As industries continue to evolve in the face of rapid technological advancements, the furnace motor sector stands out as a critical area of innovation impacting global procurement strategies. According to a recent report by Research and Markets, the global furnace motor market is projected to grow at a CAGR of 6.2% from 2021 to 2026, driven by increasing energy efficiency demands and the push towards automation in manufacturing. Companies are increasingly recognizing that integrating advanced furnace motor technologies not only enhances operational efficiency but also aligns with sustainability goals.

Furthermore, the rise of smart manufacturing and IoT integration is transforming how procurement departments evaluate their supply chains, making it essential to stay updated on the latest furnace motor innovations. This blog will delve into five groundbreaking innovations in furnace motor technology and their implications for procurement strategies worldwide, illustrating how businesses can harness these advancements to gain a competitive edge in the market.

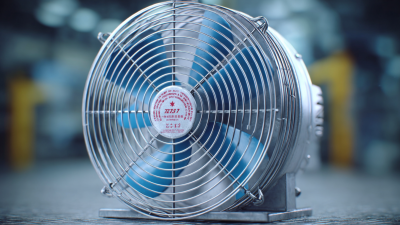

The rise of smart furnace motors presents a transformative opportunity for industries reliant on heating solutions, enhancing both efficiency and performance. According to a recent report by the International Energy Agency (IEA), smart technologies in manufacturing can reduce energy consumption by up to 30%. This not only leads to significant cost savings but also contributes towards a more sustainable approach in industrial operations. With advancements in sensor technology and data analytics, smart furnace motors can monitor operational conditions in real-time, optimizing performance and minimizing energy waste.

Furthermore, a study by Research and Markets indicates that the global smart motor market is anticipated to grow at a compound annual growth rate (CAGR) of 7.5% from 2022 to 2028. Factors driving this growth include the increasing adoption of IoT applications across various sectors and the escalating demand for energy-efficient solutions. These innovations enable real-time diagnostics and predictive maintenance capabilities, significantly reducing downtime and enhancing overall operational efficiency. As businesses adapt their procurement strategies to these advancements, the integration of smart furnace motors is set to redefine industry standards and practices.

In today's manufacturing landscape, sustainability is reshaping furnace motor designs, heralding a new era for global procurement strategies. According to the International Energy Agency (IEA), motors account for approximately 45% of total industrial electricity consumption. Consequently, transitioning to energy-efficient furnace motors is not just an environmental imperative but also a strategic business decision that can yield significant cost savings. Innovations like using advanced materials and smart technologies are making these motors more efficient, reducing operational costs by as much as 30% over their lifetime.

Tip: When evaluating furnace motors, consider those with higher efficiency ratings, like IE4 or IE5, which offer improved performance while adhering to sustainability standards. Additionally, engage with suppliers that prioritize eco-friendly practices in their sourcing and manufacturing processes.

Moreover, the shift towards sustainability is further driven by regulatory pressures and consumer demand for greener products. Reports from market analysts suggest that procurement teams that incorporate sustainability criteria into their supplier assessments can enhance their competitive edge in the global marketplace. This transition not only mitigates risks associated with regulatory compliance but also appeals to conscious consumers who are increasingly prioritizing sustainable practices.

Tip: Collaborate with suppliers committed to sustainability initiatives. This partnership can provide innovative solutions that align with your procurement strategy while also reducing your carbon footprint.

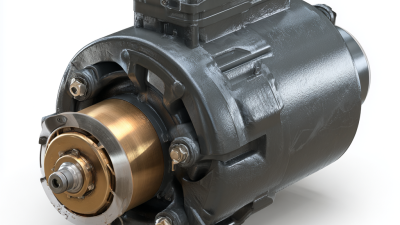

The advent of IoT technologies is revolutionizing furnace motor innovations, fundamentally altering global procurement strategies in the process. As manufacturers integrate smart sensors and real-time monitoring systems into furnace motors, the efficiency and performance metrics of these systems have dramatically improved. Reports indicate that the global electric motor winding machine market will be valued at approximately $1.4 billion by 2024, expected to surge to around $2.68 billion by 2033, reflecting a robust growth rate of 7.5%. This significant increase signals a pressing need for procurement teams to adapt and embrace the trend towards smarter, interconnected systems.

Moreover, IoT integration allows for predictive maintenance, reducing downtime, and optimizing supply chain efficiency. Stakeholders are investing in technologies that empower real-time data analysis to anticipate failures before they occur. Such innovations not only benefit operational performance but also enhance procurement processes by shifting focus from reactive to proactive strategies. As the market evolves, those who leverage IoT advancements in furnace motor innovation stand to gain a competitive advantage, solidifying their position in an increasingly data-driven industry.

The furnace motor industry is experiencing a significant shift, with innovative technologies driving cost-effective procurement strategies that benefit manufacturers and suppliers alike. According to a report by Research and Markets, the global furnace motor market is projected to grow at a CAGR of over 5% through 2025, highlighting the increasing demand for efficient and advanced motor systems. Procurement strategies must now adapt to incorporate these innovations, which not only enhance performance but also mitigate operational costs.

One of the most notable advancements is the integration of smart motor technology. These motors utilize IoT connectivity, allowing for real-time monitoring and predictive maintenance, ultimately reducing downtime and maintenance costs. A study from Allied Market Research indicates that smart motor systems can reduce energy consumption by up to 30%, translating directly into lower operational expenses. Consequently, procurement strategies that leverage these technologies can yield substantial savings over traditional systems.

Furthermore, with the rise of sustainable practices, many manufacturers are seeking motors that meet stringent energy efficiency standards. According to the U.S. Department of Energy, energy-efficient motors can decrease greenhouse gas emissions significantly. By focusing on these advanced, eco-friendly options, procurement teams not only comply with regulations but also enhance their organizations' reputation, fostering long-term partnerships with suppliers committed to sustainability.

In the rapidly evolving landscape of furnace motor technologies, procurement strategies are facing unprecedented challenges. Companies are now tasked with navigating a complex supply chain influenced by geopolitical factors, environmental regulations, and fluctuating market demands. As furnace motors become increasingly sophisticated, integrating features such as energy efficiency and smart technology, procurement teams must rethink their sourcing strategies to ensure they align with these innovations.

The integration of new technologies in furnace motors necessitates collaboration between suppliers and manufacturers, fostering a more transparent and responsive supply chain. By leveraging data analytics and real-time monitoring, businesses can better anticipate demand fluctuations and manage inventory more effectively. Additionally, diversifying the supplier base allows companies to mitigate risks associated with supply chain disruptions, ensuring a steady flow of innovative products.

Embracing agility in procurement practices not only enhances operational resilience but also supports ongoing innovation in furnace motor design and functionality.