How Eco-Friendly Refrigeration Parts Help Companies Achieve Carbon Neutrality

Reducing energy consumption and greenhouse gas emissions is critical for companies striving for carbon neutrality. Eco-friendly refrigeration parts play a pivotal role in this effort. For instance, energy-efficient systems utilizing low-GWP refrigerants significantly lower electricity usage, which is vital since cooling equipment accounts for a substantial share of climate emissions. Companies adopting these solutions not only align with sustainability goals but also enjoy reduced operational costs and enhanced reputations. Ningbo Senjun New Materials Co., Ltd. exemplifies innovation in this space by producing advanced components like the wire tube condenser, which supports sustainable refrigeration practices across industries.

Key Takeaways

- Green refrigeration parts use less energy and cut costs, saving money.

- Natural coolants like CO2 and ammonia lower harmful gas emissions, aiding carbon neutrality.

- Businesses can improve their reputation by going green, drawing eco-friendly customers.

- Working with suppliers like Ningbo Senjun provides smart, green parts that work better.

- Teaching workers about new systems and checking progress helps get the most from eco-friendly refrigeration.

Understanding Carbon Neutrality and Eco-Friendly Refrigeration

Defining Carbon Neutrality

Carbon neutrality means balancing the carbon dioxide emitted into the atmosphere with the amount removed through carbon sinks. This process, known as carbon sequestration, involves capturing and storing carbon to offset emissions. Achieving net zero emissions requires industries to reduce greenhouse gas emissions while compensating for any remaining output. This concept has become a cornerstone of global sustainability efforts, with businesses adopting innovative technologies to meet these goals.

What Makes Refrigeration Parts Eco-Friendly?

Eco-friendly refrigeration parts are designed to minimize environmental impact while maintaining efficiency. Several criteria determine their sustainability:

| Criteria | Description |

|---|---|

| Ozone Depletion Potential (ODP) | Measures the potential of a substance to deplete the ozone layer; lower values are more eco-friendly. |

| Global Warming Potential (GWP) | Assesses a substance's ability to trap heat in the atmosphere; lower values indicate less impact on climate change. |

| Toxicity | Evaluates the harmful effects on human health; eco-friendly refrigerants should have lower toxicity. |

| Flammability | Considers the safety risks associated with refrigerants; lower flammability is preferred for safety. |

The industry is shifting toward natural refrigerants like CO2 and ammonia due to their low GWP and energy efficiency. These alternatives not only reduce emissions but also align with global initiatives like the Kigali Amendment, which aims to cut HFC consumption by over 80% by 2045.

The Role of Wire Tube Condensers in Sustainable Refrigeration

Wire tube condensers play a critical role in advancing sustainable refrigeration. These components, such as those developed by Ningbo Senjun New Materials Co., Ltd., enhance energy efficiency by optimizing heat exchange processes. By reducing energy consumption, they help businesses lower operational costs and carbon footprints. Additionally, wire tube condensers are compatible with eco-friendly refrigerants, making them an ideal choice for companies transitioning to greener systems. Their versatility allows them to be used in various applications, from refrigerators to medical ultra-low temperature units, further supporting carbon neutrality goals.

Environmental Impact of Traditional Refrigeration Systems

Energy Consumption and Carbon Footprint

Traditional refrigeration systems consume significant amounts of energy, contributing heavily to carbon emissions. I have observed that HVAC systems, which include refrigeration units, are among the largest energy consumers in commercial and industrial sectors. This high energy demand drives the search for renewable energy sources and energy-efficient technologies.

- Refrigerants used in these systems are potent greenhouse gases, with global warming potentials (GWPs) far exceeding that of CO2.

- Compliance with standards like Energy Star and DOE regulations can reduce energy consumption, lower operating costs, and even qualify businesses for government incentives.

Switching to energy-efficient refrigeration components, such as wire tube condensers, can significantly reduce the carbon footprint of these systems. Companies adopting these solutions not only save energy but also enhance the performance and longevity of their equipment.

