How Copper Fin Heat Exchangers Revolutionize Cooling in 2025

Global temperatures continue to rise, creating unprecedented cooling challenges. Data centers, for instance, consume about 1% of global electricity today, with projections suggesting an increase to 8% by 2030. This surge, driven by AI workloads and hyperscale data centers, demands innovative solutions. The copper fin heat exchanger meets this need, offering unmatched energy efficiency and sustainability for the future of cooling.

Key Takeaways

- Copper fin heat exchangers move heat quickly, cooling things faster. This helps use less energy and lowers costs to run them.

- These exchangers are strong and don’t rust easily, so they work well in tough places. They last a long time, so you don’t need to replace them often, saving money over time.

- Using copper fin heat exchangers helps the planet. They save energy and are smaller, which is better for the environment. They are great for homes and businesses.

The Challenges of Summer Cooling

Rising Global Temperatures and Energy Demands

I have observed that rising global temperatures are reshaping how we approach cooling. Urban areas face increased heat exposure due to global warming and urban expansion. This phenomenon, often referred to as the "urban heat island effect," amplifies the need for efficient cooling systems. Unfortunately, not everyone has equal access to air conditioning. Studies show that hospitalizations rise by 15% during hot weather in areas with limited AC access. Additionally, Black, Hispanic, and Latino Americans are less likely to own air conditioning units compared to other racial groups, highlighting disparities in cooling accessibility.

Energy consumption during summer months also tells a compelling story. In California, cooling accounted for over 16% of electricity use during a particularly hot summer in 2020, nearly double the share from 2019. Meanwhile, in India, cooling only represented 3% of electricity use in 2019, despite much higher average temperatures. These figures reveal significant regional disparities in energy consumption for cooling. Projections to 2050 suggest that these inequalities will persist, with some regions consuming far more energy for cooling than others.

| Metric | Observation |

|---|---|

| Cooling Degree Days (CDD) | General increase observed over the past two decades across various countries. |

| Energy Demand in Vietnam | More than doubled in the first decade of the 21st century due to population growth. |

| Temperature Trend | Countries in the tropical belt show a trend of 15 to 25 °C-year/year in cooling demand. |

These trends underscore the urgent need for innovative cooling technologies like the Copper Fin Heat Exchanger, which can address rising energy demands while maintaining efficiency.

Limitations of Traditional Cooling Systems

Traditional cooling systems struggle to keep up with modern demands. I have seen how these systems consume excessive energy, especially in high-density environments like data centers. In fact, traditional cooling methods can use up to 40% of a data center's total energy. This inefficiency not only increases operational costs but also contributes to a larger environmental footprint.

Traditional air-cooled infrastructure often fails to manage heat effectively in densely packed hardware environments. Overheating becomes a common issue, particularly with AI and high-performance computing applications that generate more heat than traditional workloads. As a result, energy consumption rises, and operational costs soar. These limitations make it clear that we need advanced solutions to meet the cooling challenges of today and tomorrow.

Note: The Copper Fin Heat Exchanger offers a game-changing alternative to traditional systems. Its superior thermal conductivity and energy efficiency make it an ideal choice for addressing these challenges.

Understanding Copper Fin Heat Exchangers

What Are Copper Fin Heat Exchangers?

