How to find reliable copper tube aluminum fin heat exchanger supplie?

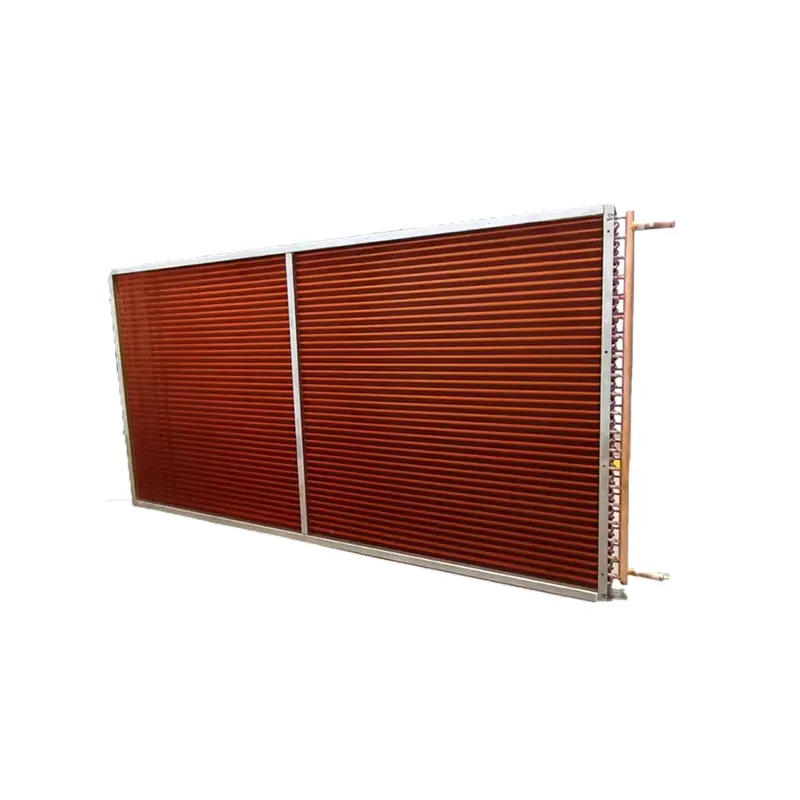

Sourcing a dependable copper tube aluminum fin heat exchanger supplier can be a complex process. I’ve noticed that selecting the right materials, especially aluminum alloys, often poses challenges. For instance, combining alloys to achieve optimal corrosion resistance requires careful consideration. A reliable supplier simplifies this process by offering high-quality Copper Fin Heat Exchanger products tailored to your needs. Their expertise ensures that you receive durable and efficient solutions, whether for refrigerators, dehumidifiers, or other applications. By focusing on quality and trustworthiness, you can avoid costly mistakes and ensure long-term success in your projects.

Key Takeaways

- Choose suppliers with certifications like ASME and AHRI. These show they follow rules and make good products.

- Check how long the supplier has worked in the field. Experienced suppliers know more and handle tough jobs better.

- Read customer reviews or surveys to learn about the supplier. Good reviews mean they are trustworthy and sell quality items.

- Look for suppliers in online directories or at trade shows. These help you find details and talk to suppliers directly.

- Pay attention to product quality and details. Make sure copper and aluminum are strong and work well for your project.

What Defines a Reliable Supplier?

When sourcing a copper tube aluminum fin heat exchanger, I always prioritize finding a supplier who meets specific criteria. A reliable supplier not only delivers quality products but also ensures consistency and trustworthiness. Let me break down the key factors that define such a supplier.

Certifications and Standards

Certifications are a clear indicator of a supplier's commitment to quality and compliance. I always check if the supplier holds relevant certifications, as these validate their adherence to industry standards. Here’s a quick overview of the most common certifications in the heat exchanger industry:

| Certification Type | Source |

|---|---|

| ASME U, UM & R | Finned Tube Heat Exchangers Suppliers |

| UL Listing | Finned Tube Heat Exchangers Suppliers |

| CE Certification | Copper Tube Aluminum Fin condenser |

| RoHS Compliance | Copper Tube Aluminum Fin condenser |

| AHRI Performance Certification | Ensures thermal performance meets published ratings |

These certifications demonstrate that the supplier has undergone rigorous testing and meets global standards. For instance, AHRI Performance Certification ensures that the heat exchanger performs as advertised, which is crucial for applications like refrigerators or dehumidifiers.

