0102030405

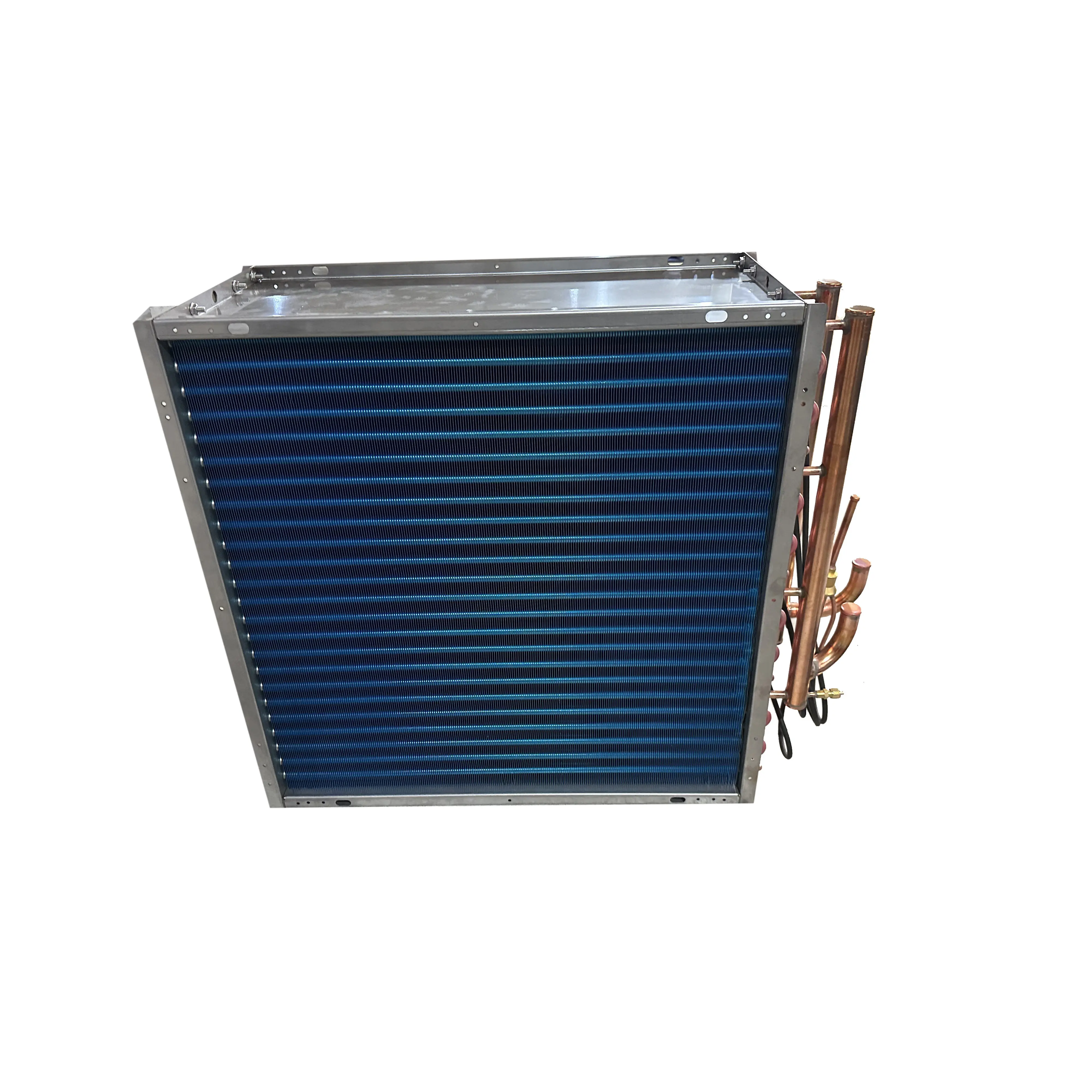

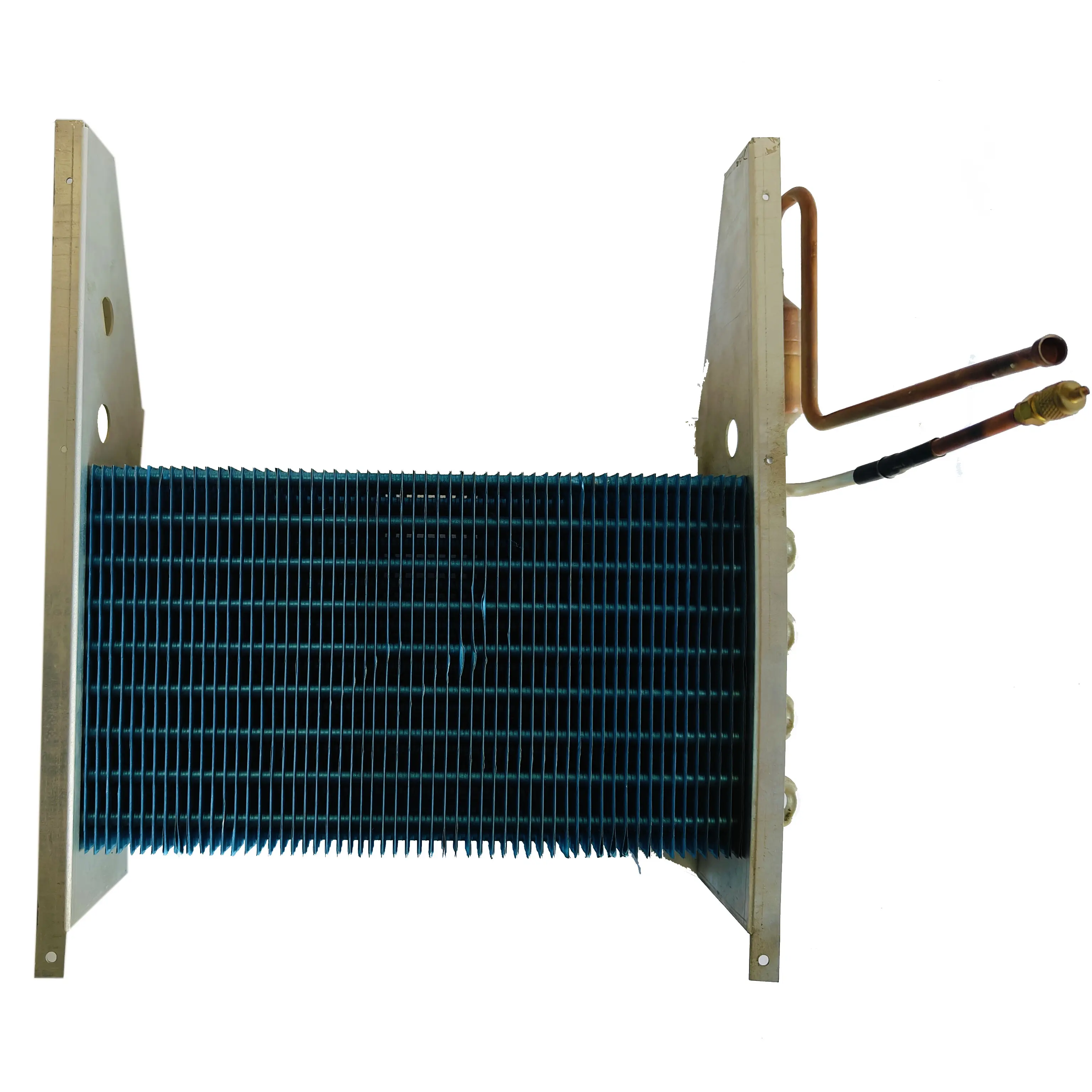

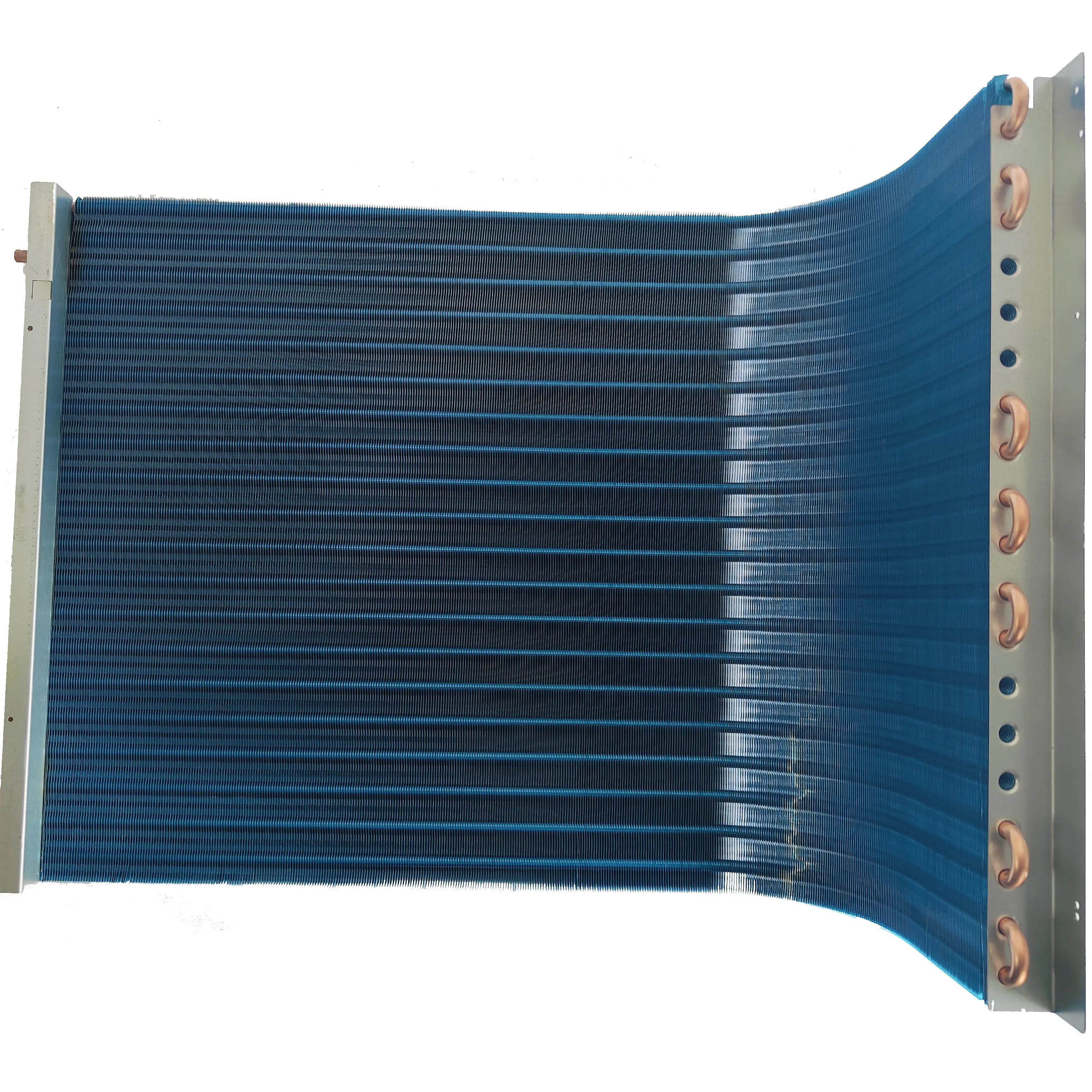

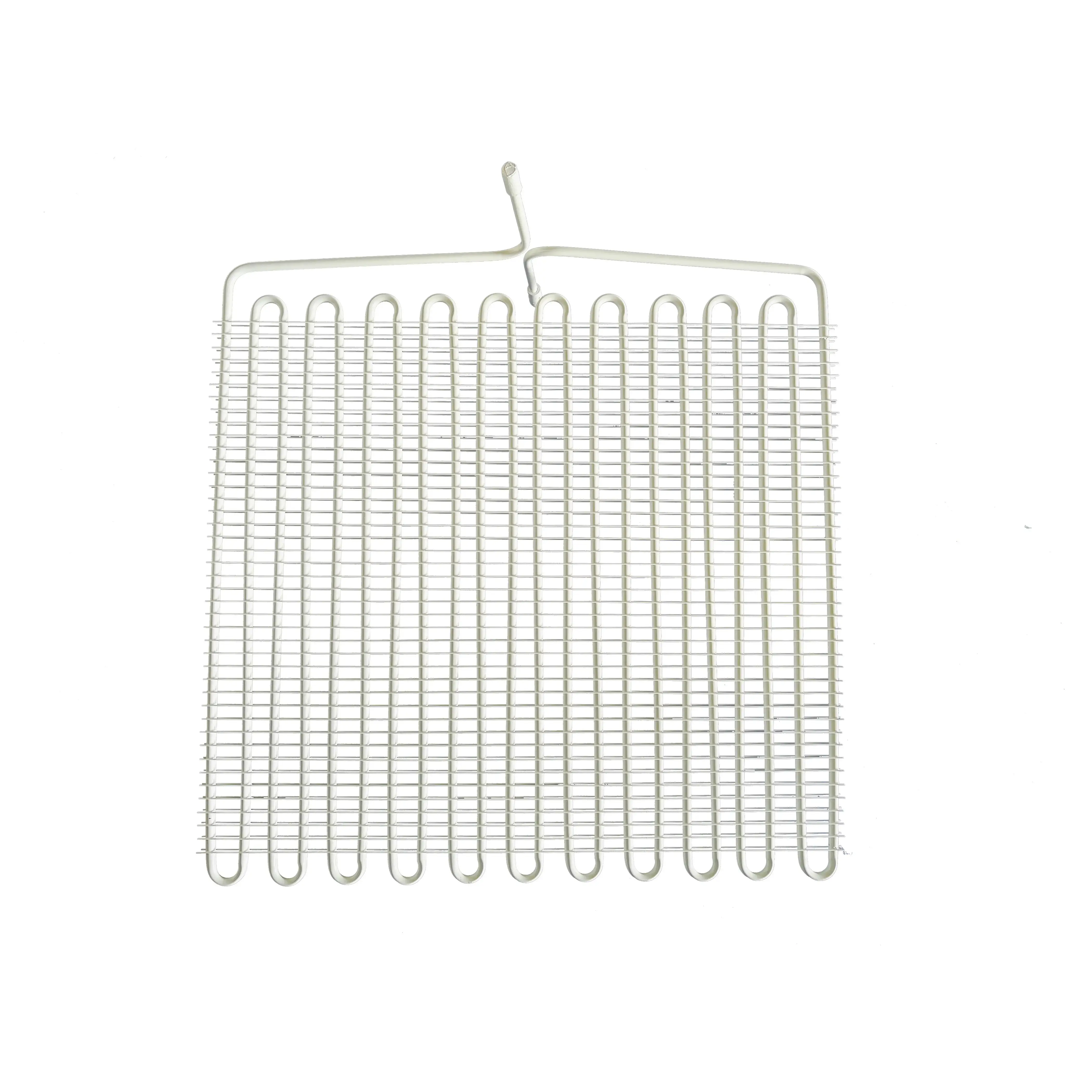

Cold Storage Heat Exchanger for Efficient Air-Cooled Units

Product DisplaySENJUN

PRODUCT DESCRIPTIONSENJUN

During the refrigeration process, the refrigerant absorbs heat from the air in the cold storage in the evaporator and changes from liquid to gas. Since the fins of the evaporator increase the contact area with the air, heat can be quickly absorbed by the refrigerant. The gaseous refrigerant is then compressed by the compressor into