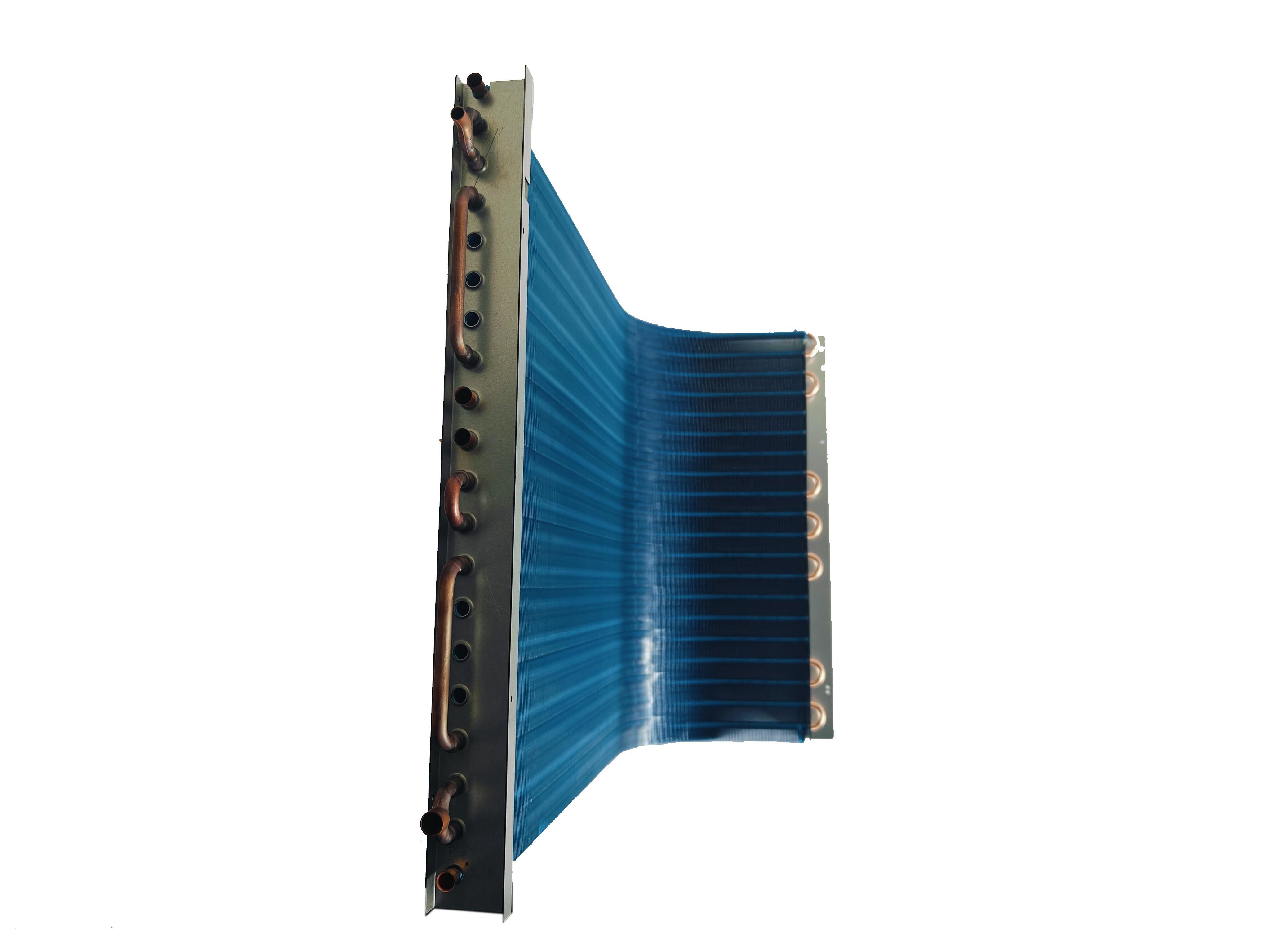

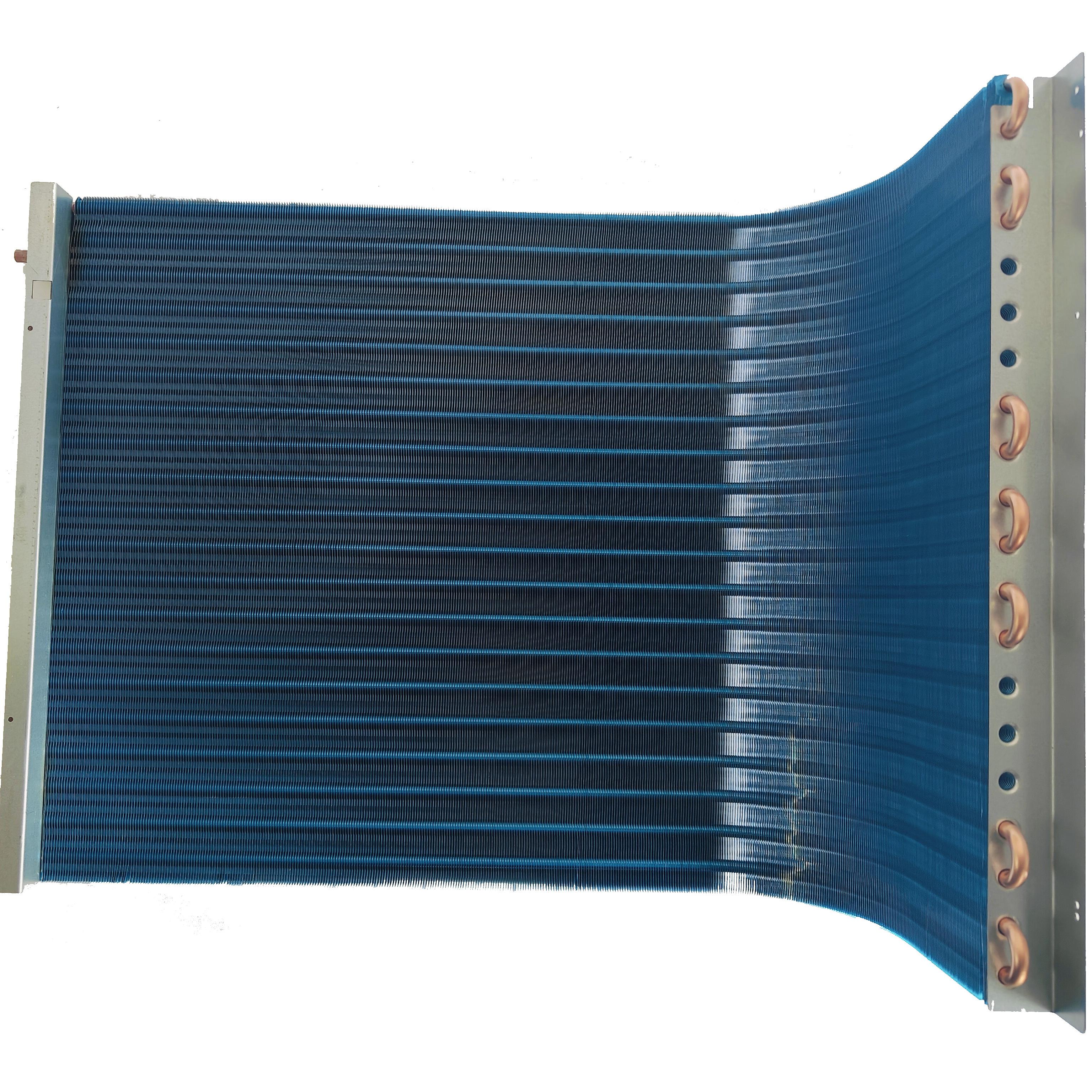

I often describe copper fin heat exchangers as the backbone of modern cooling systems. These devices transfer heat efficiently by using copper tubes and fins to maximize thermal conductivity. The copper fins increase the surface area for heat exchange, allowing for rapid cooling even in extreme conditions. This design makes them ideal for applications requiring high performance, such as air conditioning, refrigeration, and industrial cooling.