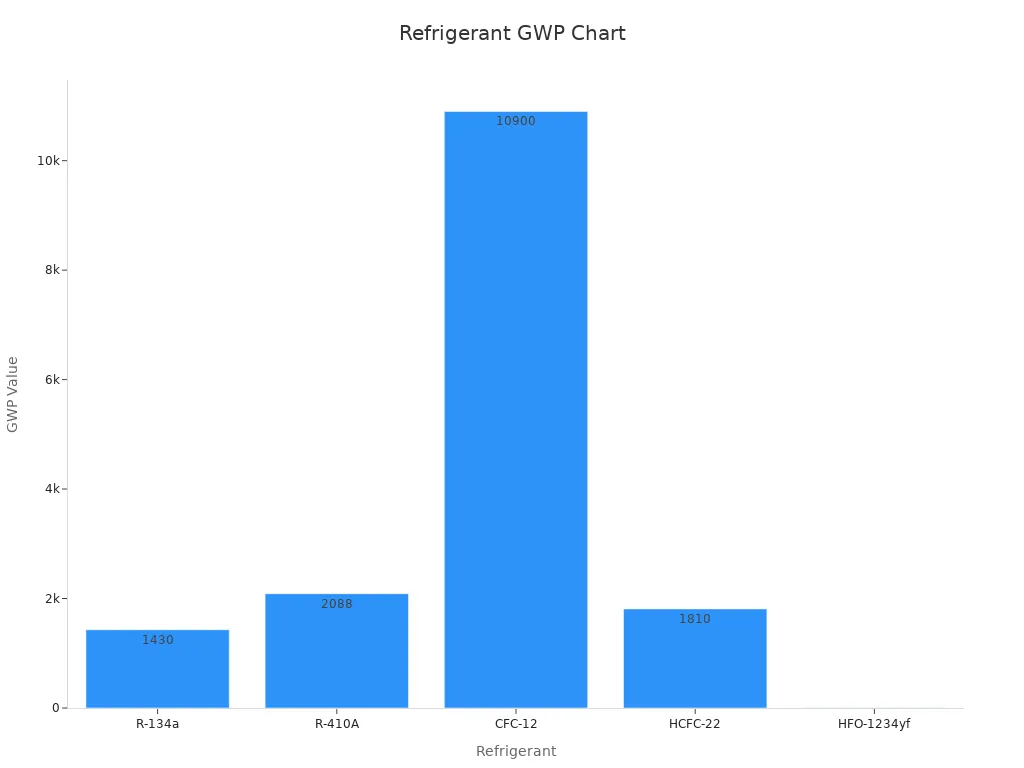

Greenhouse Gas Emissions from Refrigerants

The refrigerants used in traditional systems are a major source of greenhouse gas emissions. Many of these substances, such as CFCs and HCFCs, have alarmingly high GWP values. For example:

| Refrigerant | GWP Value |

|---|---|

| R-134a | 1,430 |

| R-410A | 2,088 |

| CFC-12 | 10,900 |

| HCFC-22 | 1,810 |

| HFO-1234yf | 4 |

One kilogram of R-410A has the same greenhouse effect as two tons of CO2. This highlights the urgent need to transition to eco-friendly refrigerants like HFO-1234yf, which has a GWP of just 4.

Why the Industry Needs Sustainable Alternatives

Over 90% of traditional refrigerants contribute to global warming. This alarming statistic underscores the importance of adopting sustainable alternatives. Eco-friendly refrigerants not only reduce greenhouse gas emissions but also improve energy efficiency. Stricter regulations and rising demand across industries further emphasize the need for change.

By transitioning to sustainable refrigeration components, companies can align with environmental standards, reduce their carbon footprints, and support global efforts to combat climate change. Solutions like those offered by Ningbo Senjun New Materials Co., Ltd. provide a clear path toward a greener future.

Benefits of Eco-Friendly Refrigeration Parts for Companies

Lower Energy Usage and Operational Costs

Eco-friendly refrigeration parts significantly reduce energy consumption, which directly lowers operational costs. I have seen how components like CO2 and ammonia-based systems excel in energy efficiency. These refrigerants, known for their high latent heat of vaporization, enable smaller and more efficient systems. This efficiency translates into reduced energy bills over time.

- CO2 refrigeration systems outperform traditional systems in energy efficiency.

