How to choose a suitable finned heat exchanger?

2024-12-07

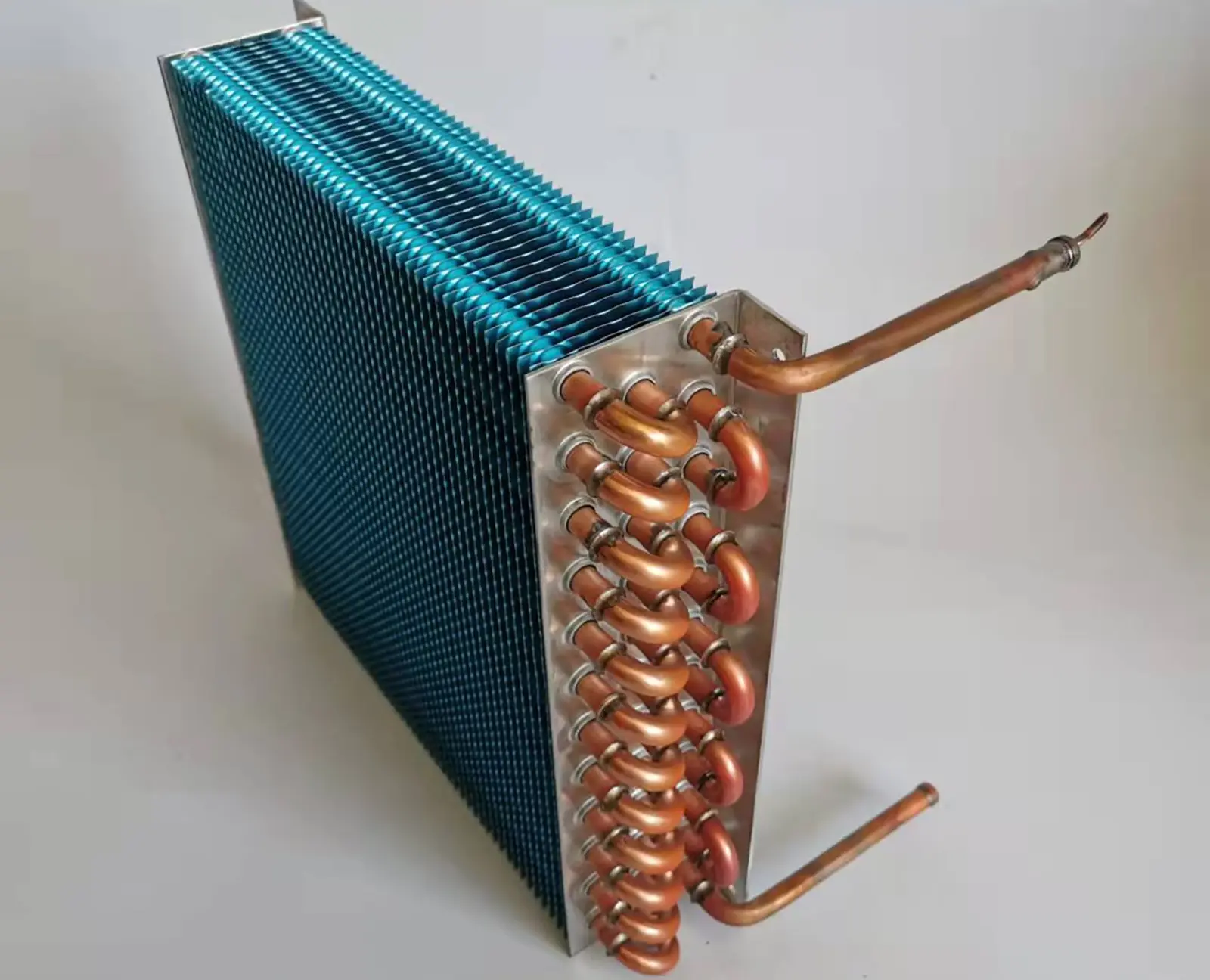

Fin-tube heat exchangers have been widely used in the petroleum, chemical, light industry, power, metallurgy, machinery, energy and other industries.

One of the more competitive varieties in the heat exchanger family. Since the 1960s, China has been producing plate-type heat exchangers, which have been widely used in many fields in China. With the continuous development and innovation of China's manufacturing industry, the quality of domestic mechanical equipment has been constantly improved. The quality of domestic equipment is no worse than that of foreign brands. Therefore, nowadays, enterprises are more inclined to purchase domestic equipment. The development of plate-type heat exchangers is quite good. Plate-type heat exchangers play a very important role in the field of heat exchange.

