In today's heating and cooling industry, the importance of reliable and efficient systems cannot be overstated. Among the critical components of modern furnaces, the "Inducer Motor Furnace" plays a pivotal role in ensuring optimal performance and safety. According to the U.S. Department of Energy, over 30% of residential energy consumption is attributed to heating and cooling systems, highlighting the necessity of efficient furnace operation.

However, many homeowners and technicians encounter common issues with inducer motors, which can lead to increased energy costs and system failures. A report from the HVACR Research Institute indicated that nearly 20% of service calls related to furnace malfunctions involved problems with the inducer motor. Understanding these common issues and their solutions is essential for maintaining system integrity and achieving energy efficiency.

In this blog, we aim to delve into the prevalent challenges associated with inducer motors in furnaces and offer practical tips for troubleshooting and maintenance.

Inducer motors play a crucial role in the efficient operation of furnaces, but they can encounter various issues that affect performance. Common symptoms indicating problems with inducer motors include unusual noises, decreased airflow, and frequent cycling of the furnace. If you notice any strange sounds, such as grinding or squeaking, it may suggest that the motor bearings are worn out or that there is a buildup of debris impeding its function. This should be addressed promptly to avoid further damage.

Another key symptom of inducer motor issues is a significant reduction in airflow. If your furnace feels less effective and takes longer to heat the space, the inducer motor may not be functioning optimally. Ensure that air filters are clean and that no obstructions are present in the intake ducts, as these can exacerbate motor strain.

Tip: Regular maintenance checks on your furnace can help identify potential inducer motor issues before they escalate. Keep an eye out for any warning signs, and don’t hesitate to consult with a professional if you suspect your inducer motor is malfunctioning. Taking proactive measures can improve both efficiency and longevity of your heating system.

A faulty inducer motor can significantly impact furnace performance, often leading to a range of operational issues. The inducer motor plays a crucial role in drawing combustion gases through the heat exchanger and out the flue. When this component fails or operates inefficiently, it can disrupt the proper ventilation of gases, which not only affects heating efficiency but can also pose serious safety risks. Consequently, homeowners may experience inadequate heating and increased fuel consumption, as the furnace works harder to maintain set temperatures.

A faulty inducer motor can significantly impact furnace performance, often leading to a range of operational issues. The inducer motor plays a crucial role in drawing combustion gases through the heat exchanger and out the flue. When this component fails or operates inefficiently, it can disrupt the proper ventilation of gases, which not only affects heating efficiency but can also pose serious safety risks. Consequently, homeowners may experience inadequate heating and increased fuel consumption, as the furnace works harder to maintain set temperatures.

Moreover, a malfunctioning inducer motor can lead to premature wear on other critical components of the furnace. For instance, if the motor fails to create the necessary airflow, it can cause overheating, which might damage the heat exchanger. This can result in costly repairs or even the need for a complete furnace replacement. Identifying symptoms of a faulty inducer motor early—such as unusual noises, excessive cycling, or error codes on the thermostat—can help prevent these issues from escalating and ensure the system operates efficiently and safely. Regular maintenance and inspections are essential in prolonging the life of the inducer motor and enhancing overall furnace performance.

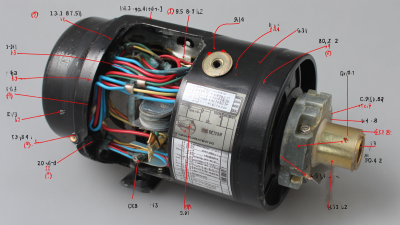

Inducer motors play a crucial role in the efficient operation of gas furnaces, yet they can encounter several common issues that may hinder performance. When troubleshooting these motors, it is essential to follow a step-by-step approach.

First, check the power supply and wiring connections. Ensure that the inducer motor is receiving the appropriate voltage and that there are no loose or frayed wires that could disrupt its operation.

Next, inspect the motor for any signs of physical damage or wear. Listen for unusual noises, like grinding or squeaking, which could indicate a failing bearing. Additionally, ensure that the motor is clean and free from debris that could obstruct airflow.

If the motor is not functioning, testing the capacitor and switches can help identify any electrical issues. By following these steps, you can efficiently diagnose the problems with your inducer motor and ensure your furnace operates smoothly and safely.

