In the world of air compressors, the role of an Air Compressor Filter Dryer cannot be overstated. As John Smith, a renowned expert in the field, aptly puts it, “Choosing the right air compressor filter dryer can significantly impact your system's efficiency.” The advancement of technology introduces a variety of options for 2026. It becomes critical to understand what works best.

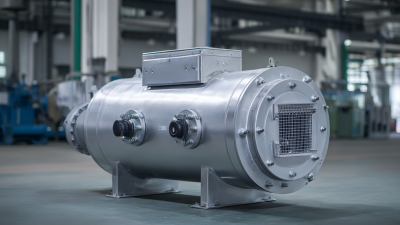

The market offers various types of Air Compressor Filter Dryers. Each model has unique features, tailored for different applications. Some are designed for high moisture environments, while others suit better for industrial use. However, not all products meet every requirement perfectly. Customers often face challenges when selecting the right one.

Investing in an Air Compressor Filter Dryer is not just about the initial cost. It involves assessing long-term efficiency and maintenance needs. It's essential to reflect on past purchasing decisions and learn from them. Choosing wisely means considering specific needs rather than just opting for popular choices.

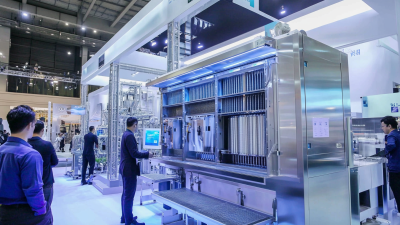

When it comes to air compressor filter dryers, 2026 presents many exciting options. A recent industry report suggests that the demand for effective air filtration systems is projected to grow by 5.5% annually. This growth highlights the importance of investing in reliable equipment. Choosing the right filter dryer can significantly improve efficiency and reduce maintenance costs.

Consider the desiccant filter dryers. These devices excel in removing moisture and contaminants. In environments where air quality is critical, they are often preferred. Based on studies, systems with lower dew points can enhance productivity by preventing corrosion in air tools. Yet, they may require regular replacement of desiccant materials, which can accumulate costs over time.

Tips for selecting a filter dryer: always check the specifications for flow rates. A mismatch can lead to inefficiencies. Additionally, look for energy-efficient models to reduce operational costs in the long run. Remember, while cheaper options might save initial costs, they could lead to higher maintenance and replacements down the line. Investing wisely is essential.

| Model | Type | Max Pressure (BAR) | Flow Rate (CFM) | Drying Capacity (L/h) | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | Refrigerated | 10 | 15 | 300 | 50 |

| Model B | Desiccant | 13 | 20 | 400 | 60 |

| Model C | Membrane | 8 | 10 | 200 | 30 |

| Model D | Centrifugal | 15 | 25 | 500 | 70 |

When selecting an air compressor filter dryer, a few key features stand out.

Consider the flow rate; it directly impacts performance. High flow rates ensure efficient operation, preventing buildup in the system. Look for a unit that matches your compressor's capacity.

Another essential factor is the filtration level. A good filter dryer should trap moisture, dirt, and other contaminants. Check the micron rating; lower numbers indicate better filtration. It's also smart to evaluate the maintenance requirements. Some models require frequent checks and changes, while others can run longer before needing attention.

Durability matters too. The materials used in construction influence longevity. A robust design can withstand harsh environments. Also, think about operating temperatures; some dryers work better in specific ranges. Reflect on these details. You want a unit that fits your needs and is efficient over time.

When selecting an air compressor filter dryer for 2026, understanding the available options is crucial. Studies indicate that compressed air quality can significantly affect equipment performance. For instance, about 70% of industrial air failures are linked to moisture in the system. This makes choosing the right filter dryer essential for operational efficiency.

A recent report highlighted that desiccant dryers are becoming increasingly popular. These models excel at removing moisture even in low temperatures. They can reduce dew points by up to 40 degrees Fahrenheit, ensuring clean compressed air. However, they often require more maintenance than other types. Users need to consider the balance between maintenance demands and performance benefits.

Membrane dryers are another noteworthy option. They are compact and energy-efficient, suitable for small spaces. However, these dryers might not handle large moisture loads effectively. They work best in stable environments where air demands are predictable. Customers must weigh the advantages against their specific operational needs. Selecting the right type demands careful thought about application requirements and potential limitations.

