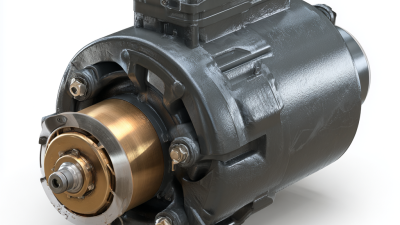

Furnace Motors play a critical role in heating systems. They ensure warm air circulates efficiently throughout your home. However, like any mechanical device, they can encounter issues over time. Homeowners often face common furnace motor problems that disrupt comfort and efficiency.

Understanding these issues is essential. Malfunctioning furnace motors can lead to increased energy bills and discomfort. You might notice strange sounds, poor airflow, or even complete failure. Each problem requires specific attention to resolve. Addressing these challenges early can save time and money.

In this guide, we will explore the top ten common furnace motor problems. Recognizing these signs is important. Solutions will also be provided. Take the time to reflect on your furnace's performance. Regular maintenance could prevent many of these issues.

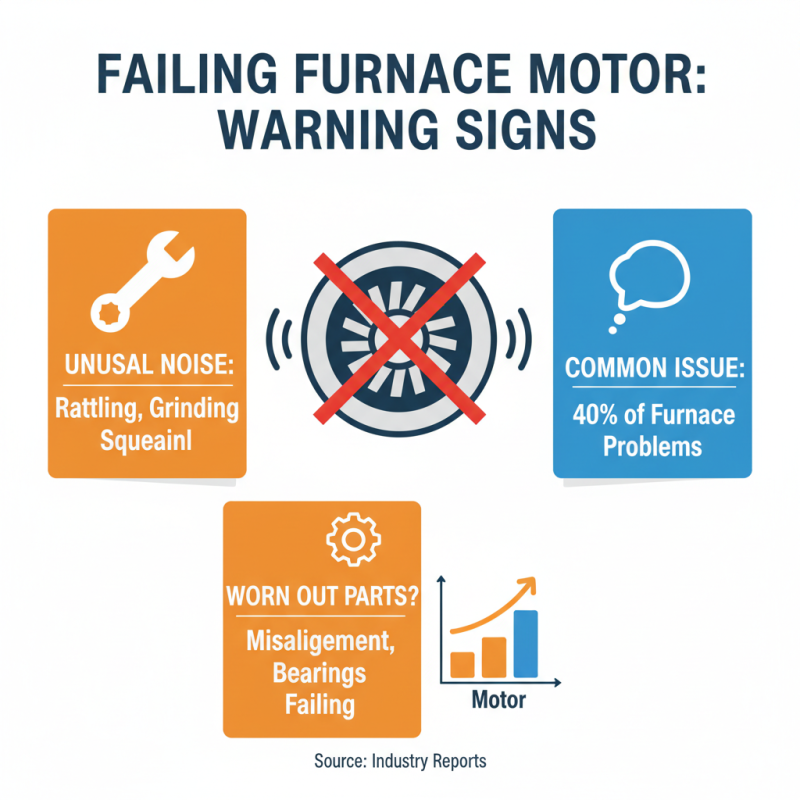

A failing furnace motor can present several noticeable signs. One common indicator is unusual noise. If your furnace produces rattling or grinding sounds, it might be time to investigate. Reports show that nearly 40% of furnace issues stem from motor malfunctions. Hearing these sounds suggests that components are wearing out or misaligned.

Another sign is inconsistent heating. If certain rooms are colder, the motor may struggle to circulate air effectively. Data from industry studies indicate that a malfunctioning motor leads to a performance drop of over 30%. This impacts comfort levels in your home significantly. Additionally, if the furnace frequently cycles on and off, this behavior indicates a motor issue.

Vibrations during operation can also be a cause for concern. A properly functioning motor should run smoothly. If you feel significant vibrations, something might be wrong internally. It's essential to address these signs promptly. Ignoring them could worsen the problem and lead to costly repairs. Pay attention to these warning signs to ensure your furnace operates efficiently.

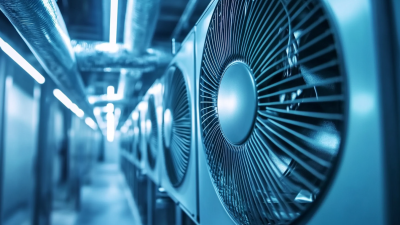

Furnace motors are crucial for heating systems. When they fail, it can cause discomfort and rising energy bills. One common issue is overheating. This can happen due to a dirty air filter or blocked vents. Regular maintenance helps prevent this problem.

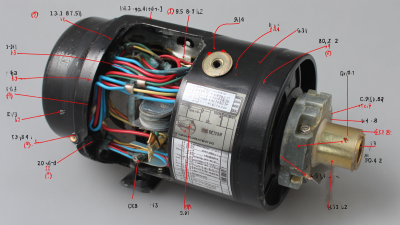

Another frequent cause of failure is electrical issues. Worn-out wiring or faulty connections can disrupt the motor's operation. It’s essential to check for frayed wires often. Additionally, lack of lubrication can lead to motor strain. This results in loud noises and decreased efficiency. Using appropriate lubricants on moving parts is vital.

