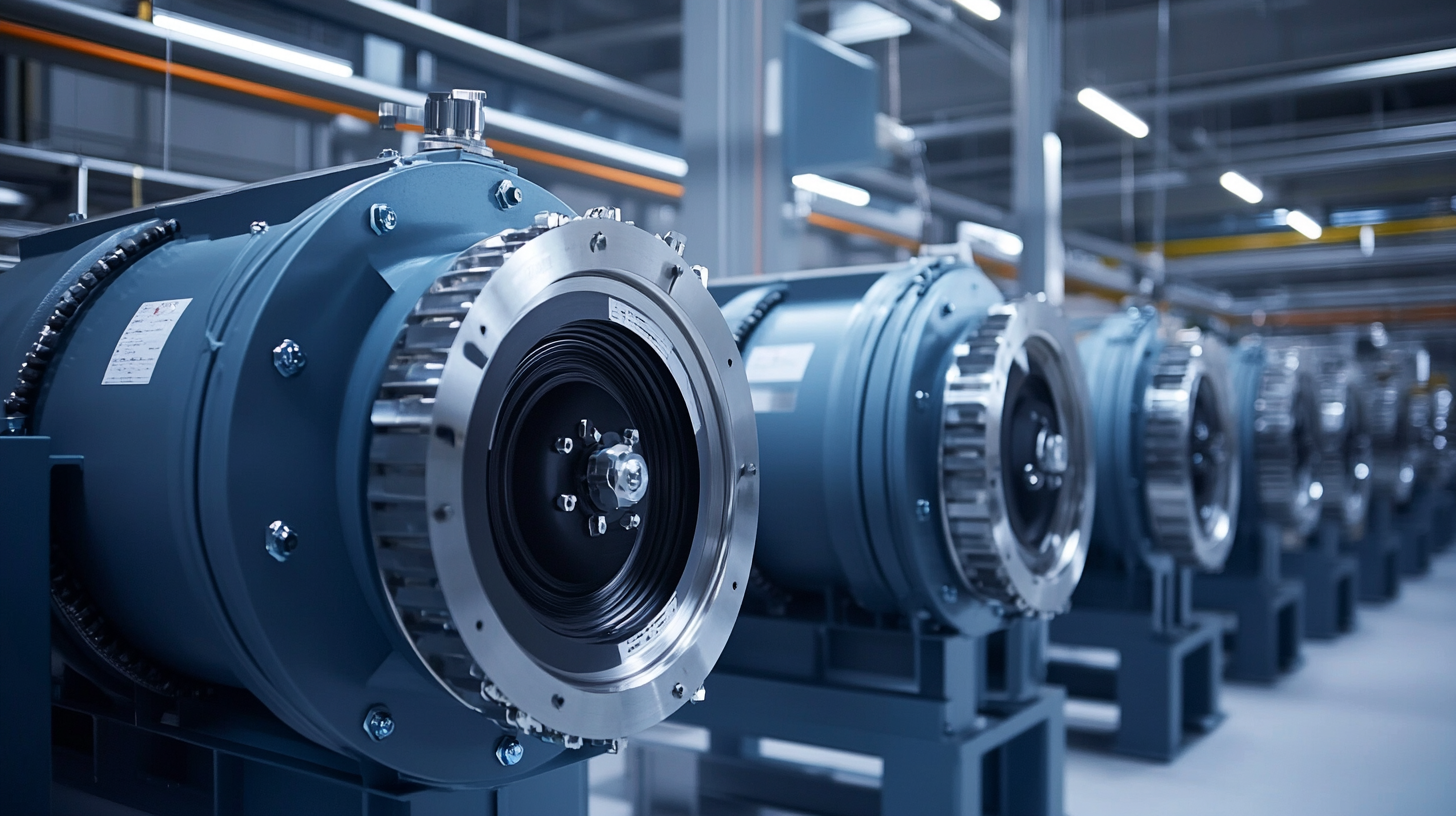

In the industrial sector, safety and reliability are paramount, especially when dealing with potentially hazardous environments. This is where the importance of an Explosion Proof Blower comes into play. These specialized blowers are designed to operate safely in settings with flammable gases or dust, ensuring that workers and equipment remain protected. China's trusted manufacturing industry has made significant advancements in the production of these high-quality blowers, combining innovative technologies with stringent quality control measures. In this blog, we will explore the uncompromising quality assurance practices employed by Chinese manufacturers, the key features that make Explosion Proof Blowers essential for various applications, and the reasons why businesses worldwide increasingly rely on these products to enhance safety and efficiency in their operations. Join us as we delve into the world of explosion-proof solutions and their critical role in safeguarding both people and property.

When it comes to manufacturing explosion proof blowers, adhering to stringent quality standards is vital. These standards ensure that the blowers can withstand hazardous environments and effectively mitigate the risks associated with explosive gases or dust. In industries such as oil and gas, pharmaceuticals, and chemicals, investing in blowers that meet high-quality benchmarks not only protects equipment but also safeguards workers' lives.

