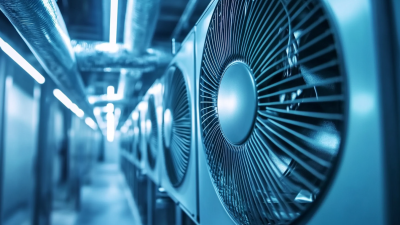

In the ever-evolving world of HVAC systems, the efficiency of condenser fan motors plays a pivotal role in optimizing performance and energy consumption. Experts in the field, such as Dr. Emily Carter, a renowned HVAC efficiency consultant, emphasize the importance of these components. Dr. Carter states, "Investing in high-performance condenser fan motors not only enhances cooling efficiency but also significantly reduces operational costs."

As the demand for energy-efficient solutions continues to rise, selecting the right condenser fan motor becomes crucial for both residential and commercial applications. With advancements in technology, high-performance motors have emerged as game-changers, delivering superior airflow and lower energy usage. This article explores the top five benefits of upgrading to high-performance condenser fan motors, illustrating how these innovations contribute to ultimate cooling solutions.

By focusing on maximizing HVAC efficiency through the integration of advanced condenser fan motor technology, businesses and homeowners alike can reap significant benefits. From increased cooling capacity to reduced environmental impact, the right choice in condenser fan motors can lead to enhanced comfort and cost savings, further establishing their essential role in modern HVAC systems.

The integration of high-performance condenser fan motors in HVAC systems is proving to be a game-changer in energy efficiency ratings. According to the U.S. Department of Energy, traditional motors can waste significant energy, with efficiency rates often falling below 60%. In contrast, high-performance motors can achieve efficiencies exceeding 90%, drastically reducing operational costs and energy consumption. By implementing these advanced motors, HVAC systems not only enhance cooling performance but also lower greenhouse gas emissions, contributing to overall sustainability goals.

Furthermore, research conducted by the Consortium for Energy Efficiency (CEE) indicates that upgrading to high-performance motors can lead to energy savings of up to 40% in commercial HVAC applications. This notable decrease in energy usage translates into reduced running costs and a quicker return on investment for businesses. With the push towards more energy-efficient solutions, stakeholders in the HVAC industry are increasingly recognizing the vital role that these advanced motors play in meeting stringent energy efficiency standards and enhancing system reliability.

In recent years, the role of condenser fan motors in cooling systems has gained significant attention, especially from an environmental perspective. These motors are crucial in optimizing the performance of HVAC systems, and their efficiency directly correlates with greenhouse gas (GHG) emissions. According to the U.S. Department of Energy, upgrading to high-performance condenser fan motors can reduce energy consumption by up to 30%, which translates to a considerable reduction in carbon emissions.

The Environmental Protection Agency (EPA) estimates that HVAC systems account for approximately 10% of total energy use in buildings, contributing significantly to GHG emissions. By implementing energy-efficient condenser fan motors, facilities can not only enhance cooling efficiency but also play an active role in climate change mitigation. Research from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) has demonstrated that optimized condenser fan motors can lead to lower operational costs and improved system longevity, showcasing their dual benefit of environmental stewardship and economic efficiency.

| Parameter | Conventional Motors | High Performance Motors | GHG Emissions Reduction (%) |

|---|---|---|---|

| Power Consumption (kW) | 2.5 | 1.8 | 28% |

| Cooling Capacity (BTU/h) | 40000 | 45000 | - |

| Annual Operating Hours | 2000 | 2000 | - |

| Annual Energy Cost ($) | 600 | 430 | 28% |

| Total GHG Emissions (kg CO2/year) | 1200 | 864 | 28% |

In recent years, the HVAC industry has seen a significant shift towards high efficiency condenser fan motors, which offer considerable advantages over traditional motors. One of the key factors driving this change is the potential for substantial cost savings. High efficiency motors typically consume less energy, leading to lower utility bills in both residential and commercial applications. When considering the long-term financial impact, businesses and homeowners alike can benefit from reduced operating expenses while enjoying optimal cooling performance.

Moreover, the initial investment in high performance condenser fan motors can often be offset by the savings accrued through their enhanced efficiency. These advanced motors are designed to operate at higher levels of output with lower energy consumption, ultimately reducing wear and tear on the cooling system. This longevity means fewer replacements and maintenance costs over time, further enhancing their economic appeal. As the HVAC sector continues to evolve, the comparative analysis between traditional and high efficiency motors becomes increasingly relevant, emphasizing the importance of making informed choices for sustainable cooling solutions.

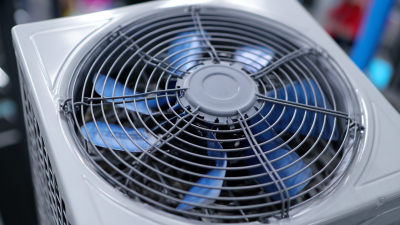

In today's quest for enhanced HVAC efficiency, technological innovations in condenser fan motors are revolutionizing cooling solutions. Recent advancements have led to motors capable of boosting cooling performance by as much as 30%. These high-performance motors not only improve airflow but also reduce energy consumption, making them a smart investment for both residential and commercial applications. Enhanced designs incorporate variable speed technology, allowing the fans to adjust their operation according to the cooling needs, leading to further efficiency gains.

When considering an upgrade to high-performance condenser fan motors, here are a few tips to keep in mind. First, ensure that the motor's specifications match your system requirements for optimal compatibility and performance. Regular maintenance is also crucial; routine checks can prolong the lifespan of your motors and ensure they run at peak efficiency. Lastly, consult with HVAC professionals to determine the best options for your specific needs, as they can provide insights tailored to your environment and application.

By embracing these innovations, facilities can not only enjoy a more comfortable climate but also significantly lower energy costs, contributing to a more sustainable future.

When selecting high-performance condenser fan motors for HVAC systems, it is crucial to consider several factors that can enhance efficiency and reliability. First, evaluate the motor's efficiency rating, ideally opting for units with high Energy Efficiency Ratio (EER) metrics. This will not only help reduce energy consumption but also lead to lower operating costs over time. Additionally, selecting a motor with appropriate horsepower for the specific application ensures optimal cooling performance while preventing undue strain on the system.

Maintenance practices also play a pivotal role in maximizing the longevity and functionality of condenser fan motors. Regular inspections should be conducted to check for any signs of wear or potential issues such as loose connections or debris accumulation. Implementing a routine lubrication schedule for moving parts can significantly enhance performance and reduce the risk of unexpected failures. Furthermore, investing in quality components and adhering to manufacturer guidelines during installation and operation can help sustain the efficiency of the HVAC system, ensuring it remains reliable throughout its lifespan.