Industry Experience

Experience in the industry often translates to reliability. I’ve noticed that suppliers with a long-standing presence tend to have better technical knowledge and a deeper understanding of customer needs. Here are some key aspects I consider:

- Competence: A supplier with a strong reputation and years of experience is more dependable.

- Technical knowledge: Experienced suppliers can address complex requirements effectively.

- Global supply chain: Suppliers with international operations often provide better support and resources.

By choosing a supplier with extensive experience, I ensure that my projects benefit from their expertise and proven track record.

Reputation and Customer Feedback

A supplier’s reputation speaks volumes about their reliability. I always look for customer feedback to gauge their performance. Reviews and ratings, in particular, provide valuable insights. Studies show that 91% of consumers read reviews before making a purchase. Here are some effective ways to gather feedback:

- Surveys (email, post-purchase, or on-site)

- Social media monitoring

- Customer interviews

- Reviews and ratings

I also ensure that feedback is concise and includes both open-ended and closed questions. This approach helps me understand the supplier’s strengths and areas for improvement. A supplier with positive reviews and a strong reputation is more likely to deliver quality products consistently.

Methods to Identify Potential Suppliers

Finding the right supplier for a copper tube aluminum fin heat exchanger requires a strategic approach. I rely on several proven methods to identify potential suppliers, ensuring they meet my quality and reliability standards.

Online Directories and Platforms

Online directories and platforms provide a convenient starting point for supplier research. I often use these tools to access detailed information about manufacturers and their offerings. Some of the most effective directories include:

- IQS Directory: This platform offers a comprehensive list of heat exchanger manufacturers. It includes detailed product descriptions, company profiles, and customer reviews. I find the "request for quote" feature particularly useful for quick inquiries.

- Volza: This directory specializes in listing reliable heat exchanger fin suppliers based on shipment data. It allows me to filter suppliers by shipment frequency, value, and years in operation, ensuring I connect with experienced manufacturers.

Platforms with community feedback and robust verification processes also enhance reliability. Reviews and ratings from other buyers help me assess supplier credibility. Additionally, platforms that verify business licenses and financial stability reduce the risk of fraud. I prioritize user-friendly interfaces with advanced search functions to save time and streamline my search.

Trade Shows and Industry Events

Trade shows and industry events offer unparalleled opportunities to meet suppliers face-to-face. I’ve attended events where I could evaluate products firsthand and discuss technical specifications directly with manufacturers. These events also provide immediate access to customer feedback and vendor ratings. For example, at one trade show, I met a supplier who demonstrated their product’s performance on the spot, which helped me make an informed decision.

I recommend attending trade shows specific to the heat exchanger industry. These events often feature suppliers familiar with technical standards and quality requirements, making them an excellent resource for sourcing.

Referrals and Networking

Referrals and networking remain some of the most reliable methods for finding trustworthy suppliers. I often reach out to industry peers and colleagues for recommendations. Their firsthand experiences provide valuable insights into supplier reliability and product quality. Networking events, both online and offline, also help me build connections with reputable manufacturers.

By leveraging referrals, I gain access to suppliers who have already proven their capabilities. This approach saves time and reduces the risk of engaging with unreliable vendors.

Key Criteria for Evaluating Suppliers

Product Quality and Specifications

When evaluating suppliers, I always prioritize product quality and specifications. High-quality materials like copper tubes and aluminum fins ensure efficient heat transfer and durability. Choosing the right aluminum alloys for components is critical for corrosion resistance, which directly impacts the longevity and efficiency of the heat exchanger. I also assess specific product details to ensure they meet my project requirements.

Here are some key specifications I look for:

- Material: Copper and aluminum for optimal performance.

- Fin Material: Options like hydrophilic or epoxy-coated aluminum for corrosion resistance.

- Tube Diameter: Common sizes include 7mm, 3/8”, and 1/2”.

- Rows: Configurations range from 2 to 12 rows.

- Connections: Options include braze, flare, or threaded fittings.

- Casing: Materials like galvanized steel or stainless steel for durability.

| Specification | Details |

|---|---|

| Material | Copper (Cu), Aluminum (AL) |

| Fin Material | Aluminum, Pre-coated; Hydrophilic, Corrosion resistant, Epoxy |

| Tube O.D. | 7mm, 3/8”, 1/2” |

| Rows | 2, 3, 4, 5, 6, 8, 10, 12 |

| Connections | Braze, Flare, Fitting, threaded (steel, brass, Aluminum) |

| Casing / Mounting | Galvanized Steel, Stainless Steel, Carbon Steel, Copper or Aluminum |

| Fin Surface | Various |

| Options | Side port connection, E-Coat |

By focusing on these specifications, I ensure the copper tube aluminum fin heat exchanger I source aligns with my performance and durability expectations.