- Ammonia-based systems offer exceptional cooling performance, requiring less energy to achieve the same results.

Case studies further highlight these benefits. For example:

| Case Study Title | Description |

|---|---|

| Refrigeration control retrofit moves the retail profitability needle | The CC200 case controller delivered energy and operational savings for a leading international retailer. |

| Future Footprint: CO₂ System Offers Small-format Retail Sustainability | A fully integrated CO₂ refrigeration system helped Kwik Trip convenience stores achieve next-generation refrigerant strategies. |

These examples demonstrate how adopting advanced refrigeration technologies can lead to substantial cost savings while supporting sustainability goals.

Reduced Greenhouse Gas Emissions

Eco-friendly refrigeration parts also play a vital role in reducing greenhouse gas emissions. Traditional refrigerants like R-134a and R-410A have high global warming potentials (GWPs), contributing significantly to climate change. In contrast, natural refrigerants such as CO2 and ammonia have minimal environmental impact.

For instance, CO2 has a GWP of 1, making it a far more sustainable choice than conventional refrigerants. By switching to these alternatives, companies can drastically lower their carbon footprints. Additionally, components like the wire tube condenser enhance system efficiency, further reducing emissions by minimizing energy waste.

Compliance with Environmental Standards

Regulatory frameworks increasingly demand the adoption of eco-friendly refrigeration solutions. I have observed how international agreements like the Montreal Protocol and Kigali Amendment have driven the industry toward sustainable practices.

| Regulatory Framework | Description |

|---|---|

| Montreal Protocol | Phased out ozone-depleting substances, encouraging the development of eco-friendly refrigerants. |

| Kigali Amendment | Aims to phase down HFCs, promoting the use of sustainable alternatives. |

| EPA AIM Act | Targets an 85% phasedown of HFCs by 2036, significantly reducing CO2 equivalent emissions. |

These regulations not only protect the environment but also provide businesses with incentives to adopt greener technologies. Companies that comply with these standards can avoid penalties, qualify for government incentives, and enhance their reputation as environmentally responsible organizations.

Improved Brand Image and Customer Trust

Adopting eco-friendly refrigeration parts strengthens a company’s reputation. I have seen how businesses that prioritize sustainability gain recognition as industry leaders. Customers increasingly value brands that demonstrate environmental responsibility. By integrating components like wire tube condensers from Ningbo Senjun New Materials Co., Ltd., companies showcase their commitment to reducing carbon footprints.

Tip: Highlighting sustainable practices in marketing campaigns can amplify customer engagement and loyalty.

Eco-friendly refrigeration systems also appeal to environmentally conscious consumers. Many individuals prefer brands that align with their values. When businesses invest in sustainable technologies, they foster trust and loyalty among these customers. For example, a retail chain that transitions to energy-efficient refrigeration systems can promote its green initiatives through social media, attracting a broader audience.

I have observed that regulatory compliance further enhances brand credibility. Companies that meet environmental standards demonstrate accountability and transparency. This builds trust not only with customers but also with stakeholders and investors. For instance, businesses that adopt low-GWP refrigerants and energy-efficient components signal their dedication to long-term sustainability.

Additionally, partnerships with innovative suppliers like Ningbo Senjun New Materials Co., Ltd. elevate a company’s image. Collaborating with industry leaders in sustainable refrigeration reflects a proactive approach to environmental challenges. This positions the brand as forward-thinking and socially responsible.

🌱 Key Takeaway: Eco-friendly refrigeration parts are more than operational tools—they are strategic assets that enhance brand image and foster customer trust. By embracing these solutions, companies can differentiate themselves in competitive markets while contributing to a sustainable future.

Steps to Transition to Eco-Friendly Refrigeration

Choosing the Right Components, Including Wire Tube Condensers

Selecting the right refrigeration components is the foundation of a successful transition to eco-friendly systems. I always recommend prioritizing parts that enhance energy efficiency and reduce environmental impact. For instance, wire tube condensers, like those developed by Ningbo Senjun New Materials Co., Ltd., are an excellent choice. These components optimize heat exchange, which minimizes energy consumption and supports the use of natural refrigerants such as CO2 and ammonia.

