0102030405

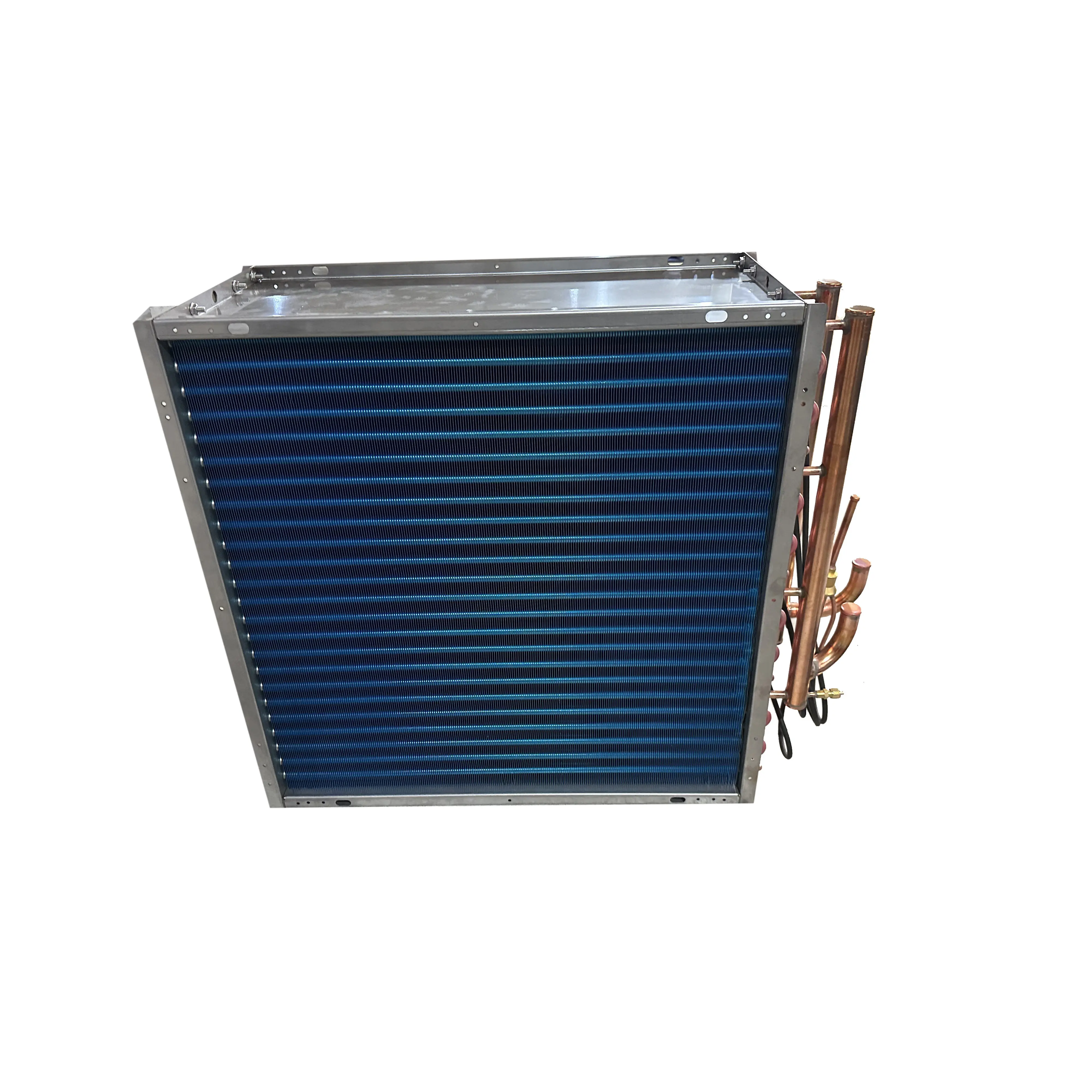

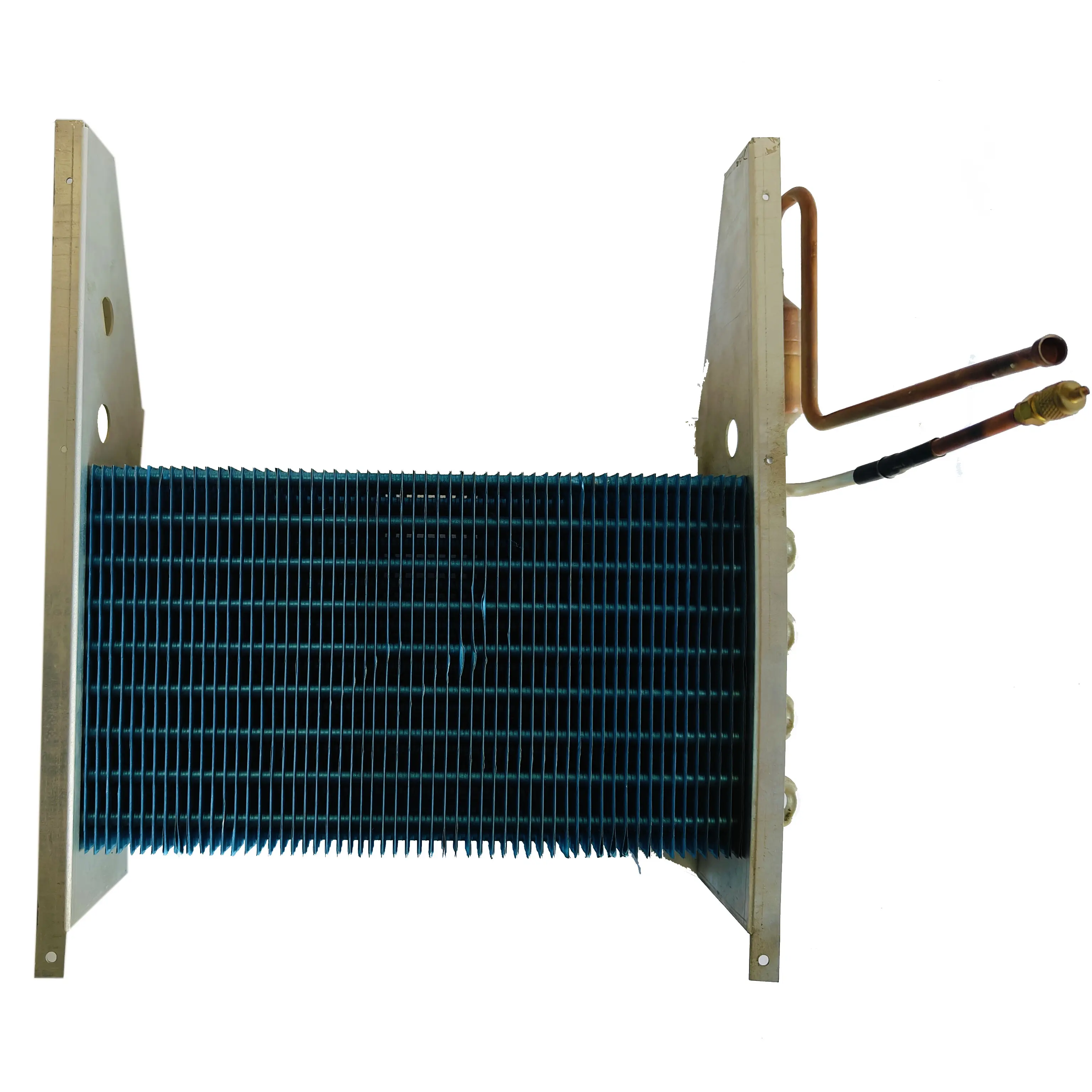

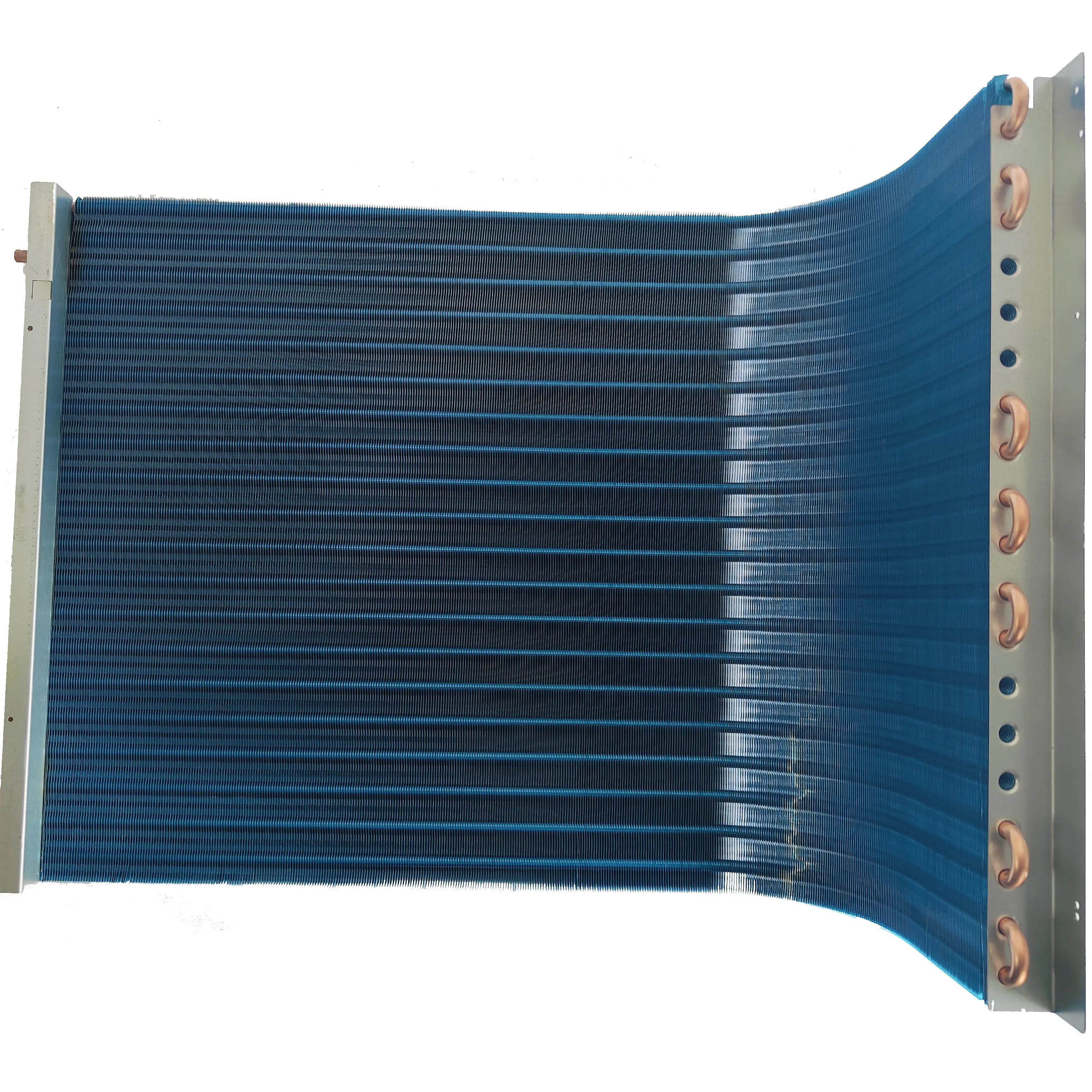

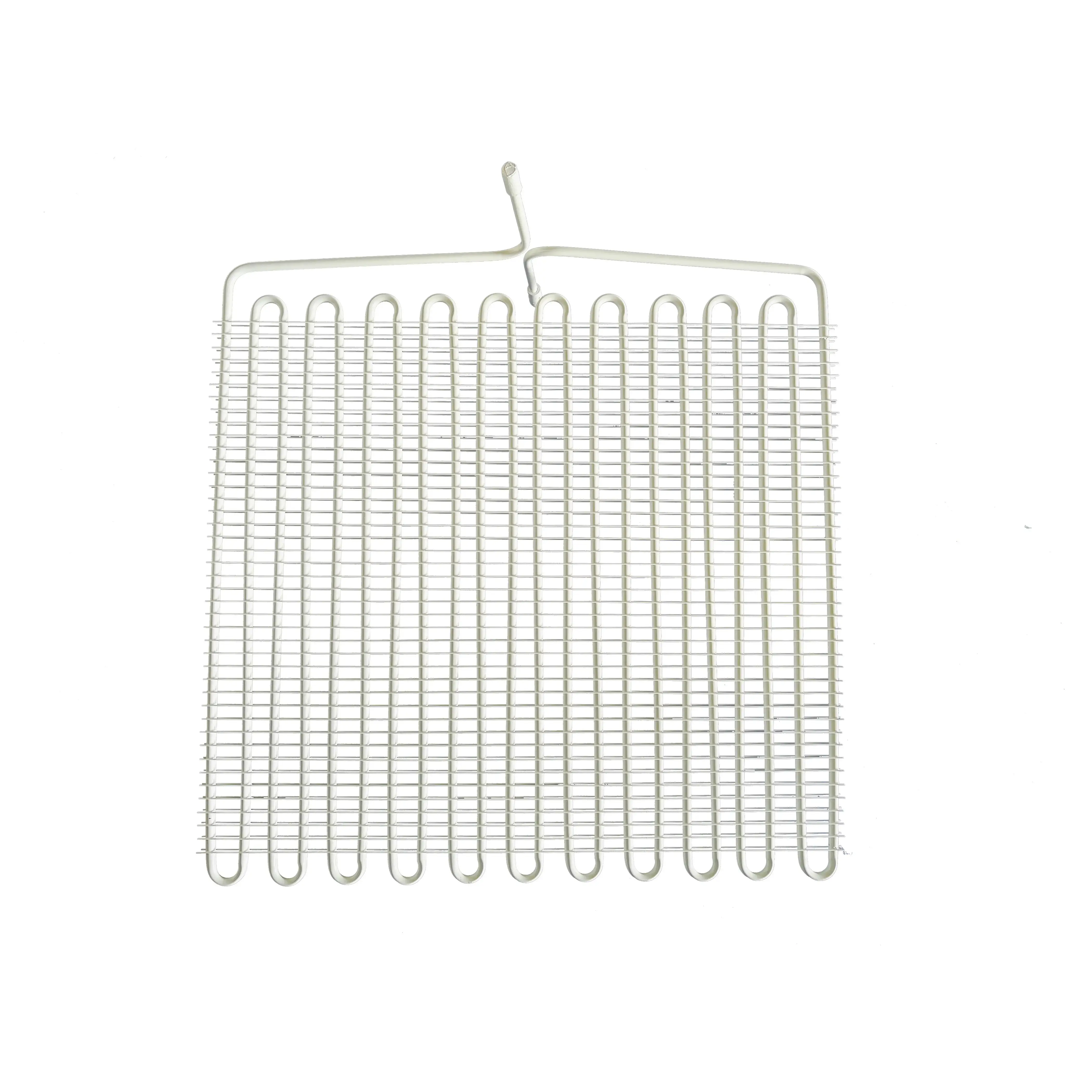

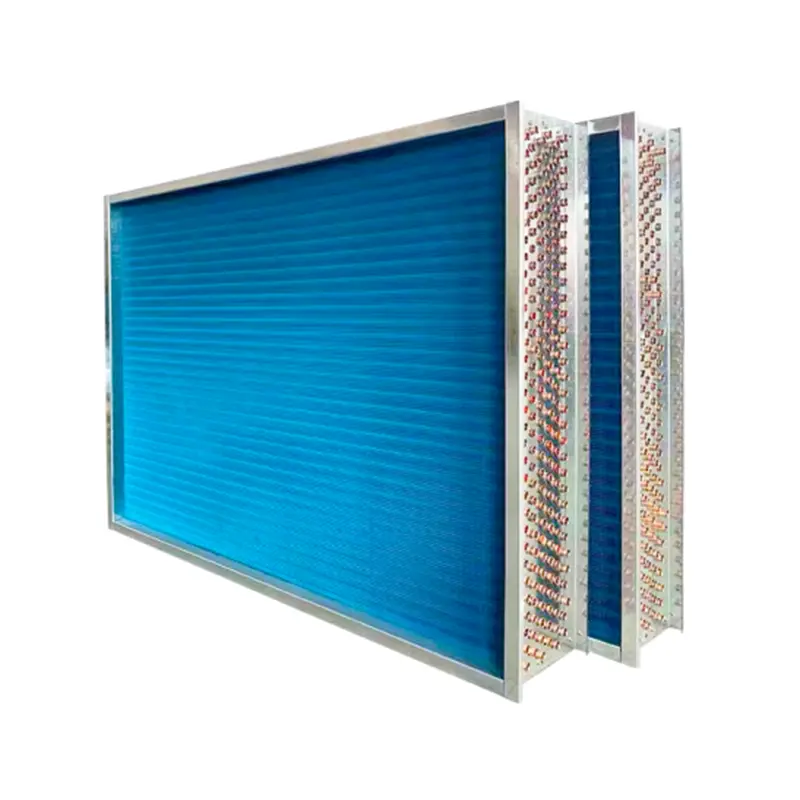

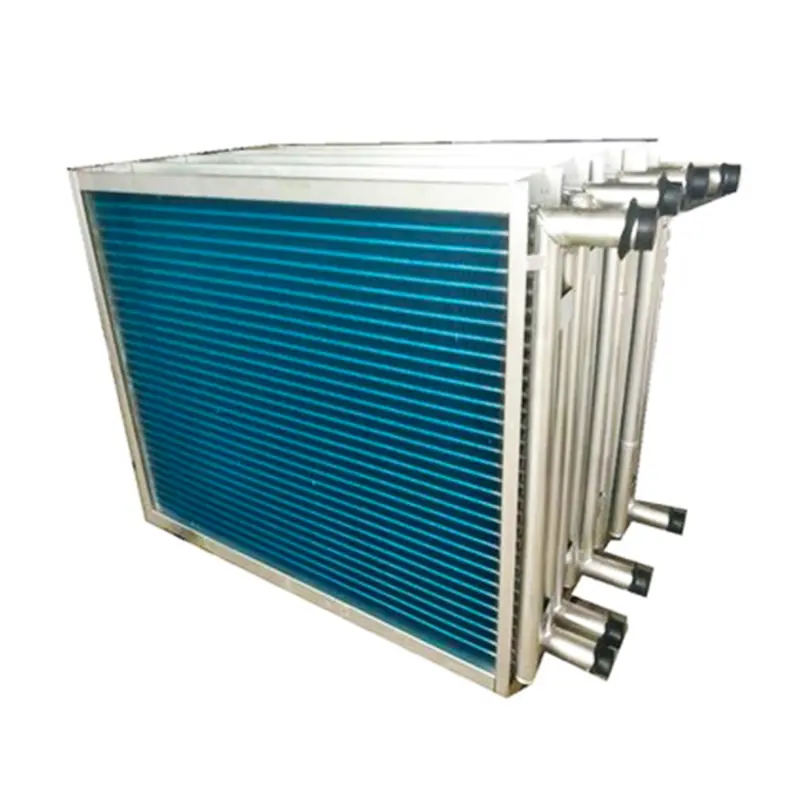

Industrial Chiller Heat Exchanger for Efficient Cooling Solutions

Product DisplaySENJUN

PRODUCT DESCRIPTIONSENJUN

The design of four air vents allows the radiator to obtain a more sufficient supply of cold air, and the heat dissipation efficiency is higher than that of a single air vent or double air vent radiator. The four air vents can introduce cold air from different directions and cover the heat dissipation fins