In the realm of HVAC systems, the condenser fan motor plays a pivotal role in ensuring efficient cooling and maintaining optimal performance. According to industry expert John Smith, a recognized authority in HVAC technology, "A well-functioning condenser fan motor is crucial for the overall efficiency of cooling systems." Understanding the function and mechanics of a condenser fan motor is essential for both technicians and homeowners alike, as it directly impacts the performance of air conditioning units.

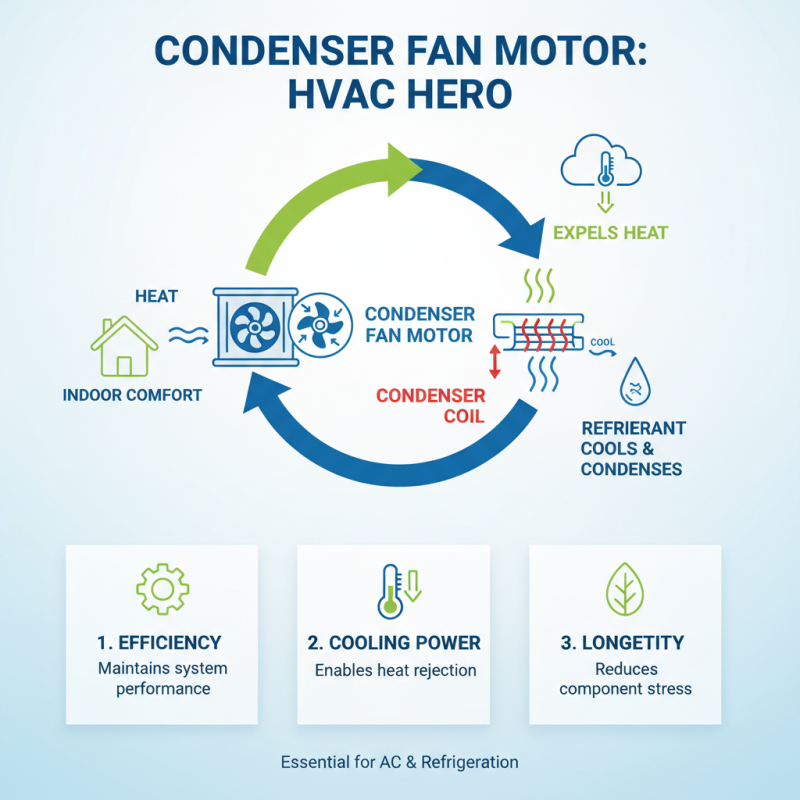

The condenser fan motor is responsible for driving the fan that dissipates heat from the refrigerant in the condenser coil. By producing cooled air that aids in this process, it significantly enhances the system's capacity to cool indoor spaces. Additionally, the proper maintenance and timely replacement of the condenser fan motor can lead to improved energy efficiency, ultimately reducing operational costs. This introduction sets the stage for a detailed exploration of how the condenser fan motor operates, its components, and best practices for upkeep, ensuring HVAC systems run smoothly and effectively.

A condenser fan motor is a crucial component in the operation of air conditioning systems and refrigeration units. It is primarily responsible for expelling heat from the condenser coil, allowing the refrigerant to cool down and condense into a liquid state. This process is essential for maintaining the efficiency and effectiveness of HVAC systems, ensuring that indoor environments remain comfortable.

Typically located outside the building, the condenser fan motor powers the fan that draws air over the condenser coils. As the fan circulates air, it helps dissipate the heat absorbed from the refrigerant, which is essential for the condensation process to occur. Without a properly functioning condenser fan motor, the system could overheat, leading to decreased performance and potential damage. These motors are designed to withstand harsh outdoor elements, and their reliable operation is vital in both residential and commercial refrigeration and air conditioning systems.

