In the realm of modern engineering, "Fan Motors" play a pivotal role across various industries, driving efficiency and innovation in applications ranging from HVAC systems to industrial machinery. According to Dr. Emily Carter, an expert in thermal dynamics and mechanical engineering, “The integration of fan motors in systems not only enhances performance but also significantly contributes to energy conservation.” This profound insight underscores the importance of understanding how fan motors operate and their relevance in diverse applications.

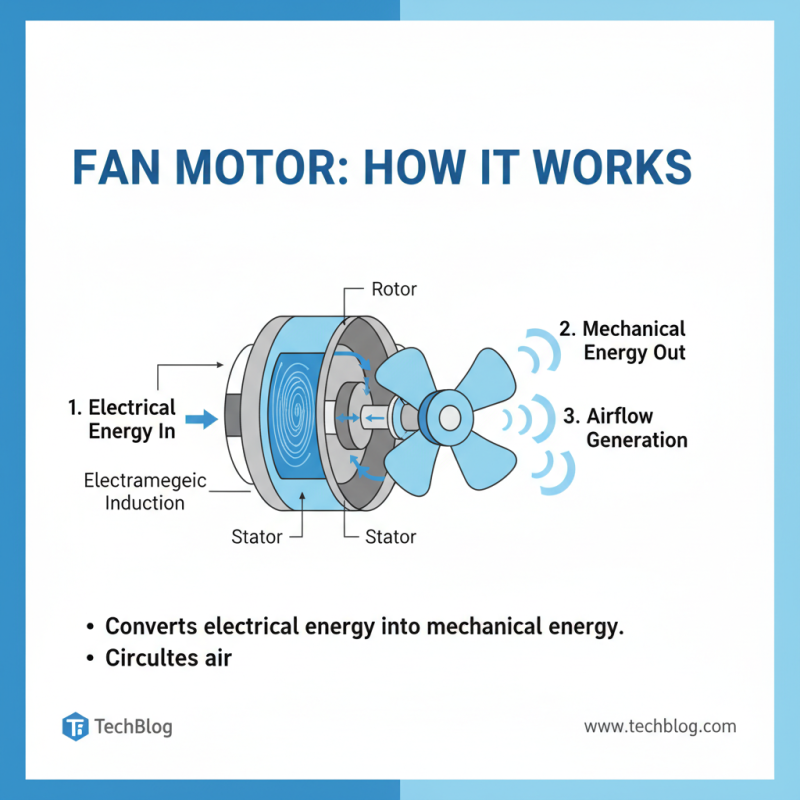

Fan motors, comprising an electric motor connected to a fan blade, function by converting electrical energy into mechanical energy, thereby producing airflow. Their functionality varies significantly depending on the application— from providing cooling in residential settings to ensuring proper ventilation in commercial buildings and facilitating processes in manufacturing plants. The adaptability of fan motors makes them essential in optimizing system performance and enhancing user comfort. As we delve deeper into the mechanics of these crucial components, we uncover the nuances that differentiate their operation across various environments and applications, highlighting their indispensable role in today's technological landscape.

A fan motor is an essential component used in various mechanical and electrical systems, primarily designed to convert electrical energy into mechanical energy to create airflow. These motors operate by using electromagnetic induction, where a flowing electric current generates a magnetic field. This magnetic field interacts with the rotor (the rotating part of the motor), leading to rotation and driving the attached fan blades, which circulate air.

In different applications, fan motors cater to specific requirements. For instance, in HVAC systems, they ensure proper ventilation and temperature control, while in industrial settings, they help cool down machinery and maintain operational efficiency. The versatility of fan motors allows them to be effectively utilized in home appliances, such as exhaust fans and air conditioners, as well.

**Tips:** When choosing a fan motor, consider factors like size, voltage, and intended use to ensure optimal performance. Regular maintenance, such as cleaning the blades and checking for electrical issues, can extend the lifespan of the fan motor. Additionally, using energy-efficient motors can not only reduce electricity costs but also contribute to environmental sustainability.

A fan motor is a crucial component in various applications, from HVAC systems to industrial machinery. Understanding its components can help users appreciate its functionality and maintain efficiency. Typically, a fan motor consists of several key parts, including the rotor, stator, bearings, and housing. The rotor spins within the stator, creating airflow. Bearings support the rotor and ensure smooth operation, while the housing protects internal components and guides airflow direction.

According to industry reports, such as those published by the International Air-Conditioning, Heating, and Refrigerating Exposition (AHR Expo), efficient fan motors can significantly reduce energy consumption. For instance, switching to high-efficiency motors can lead to energy savings of 20% or more in commercial settings, which underlines the importance of quality components.