Pricing and Cost-Effectiveness

Pricing plays a significant role in supplier evaluation, but I avoid focusing solely on cost. A low price often compromises quality, delivery, or innovation. Instead, I balance cost with value by considering factors like material quality and supplier responsiveness.

Here’s a typical pricing structure I’ve encountered:

| Quantity Range | Price per Unit |

|---|---|

| 500 - 1499 pieces | $80.00 |

| 1500 - 2999 pieces | $70.00 |

| 3000 pieces or more | $60.00 |

| Sample Price | $10.00 (max 5 pieces) |

This tiered pricing model helps me plan bulk purchases effectively. I also ensure that the supplier’s pricing aligns with my budget without sacrificing essential features or quality.

Delivery Timelines and Flexibility

Timely delivery is crucial for maintaining project schedules. I always verify a supplier’s ability to meet deadlines and adapt to changes. Flexible suppliers who can handle urgent orders or adjust timelines for unforeseen circumstances add significant value.

I assess their logistics capabilities by asking about lead times, shipping methods, and contingency plans. A reliable supplier provides clear timelines and communicates proactively about potential delays. This ensures that I can plan my projects without disruptions.

By focusing on these criteria, I consistently find suppliers who deliver quality products on time and within budget.

Customer Service and Support

Customer service and support play a critical role in supplier evaluation. I always prioritize suppliers who demonstrate a commitment to assisting their clients throughout the purchasing process. A supplier’s responsiveness and problem-solving ability can significantly impact the success of my projects.

I assess customer service by observing how quickly suppliers respond to inquiries. Prompt replies indicate that the supplier values my time and is eager to address my concerns. For example, when I request technical specifications or pricing details, I expect a detailed response within 24 to 48 hours. Delayed or vague replies often signal a lack of professionalism.

Support services extend beyond communication. I look for suppliers who offer technical assistance, especially when dealing with complex products like a copper tube aluminum fin heat exchanger. A knowledgeable support team can guide me through installation, maintenance, and troubleshooting. This level of expertise ensures that I maximize the performance and lifespan of the product.

Another factor I consider is after-sales support. Reliable suppliers provide warranties, replacement parts, and repair services. These offerings demonstrate their confidence in the quality of their products. I also value suppliers who follow up after delivery to ensure my satisfaction. This proactive approach builds trust and fosters long-term relationships.

In my experience, excellent customer service and support distinguish top-tier suppliers from the rest. By choosing a supplier who prioritizes client needs, I ensure a smooth and efficient sourcing process.

Verifying Supplier Credibility

Verifying a supplier’s credibility is essential to ensure quality and reliability. I use several methods to confirm that a supplier can meet my expectations and deliver consistent results.

Reviews and References

I always start by examining reviews and references. Customer testimonials provide valuable insights into a supplier’s reliability and product quality. I also request references from existing clients to gauge their satisfaction. Conducting thorough background checks helps me verify the supplier’s registration documents and business licenses. This step ensures I work with a legitimate and trustworthy partner.

Here’s a quick overview of the most reliable methods for verifying reviews and references:

| Method | Description |

|---|---|

| Conduct thorough background checks | Gather detailed information about the supplier, including registration documents and business licenses. |

| Seek customer testimonials | Ask for references from existing clients to gauge satisfaction and reliability. |

| Assess certifications and compliance | Check for industry certifications like ISO to ensure supplier reliability. |

| Evaluate communication and transparency | Assess the supplier's responsiveness and willingness to share information, indicating their credibility. |

These steps help me identify suppliers who prioritize transparency and customer satisfaction.

Product Samples

Evaluating product samples is a critical step in assessing supplier credibility. I always request samples to examine the quality and craftsmanship of their products. This process allows me to identify any discrepancies between the sample quality and actual deliveries. For instance, when sourcing a copper tube aluminum fin heat exchanger, I ensure the sample meets my specifications for material, durability, and performance.

Product samples also provide insight into the supplier’s production procedures and quality control techniques. By comparing the sample with my project requirements, I can determine if the supplier aligns with my expectations. This step minimizes risks and ensures I receive high-quality products.

Facility Visits

Visiting a supplier’s facility offers a firsthand look at their operations and quality standards. I assess their production capabilities, including equipment and quality control procedures. Face-to-face communication during these visits helps me build trust and reduce misunderstandings.

