In industrial applications, the importance of an Air Compressor Filter Dryer cannot be overstated. A recent study found that 80% of system failures are due to contaminants. This highlights the necessity of having an efficient filtration system. The right filter dryer significantly reduces water vapor and particulates, ensuring compressed air quality.

When choosing an Air Compressor Filter Dryer, consider efficiency and operational costs. According to market research, effective filter dryers can improve equipment lifespan by up to 30%. However, not all filter dryers are created equal. Some may fail to meet specific industry standards, leading to increased maintenance costs.

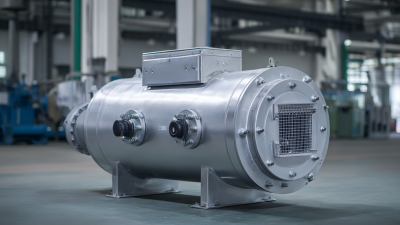

Understanding the various types of Air Compressor Filter Dryers is essential for optimal performance. Mistakes in selection can result in inefficiencies. A thorough evaluation of your specific needs can prevent these issues. This article explores the top five filter dryers you must know to enhance your compressed air systems.

Air compressor filter dryers play a crucial role in maintaining the quality and efficiency of compressed air systems. They remove moisture, oil, and particulate contaminants. According to industry reports, up to 70% of compressor failures stem from poor air quality. Without proper filtration, equipment can break down more frequently. This leads to increased maintenance costs and longer downtime.

Investing in a good air compressor filter dryer is essential. Look for models capable of removing particles down to 0.01 microns. Many experts recommend double-checking specifications to ensure compatibility with your system. A dryer can save up to 50% on energy costs by reducing the workload on air compressors. This deserves careful consideration, especially for companies monitoring their operational expenses.

Tips: Regularly check and replace your filter elements. Ignoring this can lead to inefficiency. Monitor the dew point as well. A dew point above 38°F can indicate moisture issues. Ultimately, maintaining a clean and dry air supply is vital for prolonged equipment life. Regular assessments can help identify hidden inefficiencies.

Choosing the right filter dryer for your air compressor is crucial. Filter dryers remove moisture from compressed air. They prevent corrosion and damage in tools and equipment. When selecting a filter dryer, consider its efficiency. Some dryers can remove up to 99% of moisture. Efficiency can vary based on design and technology.

Another key feature is capacity. Ensure the dryer can handle your compressor's output. A dryer with inadequate capacity may lead to moisture issues. Pay attention to the filter's replaceability. A filter that requires frequent changes can become a hassle. Maintenance should be straightforward and not too time-consuming.

Don’t overlook the size of the unit. A compact design may fit better in a small workspace. Yet, ensure it doesn't compromise performance. Look for models that provide visual indicators for maintenance needs. These reminders can help maintain optimal functionality. Sometimes, these visual cues can be missed or ignored, leading to inefficiencies. Keep this in mind when making your choice.

When it comes to air compressor systems, filter dryers are essential. They remove moisture and contaminants from compressed air. According to industry reports, up to 70% of air compressor failures are due to moisture-related issues. Choosing the right filter dryer can drastically reduce these failures and enhance equipment lifespan.

The best air compressor filter dryers offer various features. Some models use a desiccant to effectively absorb moisture. Others utilize a coalescing filter to remove particulates. For instance, studies show that coalescing filters can achieve up to a 99% efficiency rate in removing oil aerosols. Yet, not all dryers are equal. Certain units may struggle under high temperature and humidity conditions. It’s important to assess your specific environment and needs.

Many professionals overlook maintenance needs. Even the best filter dryers need regular checks. Regularly replacing filter elements is crucial for optimal performance. Neglecting this can lead to reduced efficiency. Experts suggest that maintaining proper operational pressure can improve the system's overall energy usage by as much as 12%. Fine-tuning your filter dryer choice can lead to significant savings and better air quality.

Filter dryers are crucial for maintaining air quality in compressors. Proper installation is essential for optimal performance. Begin by ensuring the filter dryer matches the compressor specifications. Incorrect sizing can lead to poor performance and increased wear. Pay attention to connections and make them tight to prevent leaks.

Regular maintenance is equally important. Check the filter every few months. A clogged filter can increase pressure drop and reduce efficiency. Clean or replace filters as necessary. Ensure that the dryer is operating within its temperature and pressure limits. Overheating can cause damage that is costly to repair.

Don’t overlook the importance of visual checks. Look for signs of wear or corrosion. These can indicate underlying issues that need to be addressed. Document findings during inspections. This record can help in identifying patterns and planning future maintenance. Even small neglect can lead to bigger problems later. Stay proactive to ensure longevity.

Air compressor filter dryers play a key role in ensuring the integrity of compressed air systems. They remove moisture, contaminants, and oils. However, common issues can impede their performance. According to a recent industry report, nearly 30% of air compressor issues stem from inadequate filtration. A typical problem is the clogging of filters which leads to reduced airflow. When airflow decreases, the efficiency of the entire system is compromised.

Another prevalent issue is the formation of ice in the filter dryer. This often occurs during colder months. Ice can block airflow and damage the compressor. Regular maintenance is crucial. Inspecting filters monthly can prevent potential blockages. Additionally, replacing worn-out elements can enhance performance. Many operators overlook the importance of monitoring dew points. Failing to do so might lead to condensation in the air lines, resulting in costly equipment damage.

Finally, system leaks can pose significant problems. Reports suggest that even a small leak can waste up to 30% of compressed air. This is doubly concerning when considering the energy costs involved. Continuous monitoring and timely repairs can mitigate these issues. Realizing that filter dryers require proactive care is essential for maintaining a reliable compressed air system.