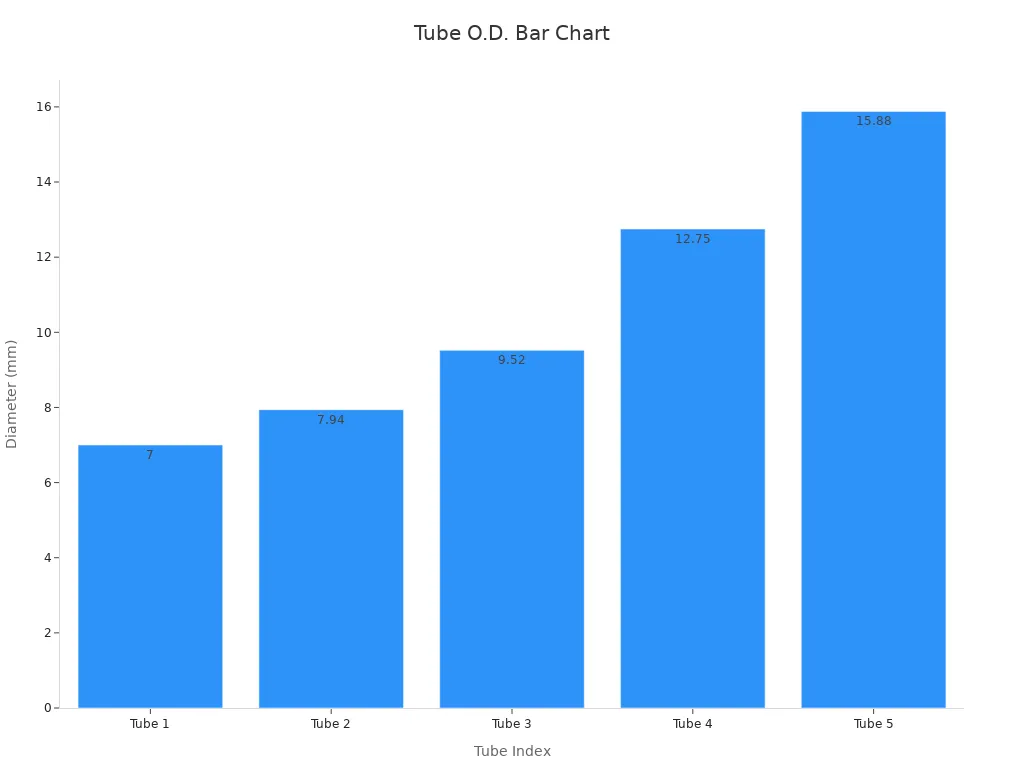

The technical specifications of copper fin heat exchangers highlight their versatility. For instance, they use materials like copper tube aluminum fins and galvanized plates, ensuring durability and resistance to corrosion. The tube outer diameters range from 7mm to 15.88mm, accommodating various cooling needs. Additionally, the fins come in multiple types, including hydroponic, flat, and louvered, with fin spacing adjustable between 1.1mm and 5.8mm. These features make copper fin heat exchangers adaptable to diverse environments and requirements.

| Specification | Details |

|---|---|

| Product Name | 316 Stainless Steel Aluminium Fin |

| Materials | Copper tube aluminum fin, galvanized plate |

| Tube O.D. | 7mm, 7.94mm, 9.52mm, 12.75mm, 15.88mm |

| Fin Type | Hydroponic fin, bare fin, flat fin, window fin, louver fin, smooth sine wave fin |

| Fin Space | 1.1mm - 5.8mm |

| Pitch of Holes/Rows | 19.0512.7mm; 25.522mm; 2521.65mm; 31.7527.5mm; 38.1*33mm |

How Copper Fin Heat Exchangers Differ from Traditional Systems

I have observed that copper fin heat exchangers outperform traditional cooling systems in several ways. First, their superior thermal conductivity ensures faster and more efficient heat transfer. Copper, as a material, conducts heat better than aluminum or steel, which are commonly used in older systems. This efficiency reduces energy consumption and operational costs.

Second, copper fin heat exchangers offer greater durability. Their corrosion-resistant properties make them suitable for harsh environments, including areas with high humidity or salt exposure. Traditional systems often degrade quickly under such conditions, leading to frequent replacements and higher maintenance costs.

