cooperation between buyer and supplier |

| 0.10 (p < .05) | Scope of the relationship (number of products provided) |

| 0.16 (p < .01) | Level of trust |

| 0.22 (p < .001) | Perception of shared benefits, burdens, and risks |

| 0.18 (p < .001) | Expectation of continuity in the relationship |

| 0.25 (p < .001) | Extent of visits exchanged between parties |

Suppliers like Ningbo Senjun New Materials Co., Ltd. demonstrate these qualities by fostering trust and collaboration. Their dedication to shared success ensures that businesses can rely on them for consistent quality and support.

Selecting the right refrigeration parts supplier involves evaluating five key metrics: product quality, supplier reliability, pricing transparency, product range, and customer support. These factors ensure operational efficiency and long-term success. I recommend applying these metrics when choosing suppliers like Ningbo Senjun New Materials Co., Ltd., renowned for their expertise in wire tube condensers and copper aluminum fin heat exchangers.

FAQ

What certifications should I look for in a refrigeration parts supplier?

Certifications like ISO Standards, GMP, and UL Mark ensure quality and compliance. These validate the supplier's commitment to safety and performance.

How can I evaluate a supplier's reliability?

Check customer reviews, delivery records, and case studies. Reliable suppliers, like Ningbo Senjun New Materials Co., Ltd., consistently meet deadlines and handle emergency demands effectively.

Why is customization important when choosing a supplier?

Customization ensures components meet specific operational needs. Tailored solutions improve efficiency and compatibility, making them essential for specialized applications.

Tip: Always discuss customization options with your supplier to optimize performance.