high-temperature and high-pressure gas and enters the condenser. In the condenser, through the action of the fan, the outside air quickly flows through the fins of the condenser. The refrigerant transfers heat to the air and returns to a liquid state, completing a refrigeration cycle. The following are common application scenarios;

-

1. Food cold chain industryCentral kitchen cold storage for chain catering companiesThe central kitchen of a chain restaurant company usually has a large cold storage for storing ingredients. The air-cooled unit cold storage heat exchanger plays a key role here. Take a hamburger chain as an example. The bread dough, patties, vegetables and other ingredients stored in its cold storage all need a suitable temperature environment. The heat exchanger can accurately control the temperature within an appropriate range. For example, the temperature in the vegetable storage area is controlled at 2 - 4°C, and the temperature in the meat patty storage area is controlled at - 10°C - - 15°C, ensuring the freshness and safety of the ingredients. The restaurant provides a stable supply of ingredients.

-

2. Pharmaceutical industryRaw material and finished product warehouses for pharmaceutical manufacturersIn pharmaceutical manufacturing enterprises, the air-cooling unit cold storage heat exchanger is an important equipment to ensure the quality of pharmaceuticals. For some temperature-sensitive raw materials, such as biologically active ingredients, vaccine antigens, etc., the cold storage temperature needs to be accurately controlled at 2-8°C. The heat exchanger can effectively maintain this temperature range and prevent the raw materials from deteriorating. Finished drugs, such as injections, capsules, etc., also need to be stored in a suitable temperature environment to ensure the efficacy and stability of the drugs.