more comprehensively, thereby taking away the heat faster. Due to its strong heat dissipation capacity, the four-outlet air-cooled condensing radiator can be applied to a variety of heating equipment of different powers and sizes. Whether it is small computer hardware or larger industrial electronic equipment, as long as the heat generated is within the heat dissipation capacity of the radiator, this radiator can be used for heat dissipation.

-

1. Plastic processing industry:During plastic extrusion, injection molding and other processing processes, molds and equipment need to be cooled to ensure the quality and production efficiency of plastic products. The industrial chiller heat exchanger circulates cold water into the mold and equipment, absorbs heat and then returns to the chiller for cooling, effectively controlling the processing temperature and improving the accuracy and surface quality of plastic products.

-

2.Chemical production industry:Many reaction processes in chemical production need to be carried out under specific temperature conditions. Industrial chiller heat exchangers can provide precise cooling control for reactors, condensers and other equipment. For example, in the production process of synthetic ammonia, the chiller heat exchanger is used to cool the high-temperature gas at the outlet of the synthesis tower to reduce its temperature to a suitable range for subsequent separation and treatment processes.

-

3. Pharmaceutical industry:The pharmaceutical industry has extremely high requirements for production environment and process temperature control. All aspects from drug synthesis, fermentation, crystallization to freeze-drying require precise temperature control. Industrial chiller heat exchangers provide stable low-temperature cooling conditions for pharmaceutical equipment and processes, ensuring that the active ingredients of drugs are not destroyed and ensuring the stability of drug quality and efficacy. For example, in the fermentation process of biopharmaceuticals such as antibiotics and vaccines, heat exchangers are used to control the temperature of the fermentation tank and create a suitable environment for the growth and metabolism of microorganisms.

-

4.Electronics manufacturing industry:During the production and manufacturing process of electronic components, equipment and working environment need to be cooled to prevent electronic components from being damaged due to overheating and affecting product quality and production efficiency. Industrial chiller heat exchangers are widely used in chip manufacturing, circuit board welding and other processes in the electronics manufacturing industry to provide efficient cooling for electronic production equipment.