Finally, the design flexibility of copper fin heat exchangers sets them apart. With customizable tube diameters, fin types, and spacing, they can be tailored to specific applications. This adaptability ensures optimal performance across various industries, from residential air conditioning to industrial refrigeration.

These advantages make copper fin heat exchangers a game-changing solution for modern cooling challenges.

Why Copper Fin Heat Exchangers Are Game-Changing in 2025

Enhanced Thermal Conductivity and Cooling Efficiency

I have always been impressed by the superior thermal conductivity of copper, which makes it an ideal material for heat exchangers. Copper boasts a thermal conductivity of approximately 401 W/m·K, far surpassing materials like stainless steel, which has a conductivity of less than 20 W/m·K. This remarkable property allows copper fin heat exchangers to transfer heat rapidly, ensuring efficient cooling even in demanding environments.

The design of these heat exchangers further enhances their performance. By incorporating copper fins, the surface area for heat exchange increases significantly. This design ensures that heat dissipates quickly, reducing the workload on HVAC systems. As a result, energy consumption decreases, and maintenance needs are minimized. I have seen firsthand how this efficiency translates to lower operational costs and improved system reliability.

Durability and Corrosion Resistance

Durability is another standout feature of copper fin heat exchangers. Copper's natural resistance to corrosion makes it a reliable choice for long-term use, even in harsh conditions. For instance, copper-nickel alloys have proven their effectiveness in marine applications, where they resist biofouling and microbial slime buildup. This same robustness applies to heat exchangers, ensuring they perform consistently over time.

To further enhance their durability, many copper components undergo protective treatments. For example, duplex tubes that combine copper with titanium offer exceptional resistance to corrosion. These advancements ensure that copper fin heat exchangers can withstand high temperatures and corrosive fluids, making them suitable for a wide range of applications. Compliance with standards like ASTM B154 and ISO 6509 guarantees that these materials meet rigorous safety and performance criteria.

Eco-Friendly and Energy-Saving Features

In 2025, sustainability is more important than ever, and copper fin heat exchangers excel in this area. By reducing the diameter of copper tubes, manufacturers have improved heat transfer efficiency while creating smaller, lighter coils. These innovations lead to significant energy savings in air-conditioning and refrigeration systems. Smaller coils also reduce the overall footprint of the equipment, making it easier to handle and install.