There are many heat exchanger manufacturers now, and the quality is of varying quality. When choosing a finned heat exchanger, companies face a variety of products from different manufacturers and are unsure of how to choose - afraid of choosing the wrong one, afraid of choosing the expensive one. The proliferation of online marketing has also made it harder for us to find genuine information. So how do you choose a plate heat exchanger manufacturer and how do you choose the right plate heat exchanger for yourself?

In general, we mainly distinguish plate heat exchangers based on their structure, i.e. by appearance, which can be divided into four categories: ① Removable plate heat exchangers (also known as plate heat exchangers with gaskets), ② Welded plate heat exchangers, ③ Spiral plate heat exchangers, and ④ Plate coil heat exchangers (also known as honeycomb heat exchangers). Among them, welded plate heat exchangers are divided into semi-welded plate heat exchangers and fully welded plate heat exchangers, as well as welded plate heat exchangers, shell and tube heat exchangers, and brazed plate heat exchangers.

(1) Choose a reputable and reliable plate heat exchanger manufacturer. First, analyze and compare each manufacturer found through internet search, and select two to three strong ones. Then, visit the manufacturer's production scale, physical factory, production equipment, and technical personnel in person to select a reliable heat exchanger manufacturer.

(2) Before selecting a heat exchanger, you need to have a detailed understanding of your heat exchange conditions and specific operating environment. Consult with technical personnel for selection and design. Conventional heat exchanger manufacturers will have professional technical personnel who can design a suitable heat exchanger based on the information parameters you provide. This provides a great convenience for companies purchasing plate heat exchangers.

(3) Consider the economic performance. A high-efficiency heat exchanger does not necessarily mean it is suitable. In fact, a heat exchanger with a small heat transfer area and a large heat transfer area has good economic and performance advantages.

(4) Look at the material of the finned heat exchanger. A good heat exchanger manufacturer will not be stingy with the material, and high-quality original heat exchanger materials have a great impact on the service life, heat exchange efficiency, etc. of the heat exchanger.

(5) Assembly and after-sales service of plate heat exchangers.

One of the more competitive varieties in the heat exchanger family. Since the 1960s, China has been producing plate-type heat exchangers, which have been widely used in many fields in China. With the continuous development and innovation of China's manufacturing industry, the quality of domestic mechanical equipment has been constantly improved. The quality of domestic equipment is no worse than that of foreign brands. Therefore, nowadays, enterprises are more inclined to purchase domestic equipment. The development of plate-type heat exchangers is quite good. Plate-type heat exchangers play a very important role in the field of heat exchange.

There are many heat exchanger manufacturers now, and the quality is of varying quality. When choosing a finned heat exchanger, companies face a variety of products from different manufacturers and are unsure of how to choose - afraid of choosing the wrong one, afraid of choosing the expensive one. The proliferation of online marketing has also made it harder for us to find genuine information. So how do you choose a plate heat exchanger manufacturer and how do you choose the right plate heat exchanger for yourself?

In general, we mainly distinguish plate heat exchangers based on their structure, i.e. by appearance, which can be divided into four categories: ① Removable plate heat exchangers (also known as plate heat exchangers with gaskets), ② Welded plate heat exchangers, ③ Spiral plate heat exchangers, and ④ Plate coil heat exchangers (also known as honeycomb heat exchangers). Among them, welded plate heat exchangers are divided into semi-welded plate heat exchangers and fully welded plate heat exchangers, as well as welded plate heat exchangers, shell and tube heat exchangers, and brazed plate heat exchangers.

(1) Choose a reputable and reliable plate heat exchanger manufacturer. First, analyze and compare each manufacturer found through internet search, and select two to three strong ones. Then, visit the manufacturer's production scale, physical factory, production equipment, and technical personnel in person to select a reliable heat exchanger manufacturer.

(2) Before selecting a heat exchanger, you need to have a detailed understanding of your heat exchange conditions and specific operating environment. Consult with technical personnel for selection and design. Conventional heat exchanger manufacturers will have professional technical personnel who can design a suitable heat exchanger based on the information parameters you provide. This provides a great convenience for companies purchasing plate heat exchangers.

(3) Consider the economic performance. A high-efficiency heat exchanger does not necessarily mean it is suitable. In fact, a heat exchanger with a small heat transfer area and a large heat transfer area has good economic and performance advantages.

(4) Look at the material of the finned heat exchanger. A good heat exchanger manufacturer will not be stingy with the material, and high-quality original heat exchanger materials have a great impact on the service life, heat exchange efficiency, etc. of the heat exchanger.

(5) Assembly and after-sales service of plate heat exchangers.