China has emerged as a trusted manufacturing hub for these specialized blowers, thanks to its commitment to quality control and adherence to international safety standards. Manufacturers implement rigorous testing and certification processes to guarantee that each unit can operate safely under extreme conditions. This focus on uncompromising quality fosters confidence among clients who require reliable equipment that can operate efficiently in potentially dangerous situations. By prioritizing quality assurance, these manufacturers not only fulfill regulatory obligations but also contribute to a culture of safety and reliability in industries that cannot afford any compromise.

This chart illustrates the importance of various quality standards in the manufacturing of explosion proof blowers. The data represents the percentage of manufacturers adhering to specific quality certifications.

When selecting high-quality explosion-proof blowers, there are several key features to prioritize. First and foremost, the construction materials play a vital role in ensuring durability and safety. Look for blowers made from robust materials that can withstand harsh environments and resist corrosion, such as aluminum and stainless steel. This not only extends the life of the blower but also enhances its reliability in potentially hazardous situations.

Another important feature to consider is the blower’s certification. Trusted manufacturers from China should comply with international safety standards such as ATEX and IECEx. These certifications ensure that the blowers are designed and tested to operate safely in explosive atmospheres, providing peace of mind to users in industries like oil and gas, chemicals, and mining. Additionally, efficient airflow performance is crucial, as it ensures optimal operation without compromising safety. Premium blowers balance powerful airflow with minimal noise levels, contributing to a safer and more comfortable working environment.

China has emerged as a dominant player in the global market for explosion-proof blowers, driven by its robust manufacturing capabilities and stringent quality control measures. According to a report by Research and Markets, the global explosion-proof equipment market is projected to reach approximately $13.5 billion by 2027, with China accounting for a significant share due to its supply of high-quality, competitively priced products. This growth is fueled by increasing industrial activity and stricter safety regulations worldwide, compelling manufacturers to invest in reliable explosion-proof technology.

Moreover, China's advanced manufacturing infrastructure enables the production of blowers that meet international safety standards. A survey by MarketsandMarkets indicates that the Asia-Pacific region is expected to register the highest growth rate in the explosion-proof blower market, highlighting the region's pivotal role in exporting these crucial safety devices. With innovative designs and adherence to ISO standards, Chinese manufacturers are not only boosting their local economies but also reinforcing their position in global supply chains, proving that uncompromising quality can originate from anywhere in the world.

In the ever-evolving field of industrial safety, explosion-proof blowers have emerged as crucial equipment to mitigate the risks associated with hazardous environments. Recent advancements in innovative technologies are significantly enhancing the performance and reliability of these blowers. According to a report by MarketsandMarkets, the global explosion-proof equipment market is expected to reach $10.7 billion by 2025, indicating a strong demand for technologically advanced solutions that prioritize safety and efficiency in processing plants and other sensitive applications.

Leading manufacturers in China have been at the forefront of these technological innovations, employing cutting-edge materials and design techniques to elevate the standards of explosion-proof blowers. For instance, the integration of smart sensors and IoT capabilities enables real-time monitoring of blower performance, allowing operators to respond promptly to any irregularities. Additionally, advancements in motor technology have resulted in blowers that not only offer superior energy efficiency but also achieve better airflow performance while maintaining compliance with stringent explosion protection standards set forth by organizations like ATEX and IECEx. This combination of enhanced performance and rigorous safety standards positions Chinese explosion-proof blowers as trusted solutions for industries requiring uncompromising quality and reliability.

| Feature | Description | Benefits |

|---|---|---|

| Explosion Proof Certification | Complies with international safety standards for hazardous environments. | Ensures safety and reliability in explosive atmospheres. |

| Innovative Blower Design | Aerodynamically optimized for efficient airflow and pressure. | Reduces energy consumption and enhances performance. |

| High-Quality Materials | Utilizes robust materials such as stainless steel and high-grade plastics. | Increases durability and lifespan of the blowers. |

| Advanced Motor Technology | Incorporates energy-efficient motors with low heat generation. | Enhances performance while reducing operational costs. |

| Customization Options | Offers tailored solutions to meet specific industry needs. | Provides flexibility and efficiency for different applications. |

In the realm of explosion-proof blowers, quality and safety are paramount, particularly in explosive environments. With the rise of electric vehicles and their dependence on powerful batteries, rigorous quality standards have never been more critical. As of 2024, China boasts a staggering 31.4 million electric vehicles, leading globally in battery installation. However, this surge has also introduced potential safety hazards, exemplified by incidents involving electric bicycles where substandard batteries led to fires and explosions. Data from industry reports highlight the urgent need for compliance with safety regulations and quality assurance in manufacturing to mitigate such risks.

To address these challenges, manufacturers must adopt rigorous testing and quality control measures in their production processes. The lessons learned from the recent battery fires underscore that even established brands can face dire consequences when quality is compromised. Reports indicate that up to 60% of safety incidents in electric vehicles are battery-related, but implementing high standards in the production of explosion-proof blowers can significantly reduce these risks. By prioritizing uncompromising quality, manufacturers can ensure their products not only meet regulatory requirements but also contribute to a safer working environment in industries exposed to explosive hazards.