Emerging Refrigeration Technologies Shaping 2025

Refrigeration plays a critical role in solving modern challenges. You rely on these systems to preserve food, maintain healthcare supplies, and support industrial processes. Advances in R & D AND MANUFACTURING New technologies for refrigeration products are driving sustainability. These innovations reduce environmental impact, improve energy efficiency, and enhance operational reliability across industries.

Eco-Friendly Refrigerants

Transition to Low-GWP Refrigerants (e.g., R-32, R-454B)

You’ve likely heard about the shift toward low-GWP (Global Warming Potential) refrigerants like R-32 and R-454B. These refrigerants are designed to minimize their impact on the environment. R-32, for example, has a GWP that is significantly lower than traditional refrigerants like R-410A. It also improves energy efficiency, which helps reduce electricity consumption. R-454B, another promising option, offers even lower GWP levels while maintaining excellent cooling performance. By adopting these refrigerants, you contribute to reducing greenhouse gas emissions and combating climate change.

Environmental Benefits of Natural Refrigerants

Natural refrigerants, such as ammonia (NH3), carbon dioxide (CO2), and hydrocarbons, provide a sustainable alternative to synthetic options. These substances occur naturally in the environment, which makes them less harmful when released. For instance, CO2 has a GWP of 1, making it one of the most eco-friendly choices. Ammonia, while requiring careful handling, offers exceptional energy efficiency. Hydrocarbons like propane (R-290) are also gaining popularity due to their low environmental impact. By using natural refrigerants, you help protect ecosystems and reduce the carbon footprint of refrigeration systems.

Regulatory Drivers and Industry Adoption

Governments and international organizations are pushing for the adoption of eco-friendly refrigerants. Regulations like the Kigali Amendment to the Montreal Protocol aim to phase down high-GWP refrigerants globally. In response, industries are accelerating the transition to compliant technologies. You’ll notice that manufacturers are redesigning systems to accommodate low-GWP and natural refrigerants. This shift not only meets regulatory requirements but also aligns with consumer demand for sustainable solutions. By staying informed, you can make choices that support both the environment and regulatory compliance.

Energy Efficiency

Variable Speed Compressors for Optimized Performance

You can significantly improve energy efficiency by using variable speed compressors. These compressors adjust their speed based on the cooling demand, unlike traditional models that operate at a fixed speed. This flexibility reduces energy waste during low-demand periods. For example, when the temperature stabilizes, the compressor slows down, consuming less electricity. This not only lowers your energy bills but also extends the lifespan of the equipment. Many modern refrigeration systems now include variable speed technology, making it easier for you to adopt this energy-saving solution.

Tip: Look for systems with inverter technology. It enhances the performance of variable speed compressors and ensures smoother operation.

Heat Recovery Systems for Energy Reuse

Heat recovery systems capture waste heat generated during the refrigeration process and reuse it for other purposes. You can use this recovered heat to warm water, heat buildings, or support other industrial processes. This approach reduces the need for additional energy sources, cutting costs and lowering your carbon footprint. For instance, in commercial kitchens, recovered heat can preheat water for dishwashing. By integrating heat recovery into your system, you maximize energy utilization and contribute to a more sustainable operation.

Hybrid Refrigeration Systems Combining Technologies

Hybrid refrigeration systems combine multiple technologies to achieve optimal performance. These systems often integrate traditional cooling methods with advanced features like thermal storage or renewable energy sources. You might see setups that use solar power during the day and switch to grid electricity at night. This dual approach ensures consistent cooling while reducing dependency on non-renewable energy. Hybrid systems are ideal for applications requiring high reliability and efficiency, such as food storage or medical facilities.

Note: Hybrid systems offer flexibility. You can customize them to meet specific energy and operational needs.

Smart and Automated Technologies

IoT Integration for Real-Time Monitoring

You can now monitor refrigeration systems in real time with IoT (Internet of Things) technology. Sensors collect data on temperature, humidity, and energy usage. This data is sent to a centralized platform, allowing you to track performance from anywhere. For example, if a temperature fluctuation occurs, the system alerts you immediately. This helps you prevent spoilage and maintain efficiency.

Tip: Choose IoT-enabled systems with mobile app support. This makes it easier to access data on the go.

IoT also improves energy management. By analyzing usage patterns, you can identify areas to optimize. This reduces waste and lowers operational costs.