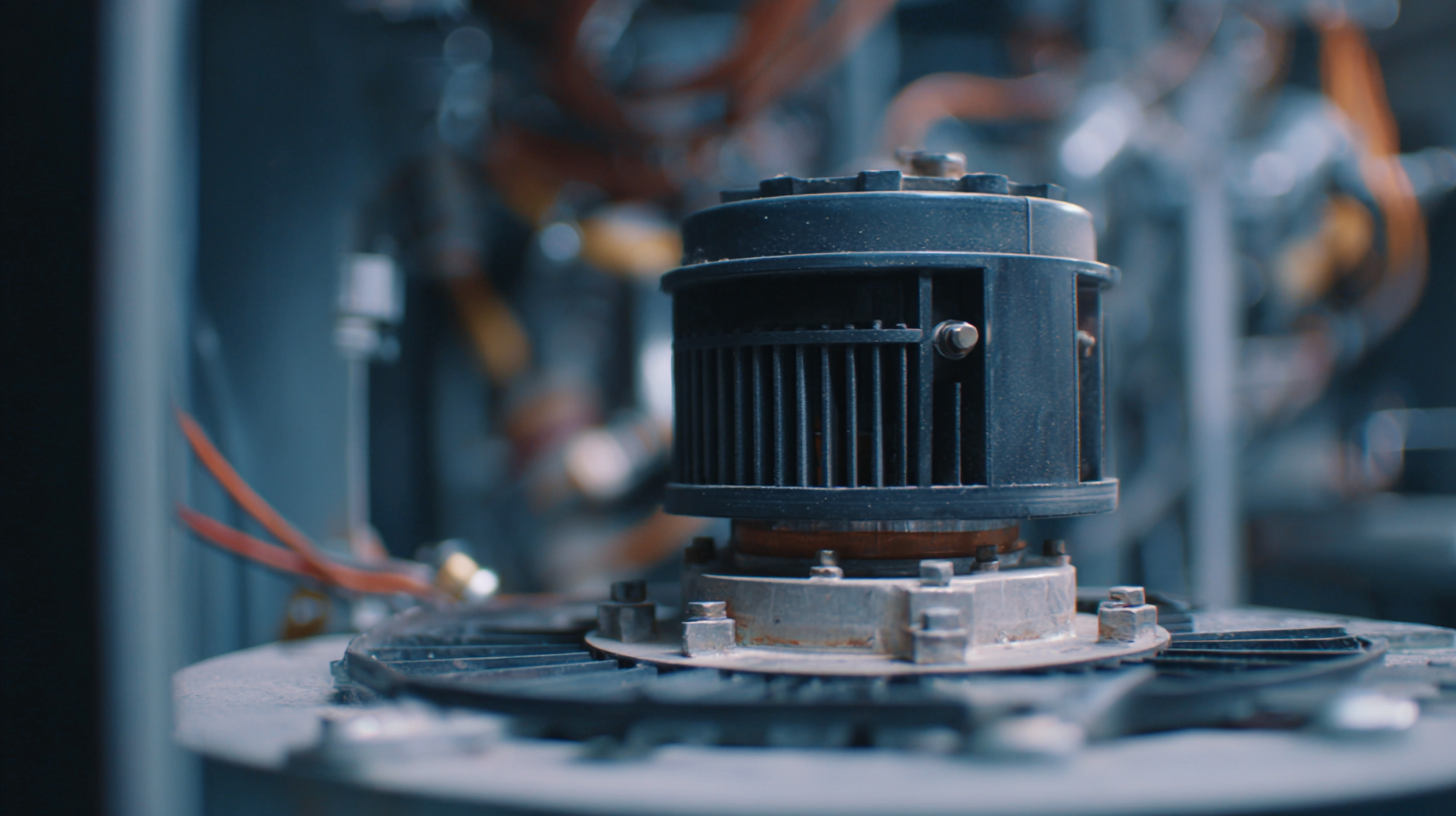

Inducer motors play a crucial role in the efficient operation of furnaces by ensuring proper airflow and combustion processes. To prolong the lifespan and optimize the performance of these essential components, implementing preventive maintenance is key. Regular inspections are vital; check for any signs of wear, such as excessive noise or vibration, which can indicate underlying issues. Additionally, ensure that the motor is free from dust and debris, as these can hinder performance and lead to overheating.

Lubrication is another important aspect of maintenance. Inducer motors often have bearings that require grease to prevent friction and extend their service life. Be sure to follow the manufacturer's guidelines regarding lubrication intervals and types of grease used. Furthermore, monitoring the electrical connections is essential; loose or corroded connections can disrupt the motor's operation and cause premature failure. By staying proactive with these maintenance tips, furnace owners can significantly enhance the longevity and reliability of their inducer motors, ensuring safe and efficient heating throughout the colder months.

Inducer motors play a pivotal role in the operation of furnaces by ensuring that adequate air supply is provided for combustion and that exhaust gases are effectively expelled from the system. These motors run a fan that helps facilitate the combustion process, making them essential for both safety and efficiency in heating systems. Without a properly functioning inducer motor, a furnace may struggle to operate effectively, leading to potential safety hazards such as improper venting of gases and reduced heating performance.

Tips for maintaining your inducer motor include regularly inspecting the motor for any signs of wear or damage, as well as ensuring the fan is free of obstructions. A clean and well-maintained inducer motor can prevent costly repairs and enhance the furnace’s longevity. Additionally, consider scheduling annual professional inspections to identify any issues early on, which can help avoid unexpected breakdowns during the cold winter months.

Understanding how your furnace’s inducer motor functions is essential for effective troubleshooting and repairs. Familiarizing yourself with this component can not only help you recognize when there’s a problem, but also empower you to make informed decisions regarding maintenance and upgrades for optimal furnace operation.