Natural refrigerants are gaining traction due to their low global warming potential (GWP) and zero ozone depletion potential (ODP). Options like isobutane and isopropane also align with sustainability goals. Governments and industry experts encourage this shift, offering financial incentives and grants to offset initial costs. By choosing components compatible with these refrigerants, businesses can future-proof their systems while meeting environmental standards.

Partnering with Sustainable Suppliers Like Senjun

Collaborating with sustainable suppliers ensures access to high-quality, eco-friendly refrigeration components. I have seen how partnerships with companies like Ningbo Senjun New Materials Co., Ltd. drive innovation and sustainability. Senjun specializes in wire tube condensers and other advanced solutions that cater to various applications, from medical refrigeration to display cabinets.

Sustainable suppliers also help businesses achieve key performance indicators (KPIs) related to environmental goals. For example:

| Sustainability KPI | Measurement Unit |

|---|---|

| CO2 emissions reduction | kt |

| Energy consumption | kWh |

| Compliance with environmental standards | N/A |

These partnerships not only improve operational efficiency but also enhance a company’s public image. Businesses adopting eco-friendly technologies often benefit from increased customer loyalty and government incentives.

Leveraging Technology for Energy Efficiency

Technological advancements play a crucial role in improving energy efficiency. I recommend integrating solutions like variable-speed compressors and phase-change materials (PCMs) to enhance system performance. These innovations reduce energy consumption and improve reliability.

Natural refrigerants, such as CO2, further boost efficiency. Transcritical CO2 systems, for example, are projected to grow due to their superior heating and cooling capabilities. Additionally, nano refrigerants are emerging as a game-changer by increasing heat transfer rates. Rising energy costs make these technologies essential for businesses aiming to cut expenses while reducing their carbon footprint.

By adopting these advancements, companies can achieve significant energy savings and contribute to global sustainability efforts.

Training Teams and Monitoring Performance

Transitioning to eco-friendly refrigeration systems requires more than just upgrading equipment. I have found that training teams and monitoring performance are critical steps in ensuring long-term success. Employees need to understand how to operate and maintain these advanced systems effectively. Without proper training, even the most efficient components may fail to deliver their full potential.

Key Areas for Team Training

I always recommend focusing on these areas during training sessions:

- System Operation: Teach employees how to use eco-friendly components like wire tube condensers. This ensures optimal performance and energy efficiency.

- Maintenance Protocols: Equip teams with the knowledge to perform routine checks and identify potential issues early.

- Safety Measures: Highlight the safe handling of natural refrigerants like CO2 and ammonia, which require specific precautions.

- Sustainability Goals: Help employees understand how their actions contribute to the company’s carbon neutrality objectives.

Tip: Hands-on workshops and interactive training modules often yield better results than traditional lectures. Employees retain more information when they actively participate.

Monitoring Performance for Continuous Improvement

Once the team is trained, monitoring system performance becomes essential. I suggest using key performance indicators (KPIs) to track progress. For example:

| KPI | Measurement Unit | Purpose |

|---|---|---|

| Energy Consumption | kWh | Identify areas for efficiency gains. |

| Refrigerant Leakage Rate | % | Ensure minimal environmental impact. |

| System Downtime | Hours | Maintain operational reliability. |

Regular performance reviews help identify gaps and provide opportunities for further training. Advanced monitoring tools, such as IoT-enabled sensors, can automate data collection and analysis. These technologies allow businesses to make informed decisions and adapt quickly to changing conditions.

🌱 Key Takeaway: Training teams and monitoring performance are not optional—they are essential for maximizing the benefits of eco-friendly refrigeration systems. By investing in these areas, companies can achieve operational excellence and sustainability goals simultaneously.

Real-World Success Stories

How a Retail Chain Reduced Emissions with Wire Tube Condensers

I have seen how retail chains can significantly lower emissions by adopting advanced refrigeration technologies. One notable example involves the use of wire tube condensers, which optimize heat exchange and reduce energy consumption. These components, like those developed by Ningbo Senjun New Materials Co., Ltd., are compatible with eco-friendly refrigerants, making them ideal for sustainable operations.