Predictive Maintenance with AI and Machine Learning

AI and machine learning take maintenance to the next level. These technologies analyze system data to predict potential issues before they occur. For instance, if a compressor shows signs of wear, the system notifies you to schedule maintenance. This prevents costly breakdowns and extends equipment life.

Predictive maintenance also reduces downtime. You can plan repairs during non-peak hours, ensuring uninterrupted operations.

Note: Regular updates to AI algorithms improve accuracy. Always keep your system software up to date.

Enhanced System Control Through Automation

Automation gives you precise control over refrigeration systems. Automated controls adjust settings based on real-time conditions. For example, during low-demand periods, the system reduces cooling output to save energy.

You can also program systems to follow specific schedules. This ensures consistent performance without manual intervention. Automation simplifies operations and enhances reliability.

Emoji Insight: ⚙️ Automation = Efficiency + Convenience!

Modular and Customizable Solutions

Scalable Systems for Diverse Applications

You need refrigeration systems that adapt to your specific needs. Scalable systems allow you to expand or reduce capacity based on demand. For example, a small business can start with a compact unit and add more modules as operations grow. This flexibility ensures you only invest in what you need at the moment.

Scalable systems work well in industries like food storage, retail, and healthcare. You can adjust the system to handle seasonal changes or increased production. This adaptability helps you save money and avoid overloading your equipment.

Tip: Choose systems with modular components. They make upgrades and maintenance easier.

Flexible Designs for Space and Energy Optimization

Space constraints can limit your options. Flexible refrigeration designs solve this problem by offering compact and energy-efficient solutions. You can find systems that fit into tight spaces without compromising performance.

For instance, under-counter units work well in small kitchens, while vertical systems maximize storage in warehouses. These designs also focus on energy optimization. By using advanced insulation and efficient cooling mechanisms, they reduce energy consumption.

Emoji Insight: 🏢 Small space? No problem! Flexible designs have you covered.

Cost-Effective Customization for Specific Needs

Customizing refrigeration systems doesn’t have to break the bank. Manufacturers now offer cost-effective options tailored to your requirements. You can select features like temperature zones, shelving configurations, or energy-saving modes.

This approach ensures you get a system that meets your needs without unnecessary extras. For example, a pharmaceutical company might need precise temperature control, while a grocery store prioritizes storage capacity.

Note: Customization improves efficiency and reduces long-term costs. Always evaluate your needs before making a decision.

Industry-Specific Innovations

Advanced Refrigeration for Food Safety and Preservation

You rely on refrigeration to keep food fresh and safe. Advanced systems now use precise temperature control to prevent spoilage and maintain quality. For example, blast chillers rapidly cool food to inhibit bacterial growth. These systems are ideal for restaurants, grocery stores, and food processing plants.

Humidity control is another innovation. It helps preserve the texture and flavor of fresh produce. You can store fruits and vegetables longer without losing their nutritional value. By adopting these technologies, you reduce food waste and improve safety standards.

Tip: Look for systems with multi-zone cooling. They allow you to store different types of food at their optimal temperatures.

Cutting-Edge Solutions for Healthcare and Pharmaceuticals

Refrigeration plays a critical role in healthcare. You need reliable systems to store vaccines, medicines, and lab samples. Modern pharmaceutical refrigeration units offer ultra-low temperatures, ensuring the integrity of sensitive products.

Some systems now include backup power options. These features protect your inventory during power outages. Advanced monitoring systems also alert you to temperature fluctuations. This ensures compliance with strict healthcare regulations.

Emoji Insight: 🩺 Reliable refrigeration = Safer healthcare solutions!

