A Filter Dryer plays a crucial role in various industrial processes. It combines filtration and drying in one unit. This dual function enhances efficiency and reduces processing time. Manufacturers across sectors rely on it for clean and dry products.

The operation of a Filter Dryer is fascinating. Initially, it removes solid particles from liquids. Then, the integrated drying mechanism evaporates excess moisture. This results in a high-quality end product, suitable for further use. However, challenges exist. The design must balance efficiency and simplicity.

In many cases, users may overlook maintenance needs. Neglect can lead to reduced performance. Understanding the principles behind a Filter Dryer is essential. It can help optimize operations and improve product quality.

A filter dryer is an essential piece of equipment in many industries. It combines filtration and drying processes to efficiently remove impurities from materials. This device is widely used in food processing, pharmaceuticals, and chemicals. According to industry reports, about 30% of production losses occur due to impurities. Filter dryers help tackle this issue.

How does it work? The process starts with the introduction of a slurry or liquid into the filter dryer. As the material flows, a filter medium captures solid particles. Next, heat is applied to evaporate solvents or moisture. This dual action—filtration and drying—can significantly enhance product quality. Statistics show that using a filter dryer can improve yields by up to 25%.

However, there are challenges. For instance, filter clogging can occur, affecting operational efficiency. Additionally, improper temperature control may lead to material degradation. Continuous monitoring and adjustments are necessary to maintain optimal conditions. Many facilities strive to minimize these risks, yet some still face issues with their systems. The importance of proper training and maintenance cannot be overstated.

Filter dryers are essential in various industries for drying and filtering processes simultaneously. They combine filtration and drying in one unit. This design simplifies operations and enhances efficiency. It removes liquid from solids, often used in pharmaceuticals and food processing.

The working principle of filter dryers is straightforward yet effective. A slurry enters the filter dryer, where it is held within a chamber. The liquid phase is drawn away under vacuum. During this process, solid particles are left behind. Hot air or steam is often used to facilitate drying. This method ensures a consistent final product with minimal moisture content.

However, challenges do arise. Not all materials dry uniformly. Sometimes, uneven heating occurs, leading to clumping. Operators must monitor conditions carefully. Adjustments are needed to optimize performance. It's a balance between time, temperature, and pressure. Continuous improvement is key to mastering this technology.

A filter dryer is an essential piece of equipment in various industries. Its main role is to remove moisture and solid particles from liquids. The operation relies on a few key components that work in harmony. Understanding these components can enhance efficiency and performance.

The filter element is crucial. It captures solid contaminants during the filtering process. When the element becomes clogged, the flow reduces. This hinders performance. Regular maintenance is then necessary. The drying chamber is equally important. It ensures effective moisture removal. However, if the temperature is too high, it can lead to material degradation. Monitoring this is essential, but sometimes overlooked.

Another key component is the vacuum system. It creates a low-pressure environment within the dryer. This step aids in moisture removal. Yet, if the vacuum isn't sufficient, it may not function properly. Finally, consider the control panel. Operators frequently adjust settings. Errors in these adjustments can lead to inefficiency. Being mindful of these details can improve overall operations.

Filter dryers are increasingly popular in various industries. They excel in separating solids from liquids, making them essential for many processes. One of the main advantages of using filter dryers is their ability to reduce processing time. They can combine filtration and drying in one unit. This saves both space and energy.

Another advantage is the high quality of the final product. Filter dryers ensure that the solid material is pure and free from contaminants. This is crucial for pharmaceuticals and food production. Additionally, they minimize handling. Fewer transfers reduce the risk of contamination. However, sometimes the initial cost can be high.

Operators must also maintain these systems properly. Neglecting maintenance can lead to inefficiencies or breakdowns. It’s essential to monitor performance regularly. Attention to detail is key. Despite these challenges, the benefits often outweigh the downsides. Enhanced efficiency and purity make filter dryers a powerful tool in manufacturing.

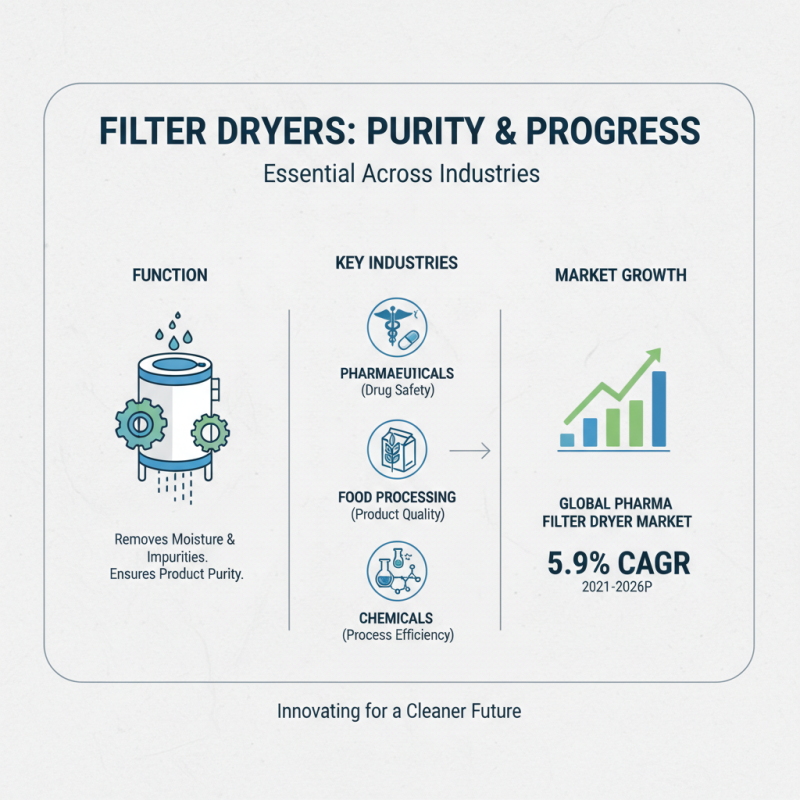

Filter dryers play a crucial role in various industries, handling the removal of moisture and impurities from products. These systems are particularly vital in pharmaceuticals, food processing, and chemicals. In pharmaceuticals, filter dryers ensure the highest purity, which is essential for drug safety. The global pharmaceutical filter dryer market is expected to grow significantly, projected at a CAGR of 5.9% from 2021 to 2026.

In food processing, they are used to concentrate flavors and preserve quality. Filter dryers help in producing dehydrated fruits and instant soups. Some reports indicate that the food and beverage industry accounts for about 35% of the global filter dryer market. This highlights the importance of these systems in maintaining product integrity.

Tips: Always assess the specific needs of your application. Not all filter dryers are the same. Consider the nature of your product and processing requirements when choosing a system. It's wise to consult experts to avoid costly mistakes.

Maintenance of filter dryers is also essential. Overlooking this can lead to inefficiencies. Regular cleaning can improve energy use and extend the lifecycle of equipment. However, some facilities often neglect scheduled maintenance, which leads to problems down the line. Balancing efficiency and upkeep is a continual challenge in many industries.