**Tips:** When selecting a fan motor, consider the application requirements and environmental factors. A motor designed for high humidity or corrosive environments should have weather-resistant features. Regular maintenance, including lubrication of bearings and ensuring clean fan blades, can enhance the motor’s lifespan and performance, optimizing energy efficiency in day-to-day operations.

| Component | Function | Common Applications | Power Source |

|---|---|---|---|

| Stator | Provides stationary magnetic field | HVAC systems, industrial fans | AC or DC power |

| Rotor | Rotates in response to magnetic field | Cooling systems, exhaust fans | AC or DC power |

| Fan Blades | Moves air when the rotor spins | Computers, air conditioning units | AC or DC power |

| Housing | Protects components and directs airflow | Ceiling fans, portable fans | N/A |

| Motor Windings | Creates magnetic field when energized | Ventilation systems, exhaust hoods | AC or DC power |

Fan motors are pivotal components in various applications, providing essential airflow and temperature control in a multitude of settings, from residential homes to industrial facilities. In HVAC systems, fan motors help circulate air, ensuring efficient heating, cooling, and ventilation. According to the U.S. Department of Energy, approximately 20% of energy usage in residential buildings can be attributed to heating and cooling systems, highlighting the importance of optimized fan motor performance in energy efficiency and cost reduction.

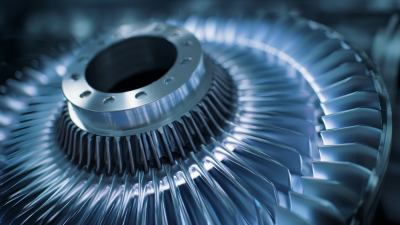

In industrial environments, fan motors function in a range of operations, including material handling, dust collection, and process cooling. Direct-drive fan motors are commonly utilized due to their reliability and minimal maintenance requirements. A report from the International Energy Agency notes that industrial fans account for about 6% of global electricity consumption, implying that advancements in fan motor technology could significantly reduce energy expenditures. Variable speed motors have emerged as a solution to this, enabling precise airflow control and energy savings.

Tips: For those looking to enhance fan motor efficiency, consider implementing variable frequency drives (VFDs) that adjust motor speed according to demand. This not only minimizes energy usage but also prolongs the service life of the equipment. Additionally, regular maintenance such as cleaning and lubrication can prevent performance degradation and increase the longevity of fan motors across different applications.

Fan motors play a pivotal role in various household appliances, providing essential airflow and influencing energy efficiency. They are commonly found in devices such as ceiling fans, exhaust fans, and refrigerators, where they help in maintaining a comfortable climate and ensuring proper ventilation. According to industry reports, the global market for fan motors in household applications is projected to reach $3.6 billion by 2025, driven by an increasing demand for energy-efficient appliances and smart home solutions.

In ceiling fans, for instance, fan motors operate to circulate air effectively, allowing for temperature regulation without the need for air conditioning. This can lead to energy savings of up to 40%, which is significant given that home cooling accounts for about 12% of total energy use in the U.S. In refrigerators, fan motors are essential for ensuring even cooling, which helps in prolonging the shelf life of food items. An efficient fan motor in a refrigerator can contribute to a reduction in energy consumption by approximately 15%.

**Tips:** Consider investing in appliances with high-efficiency fan motors, as they not only reduce energy costs but also have a lower environmental impact. Regular maintenance, such as cleaning fan blades and ensuring unobstructed airflow, can enhance the performance and longevity of these motors. Additionally, utilizing timers or smart controls can optimize fan use based on your household's needs, maximizing both comfort and efficiency.

Fan motors play a crucial role in numerous industrial applications, ensuring efficient operation across various sectors. According to a report by Research and Markets, the global industrial fan market is projected to reach USD 13.6 billion by 2026, driven by increasing demand for efficient ventilation and cooling systems. These motors are essential in environments where airflow management is critical, such as in HVAC systems, manufacturing plants, and power generation facilities. Their ability to regulate temperature and air quality not only improves operational efficiency but also enhances worker safety and comfort.

Moreover, fan motors are integral in the food processing and storage industries, where temperature control is vital to maintain product integrity. For example, the U.S. Department of Agriculture emphasizes the importance of proper ventilation to inhibit spoilage and ensure food safety. With advancing technologies, such as variable frequency drives, fan motors are becoming more energy-efficient, allowing industries to reduce their operational costs significantly. This increased efficiency is not just a financial benefit but also contributes positively to sustainability goals, aligning with industry standards for environmental responsibility.