Choosing the right air compressor filter dryer is crucial for efficient performance. Regular maintenance can significantly extend its lifespan. Keeping the filter clean is essential. A clogged filter can reduce airflow by up to 40%. This affects the compressor’s efficiency and energy consumption.

Inspecting the filter monthly is a good practice. Replace it if it looks worn out or damaged. In extreme environments, consider checking more frequently. According to industry reports, ignoring maintenance can lead to costly repairs, sometimes exceeding 30% of the compressor’s initial cost.

Additionally, condensation build-up can be problematic. Regularly draining the moisture from your air lines is recommended. If moisture accumulates, it can lead to rust and degradation of internal components. Regularly assessing the compressor’s operating temperature is beneficial. High temperatures can indicate operational stress. Monitoring these factors helps improve the durability of your filter dryer. Remember, maintenance is often overlooked but is vital for longevity.

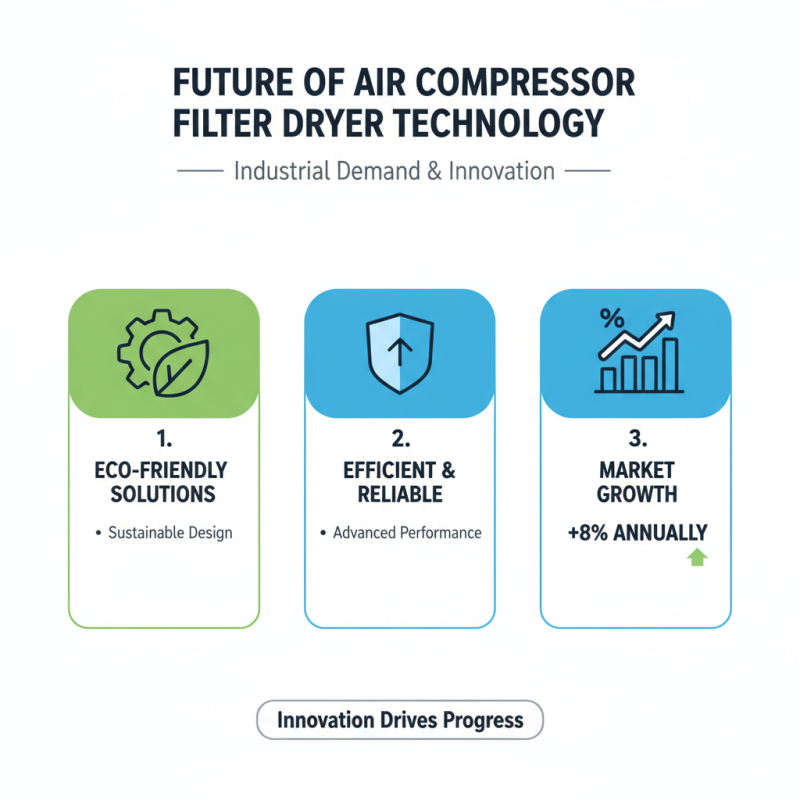

The future of air compressor filter dryer technology is exciting. Industrial applications increasingly demand efficient, reliable, and eco-friendly solutions. Reports indicate that the market for these devices is expected to grow by 8% annually. This trend emphasizes the need for advancements in design and performance.

One emerging trend is the integration of IoT technology. Smart filter dryers can monitor performance in real-time. They reduce downtime by predicting maintenance needs. This innovation allows for more proactive management of air quality. However, the implementation of connected systems raises concerns about cybersecurity. Companies must address these potential risks.

Tip: Regular maintenance can extend the life of your filter dryer. Even the most advanced models require check-ups. Neglecting routine care can lead to inefficiencies and increased costs.

Another trend is energy efficiency. Many new models use less energy while maintaining performance. The use of lower energy levels minimizes the environmental impact. However, some older models may not be compatible with newer technologies. Upgrading can be costly, but necessary for compliance and efficiency.

Tip: Consider energy audits for your equipment. They can reveal potential savings and highlight areas for improvement. Upgrading to more efficient models is an investment, not just a cost.