Facility visits also ensure compliance with legal, ethical, and social responsibility standards. I observe health and safety practices, labor conditions, and environmental policies. However, challenges like language barriers or limited physical access can arise. In such cases, I rely on virtual tours, third-party audits, or real-time video feeds to verify operations.

This approach gives me confidence in the supplier’s ability to meet my requirements while maintaining ethical practices.

Building Long-Term Supplier Relationships

Negotiation Strategies

Building long-term supplier relationships starts with effective negotiation. I approach negotiations as a collaborative effort rather than a competitive battle. This mindset fosters trust and mutual benefits. For example, Toyota’s collaborative supplier relationships have enabled it to handle supply chain disruptions better than many competitors.

Toyota is known for its collaborative supplier relationships, which have helped it navigate supply chain disruptions more effectively than many competitors.

I follow a structured approach to negotiation:

- Adopt a collaborative mindset.

- Practice effective communication.

- Demonstrate ongoing value.

- Make strategic concessions.

- Foster a partnership mentality.

Exploring innovative contracting models, such as shared risk and reward mechanisms, also strengthens partnerships. These strategies ensure that both parties feel valued and committed to the relationship.

Communication and Collaboration

Effective communication is the backbone of supplier collaboration. I establish clear expectations from the outset, including specifications, quality standards, and delivery schedules. Open and transparent communication builds trust and encourages problem-solving.

To enhance collaboration, I leverage technology like project management systems and shared document platforms. These tools streamline information exchange and reduce errors. Regular performance reviews also play a crucial role. They foster accountability and drive continuous improvement.

Here are some practices I follow to maintain strong communication:

- Create a space for open dialogue to address concerns promptly.

- Use technology to facilitate efficient collaboration.

- Conduct regular meetings to discuss production forecasts and performance metrics.

By prioritizing clear and consistent communication, I ensure fewer shortages and more on-time deliveries.

Performance Monitoring

Monitoring supplier performance is essential for maintaining quality and reliability. I track key metrics to evaluate their adherence to standards and identify areas for improvement.

| Metric | Description |

|---|---|

| Defect Rate | Measures the percentage of products or services that fail to meet quality standards. |

| On-Time Delivery Rate | Tracks the percentage of orders delivered on or before the scheduled delivery date. |

| Lead Time | Measures the time taken from order placement to delivery. |

| Total Cost of Ownership (TCO) | Evaluates the overall cost associated with a supplier, including direct and indirect costs. |

| Sustainability Practices | Assesses the supplier’s commitment to environmental and social responsibility. |

I also use supplier scorecards to report on these metrics regularly. This practice ensures transparency and helps me provide constructive feedback. By monitoring performance consistently, I maintain high standards and foster continuous improvement in my supplier relationships.

Sourcing a reliable copper tube aluminum fin heat exchanger supplier is essential for ensuring quality and cost-effectiveness in your projects. I recommend following a structured approach to identify, evaluate, and verify potential suppliers. Start by assessing their competence, technical expertise, and responsiveness. Thorough evaluation helps eliminate poor performers, reducing costs and improving product quality. Building strong relationships with suppliers offers long-term benefits like better pricing, enhanced communication, and increased flexibility. By applying these steps, you can secure dependable partners and achieve consistent success in your sourcing efforts.

FAQ

What are the key certifications to look for in a supplier?

I always check for certifications like ASME, CE, and RoHS. These validate the supplier’s adherence to global standards. AHRI Performance Certification is also crucial as it ensures the product meets advertised thermal performance ratings.

How can I verify a supplier’s credibility?

I recommend requesting product samples and conducting facility visits. Reviews and references from existing clients also provide valuable insights. These steps help confirm the supplier’s reliability and quality standards.

Why is industry experience important when choosing a supplier?

Experienced suppliers possess technical expertise and a deep understanding of customer needs. They can handle complex requirements effectively and often have robust global supply chains, ensuring consistent quality and support.

What should I prioritize when evaluating product quality?

Focus on materials like copper and aluminum for durability and efficiency. Check specifications such as tube diameter, fin material, and casing. These factors directly impact the heat exchanger’s performance and lifespan.

How do I build a long-term relationship with a supplier?

I emphasize clear communication, regular performance reviews, and collaborative negotiation strategies. Establishing mutual trust and aligning goals ensures a strong partnership, leading to better pricing, flexibility, and consistent quality.