Lastly, improper installation can create undue stress on the motor. Over time, this can lead to premature breakdowns. Homeowners should ensure that professionals handle installations. Regular inspections can help identify these issues early. Neglecting these problems often leads to costly repairs. Taking proactive steps can prolong the life of your furnace motor significantly.

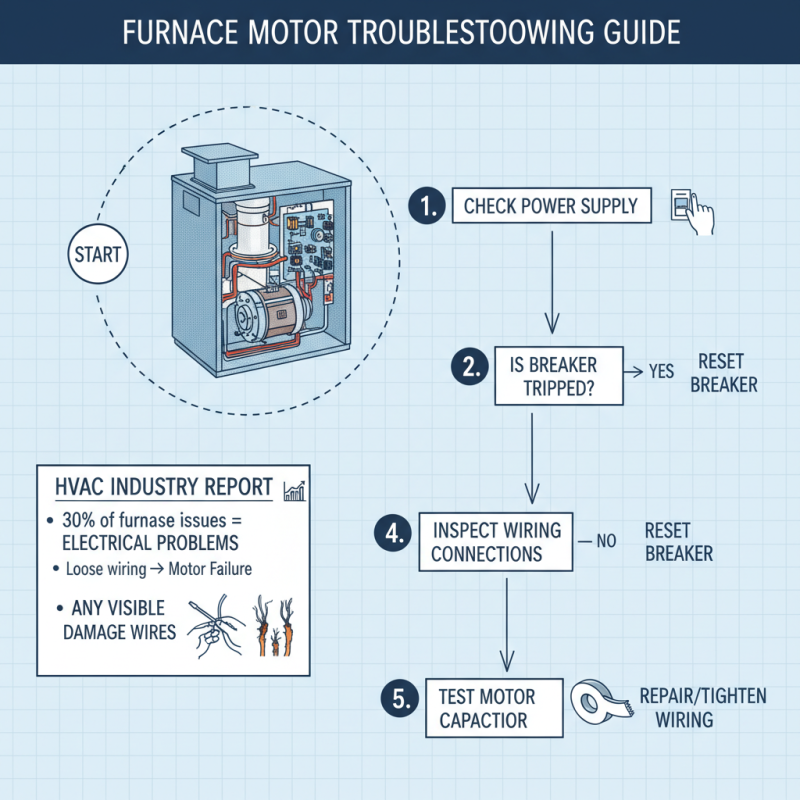

When troubleshooting furnace motors, a systematic approach is essential. Start by checking the power supply. Ensure the circuit breaker is not tripped. According to a recent HVAC industry report, around 30% of furnace issues stem from electrical problems. Inspect the wiring connections for signs of wear or damage. Loose wiring can lead to motor failure.

Listen for unusual noises. A grinding sound might indicate that the motor bearings are worn. In some cases, lubrication can help extend the motor’s life. However, if the noise persists, consider seeking professional help. Remember, it’s crucial to maintain clean filters. Dirty filters can hinder airflow, causing motors to overheat.

Tips: Regular maintenance can prevent many issues. Change filters monthly during peak seasons. In addition, ensure the furnace is free from dust buildup. It’s a simple step that enhances efficiency. Avoid ignoring small problems. They can escalate into larger issues. These oversights not only increase repair costs but can also affect energy bills significantly.

Furnace motors play a crucial role in maintaining comfortable indoor temperatures. However, they can encounter several common issues. One frequent problem is unusual noises. Grinding or squeaking sounds often indicate worn bearings. Regular lubrication might help, but sometimes replacement is the only solution.

Another common issue is overheating. If the motor is too hot to touch, it may indicate a clogged air filter. Change filters regularly to improve airflow and reduce strain. Additionally, electrical issues like tripped breakers can disrupt the motor's operation. Inspect wiring and connections for any signs of damage. A proactive approach can prevent larger problems in the future.

Lastly, intermittent operation can frustrate homeowners. This might occur due to a faulty capacitor. A simple test can reveal if the capacitor needs replacing. Sometimes the solution is easier than it seems. Investing time in regular maintenance can greatly extend the lifecycle of your furnace motor.

Regular maintenance is essential for keeping furnace motors running smoothly. Clean the motor regularly to prevent dust buildup. Dust can strain the motor, leading to overheating. Check the belts and pulleys for wear and tear. Worn parts can cause inefficiencies and require replacement.

Lubrication is another crucial aspect of maintenance. Use the right lubricant to keep the motor running quietly. A squeaky motor often indicates that it needs lubrication. Inspect the electrical connections as well. Loose wires can lead to power issues, putting unnecessary stress on the motor.

Consider scheduling professional check-ups annually. They can identify potential problems early. Ignoring small issues can lead to expensive repairs later. Even simple tasks like changing air filters can improve efficiency. Neglect can turn small fixes into significant headaches. Maintain a checklist to ensure every part is attended to.