Research supports this transition. For instance, Padmavathy et al. evaluated low-GWP refrigerants and found that a 90:10 blend of R1234ze and R134a performed exceptionally well in low-temperature applications. Similarly, Mohapatra et al. observed that natural refrigerants not only mitigate environmental impacts but also enhance system reliability. These findings demonstrate the potential of combining innovative components with sustainable refrigerants to achieve carbon neutrality.

A Food Manufacturer’s Journey to Carbon Neutrality

Food manufacturers face unique challenges in reducing their carbon footprints. I have observed how CO2 refrigeration systems have become a game-changer in this sector. These systems perform efficiently in both low and high ambient temperatures, making them versatile for applications like food processing plants and supermarkets.

Since 2020, the adoption of high-efficiency, low-GWP refrigerant products has helped customers avoid over 367 million metric tons of greenhouse gas emissions. CO2 systems also consume less energy than traditional refrigeration systems, leading to reduced operational costs. This dual benefit of energy efficiency and emission reduction makes them a preferred choice for manufacturers aiming to achieve carbon neutrality.

Lessons from Industry Leaders in Sustainable Refrigeration

Industry leaders in sustainable refrigeration offer valuable insights. I have learned that phasing out harmful refrigerants like HFCs is a critical step. These gases are significantly more potent than CO2 as greenhouse contributors. Over 4,000 supermarkets and four million chiller units now use low-carbon systems, showcasing the industry's commitment to natural refrigerants.

Continuous innovation and collaboration have also proven essential. Companies share best practices and work together to overcome barriers, driving progress in sustainable refrigeration. These efforts highlight the importance of partnerships and a proactive approach to achieving environmental goals.

Key Takeaway: Real-world examples show that adopting eco-friendly refrigeration components, such as wire tube condensers, not only reduces emissions but also enhances operational efficiency. Businesses can learn from these success stories to implement sustainable practices effectively.

Eco-friendly refrigeration parts, such as the wire tube condenser, offer a practical path for companies aiming to achieve carbon neutrality. These components reduce energy consumption and greenhouse gas emissions while aligning with global sustainability goals. For example, natural refrigerants like ammonia and CO2 boast zero ozone depletion potential and low global warming potential, making them ideal for sustainable systems. Governments worldwide are also incentivizing businesses to adopt these technologies through financial support and regulations. Companies like Ningbo Senjun New Materials Co., Ltd. are leading this transformation, providing innovative solutions that help businesses save costs, enhance efficiency, and build a greener future.

FAQ

What are the key benefits of using wire tube condensers in refrigeration systems?

Wire tube condensers improve energy efficiency by optimizing heat exchange. They reduce energy consumption, lower operational costs, and support the use of eco-friendly refrigerants. Their versatility allows them to be used in various applications, from refrigerators to medical cooling systems, making them essential for sustainable refrigeration.

How do eco-friendly refrigeration parts help achieve carbon neutrality?

Eco-friendly parts minimize energy usage and greenhouse gas emissions. Components like wire tube condensers enhance system efficiency, while natural refrigerants like CO2 and ammonia reduce environmental impact. These technologies align with carbon neutrality goals by lowering the carbon footprint of refrigeration systems.

Why should companies partner with sustainable suppliers like Ningbo Senjun?

Partnering with sustainable suppliers ensures access to high-quality, eco-friendly components. Ningbo Senjun specializes in innovative solutions like wire tube condensers, which support energy efficiency and sustainability. Collaborating with such suppliers helps businesses meet environmental standards, reduce costs, and enhance their reputation as eco-conscious organizations.

Are natural refrigerants safe to use in refrigeration systems?

Yes, natural refrigerants like CO2 and ammonia are safe when handled correctly. Proper training and adherence to safety protocols ensure their safe use. These refrigerants offer low global warming potential and zero ozone depletion, making them ideal for sustainable refrigeration systems.

How can businesses monitor the performance of eco-friendly refrigeration systems?

Businesses can track performance using key performance indicators (KPIs) like energy consumption, refrigerant leakage rates, and system downtime. IoT-enabled sensors and advanced monitoring tools provide real-time data, enabling companies to identify inefficiencies and optimize system performance for long-term sustainability.

Tip: Regular maintenance and performance reviews maximize the benefits of eco-friendly refrigeration systems.