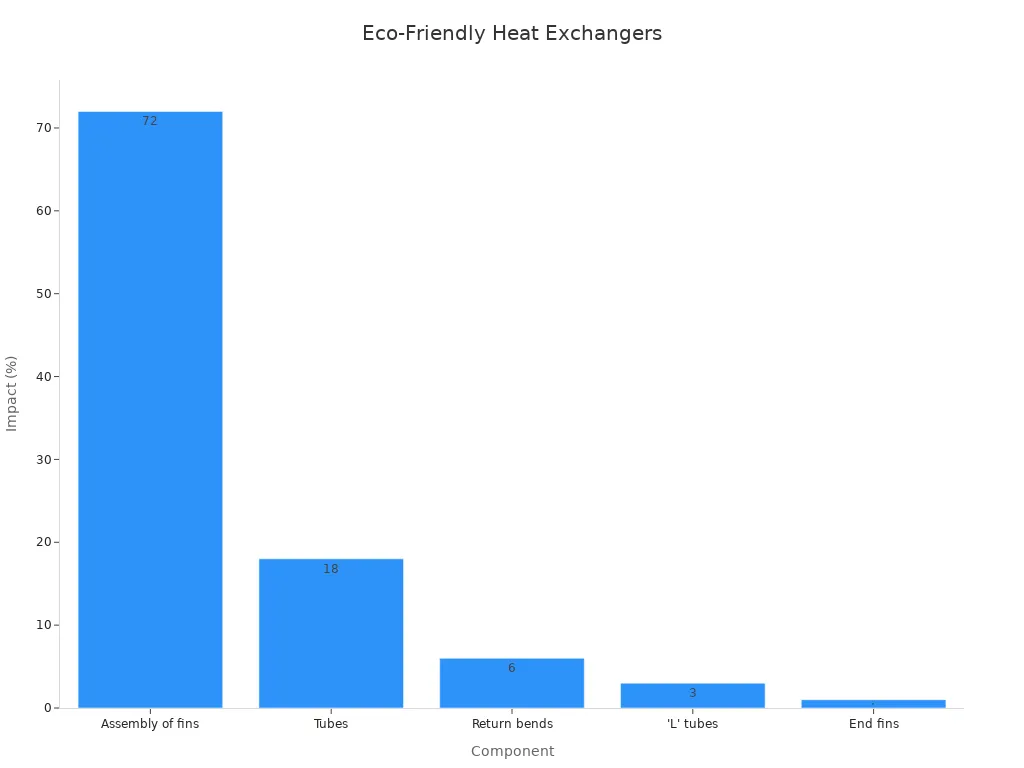

The environmental benefits extend beyond energy efficiency. A detailed analysis of the components used in copper fin heat exchangers reveals their minimal impact on global warming potential (GWP). For instance, the assembly of fins contributes 72% to the overall impact, while tubes account for only 18%. This balance highlights the eco-friendly nature of these systems.

I believe that adopting copper fin heat exchangers is a step toward a greener future. Their energy-saving capabilities and reduced environmental impact make them a smart choice for both residential and industrial applications.

Real-World Applications of Copper Fin Heat Exchangers

Senjun's Household Air Conditioner Condenser: A Case Study

I often highlight Senjun's Household Air Conditioner Condenser as a prime example of how copper fin heat exchangers excel in real-world applications. This condenser, crafted with Bundy tubes coated in copper, showcases the remarkable efficiency of copper in heat transfer. Its ability to cool a sunlit living room from 35°C to 26°C in just 15 minutes demonstrates its rapid heat dissipation capabilities. This performance is critical in regions where summer temperatures exceed 40°C.

The condenser's durability also stands out. Its cathodic electrophoresis treatment ensures resistance to corrosion, even in humid climates. I have seen how this feature enhances its lifespan, making it a reliable choice for households. Additionally, its low-noise operation, with sound levels below 40 decibels, ensures comfort without disruption. This makes it ideal for families and light sleepers.

Industries and Scenarios Benefiting from Copper Fin Heat Exchangers

Copper fin heat exchangers find applications across diverse industries. In data centers, they efficiently manage heat generated by high-performance computing systems, reducing energy consumption. I have observed their use in refrigeration systems, where their superior thermal conductivity ensures consistent cooling for perishable goods.

In humid climates, these heat exchangers excel in dehumidification, maintaining comfortable indoor environments. Their corrosion resistance makes them suitable for marine and coastal applications. From residential air conditioning to industrial refrigeration, the versatility of copper fin heat exchangers addresses a wide range of cooling challenges.

I believe copper fin heat exchangers represent the future of cooling. Products like Senjun's Household Air Conditioner Condenser showcase how this technology addresses rising temperatures and energy demands with unmatched efficiency and sustainability. By adopting these innovative solutions, we can achieve effective cooling while contributing to a greener planet. Explore the transformative potential of copper fin heat exchangers today.

FAQ

What makes copper fin heat exchangers more efficient than traditional systems?

Copper's superior thermal conductivity ensures faster heat transfer. Its fins increase surface area, enhancing cooling efficiency. This design reduces energy consumption and operational costs, making it highly efficient.

How does Senjun's Household Air Conditioner Condenser handle extreme climates?

Its copper-coated Bundy tubes and cathodic electrophoresis treatment resist corrosion. It cools rooms rapidly, even in 40°C heat, and performs well in humid conditions, ensuring long-lasting reliability.

Are copper fin heat exchangers environmentally friendly?

Yes! Their energy-saving design reduces carbon footprints. Smaller, lighter coils minimize material usage. Copper's recyclability further enhances sustainability, making these exchangers an eco-conscious cooling solution. 🌱