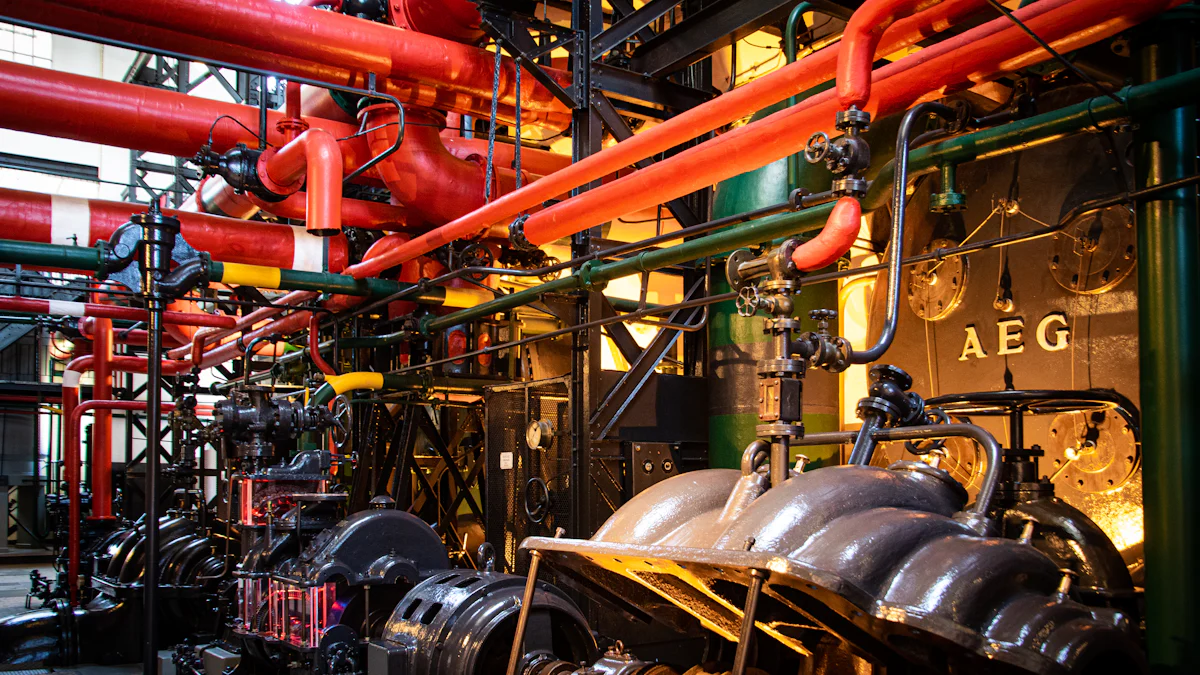

Specialized Systems for Industrial and Commercial Applications

Industrial and commercial sectors require robust refrigeration systems. You might need large-scale units for warehouses or compact designs for retail spaces. Modern systems now integrate R & D AND MANUFACTURING New technologies for refrigeration products to enhance performance.

For example, cold storage facilities use energy-efficient designs to lower costs. Commercial units often include customizable shelving for better space utilization. These innovations help you meet operational demands while saving energy.

Note: Choose systems designed for your industry. This ensures efficiency and long-term reliability.

R & D AND MANUFACTURING New Technologies for Refrigeration Products

Innovations in Thermal Insulation and Cooling Efficiency

You can now benefit from advanced thermal insulation materials that improve cooling efficiency. These materials reduce heat transfer, keeping the cold air inside and external heat out. For example, vacuum-insulated panels (VIPs) offer superior insulation compared to traditional foam. VIPs are thinner and lighter, making them ideal for compact refrigeration systems.

Enhanced cooling mechanisms also play a role. Technologies like microchannel heat exchangers improve heat transfer, reducing energy consumption. These innovations ensure your refrigeration systems operate efficiently while lowering operational costs.

Tip: Look for systems with advanced insulation to save energy and maintain consistent cooling performance.

Decarbonization and Heat Pump Development

Decarbonization is transforming refrigeration. You can now choose systems designed to minimize carbon emissions. Heat pumps are a key part of this shift. They use renewable energy sources like solar or geothermal to provide cooling and heating. This dual functionality reduces reliance on fossil fuels.

Modern heat pumps also feature improved refrigerants with low GWP. These systems align with global sustainability goals and help you reduce your environmental impact. By adopting decarbonized technologies, you contribute to a greener future.

Emoji Insight: 🌍 Decarbonization = Cleaner air and a healthier planet!

AI Hybrid Cooling Technology and Future Trends

Artificial intelligence is revolutionizing refrigeration. AI hybrid cooling systems combine traditional methods with smart algorithms. These systems analyze data to optimize performance. For instance, they adjust cooling levels based on usage patterns, saving energy.

Future trends include self-learning systems that adapt to changing conditions. You can expect refrigeration units that predict demand and adjust automatically. These advancements improve efficiency and reduce waste.

Note: AI-driven systems are the future. Stay ahead by exploring these cutting-edge solutions.

The refrigeration industry is evolving rapidly. You see eco-friendly refrigerants, energy-efficient designs, and smart technologies reshaping the landscape. These innovations tackle sustainability challenges while improving operational efficiency.

Key Insight: As 2025 approaches, adopting these advancements ensures you stay ahead. They benefit industries, reduce environmental impact, and create a sustainable future. 🌱