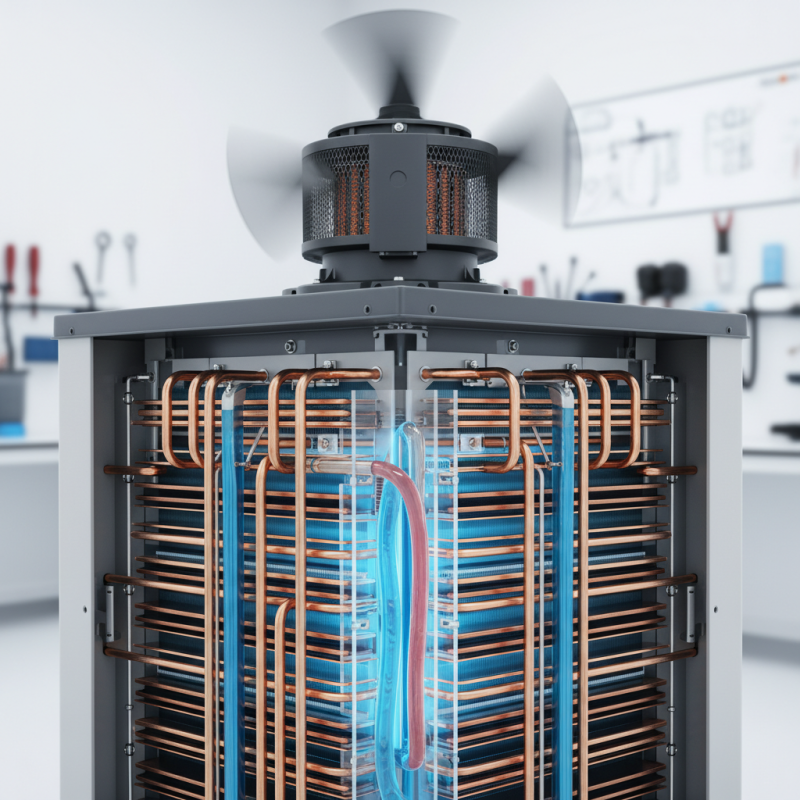

A condenser fan motor is a critical component in air conditioning systems, primarily responsible for cooling the condenser coil. This motor drives the fan, which circulates air over the condenser coil to dissipate heat efficiently. Understanding the key components of a condenser fan motor can help in troubleshooting and maintenance.

Key components of a condenser fan motor include the rotor, stator, bearings, and housing. The rotor is the rotating part of the motor, which moves when electrical energy is applied. The stator surrounds the rotor and generates a magnetic field that aids in its rotation. Bearings reduce friction between moving parts, ensuring smooth operation and extending the motor's lifespan. The housing encases these components, providing protection from external elements.

Tips: Regular maintenance of the condenser fan motor can significantly improve its efficiency and longevity. Ensure that the fan blades are clean and free of debris, as dust accumulation can hinder performance. Additionally, check the electrical connections for any signs of wear or corrosion to prevent potential failures. Keeping the motor lubricated as needed also plays a crucial role in reducing friction and enhancing performance.

A condenser fan motor plays a crucial role in the operation of air conditioning systems and refrigeration units. It is responsible for driving the fan that blows air over the condenser coils, facilitating heat exchange. The operation of a condenser fan motor is primarily based on electromagnetic induction, where electrical energy is converted into mechanical energy, creating rotational motion. This process is vital for dissipating heat from refrigerant by efficiently transferring thermal energy away from the condenser coils, allowing the cooling system to maintain optimal performance.

According to the U.S. Department of Energy, an efficient condenser fan motor can significantly improve energy consumption, with estimates indicating that high-efficiency motors can reduce energy use by up to 25% compared to standard models. This reduction not only saves costs for users but also contributes to a smaller carbon footprint. Understanding the importance of a well-functioning condenser fan motor can lead to prolonged equipment life and improved system reliability.

Tips: Regular maintenance of your condenser fan motor is essential for optimal performance. Ensure that the fan blades are free of debris and the motor is well-lubricated to prevent overheating. Additionally, consider upgrading to an energy-efficient model when replacing old motors, as this can lead to substantial energy savings over time.

A condenser fan motor plays a crucial role in the effective operation of air conditioning systems by helping to expel heat from the condenser unit. However, like any mechanical component, it can encounter various issues over time. Recognizing common problems can aid in troubleshooting and ensuring the unit operates efficiently.

One frequent issue with condenser fan motors is overheating, often caused by electrical problems or inadequate airflow. If the motor becomes excessively hot, it may shut down to prevent damage, resulting in reduced cooling efficiency. Inspecting the electrical connections and ensuring there are no obstructions in the airflow can help address this issue. Additionally, worn bearings or a failing fan blade can lead to unusual noises or vibrations, signaling the need for maintenance or replacement.

Another common problem is capacitor failure, which is essential for starting the motor. If the motor fails to start or runs erratically, it may be a sign that the capacitor is defective. Testing the capacitor with a multimeter can provide insight into whether it needs to be replaced. Regular maintenance, such as cleaning the fan blades and checking for debris in the unit, can help prevent these issues and prolong the lifespan of the condenser fan motor.

Proper maintenance of condenser fan motors is crucial for ensuring optimal performance and longevity. According to a report by the U.S. Department of Energy, regular maintenance can improve system efficiency by up to 30%. One of the primary tips for maintaining condenser fan motors is to ensure that the fan and surrounding area are free from debris. Dust, dirt, and other obstructions can impede airflow, leading to overheating and potential damage to the motor.

Additionally, lubricating the fan motor bearings regularly is essential for reducing friction and wear. Research from the Air-Conditioning, Heating, and Refrigeration Institute suggests that more than 60% of motor failures can be traced back to inadequate lubrication. Monitoring the electrical connections and ensuring they are secure and free from corrosion can also prevent unexpected failures. By adhering to these maintenance tips, users can significantly extend the life of their condenser fan motors while ensuring efficient operation.

| Dimension | Details |

|---|---|

| Motor Type | Permanent Split Capacitor (PSC) |

| Voltage Rating | 208-230V |

| Power Consumption | 1/4 to 1/2 HP |

| RPM (Revolutions Per Minute) | 1075 or 825 |

| Fan Size | 16 to 24 inches |

| Common Issues | Overheating, Noisy Operation, Failure to Start |

| Maintenance Tips | Regular Cleaning, Checking Wiring, Lubrication |

| Lifespan | 10 to 15 years |