Choosing the right Desiccant Filter is essential for maintaining efficiency in various applications. A well-suited filter can enhance the lifespan of equipment and improve product quality. However, the decision-making process is not always straightforward.

Many factors come into play when selecting a Desiccant Filter. Think about the desired humidity levels and the environment in which it will be used. Are other filtration needs being addressed? This choice is not merely technical; it also requires understanding nuances in operation. Each application presents unique challenges. Often, users overlook specific details such as airflow rates or moisture load.

Choosing poorly can lead to inefficiencies and increased costs. Users may settle for a filter that does not meet their specifications. In this regard, an analytical approach is crucial. Reflecting on past experiences can guide better decisions. Understanding your needs will empower you to choose a Desiccant Filter that truly fits your requirements.

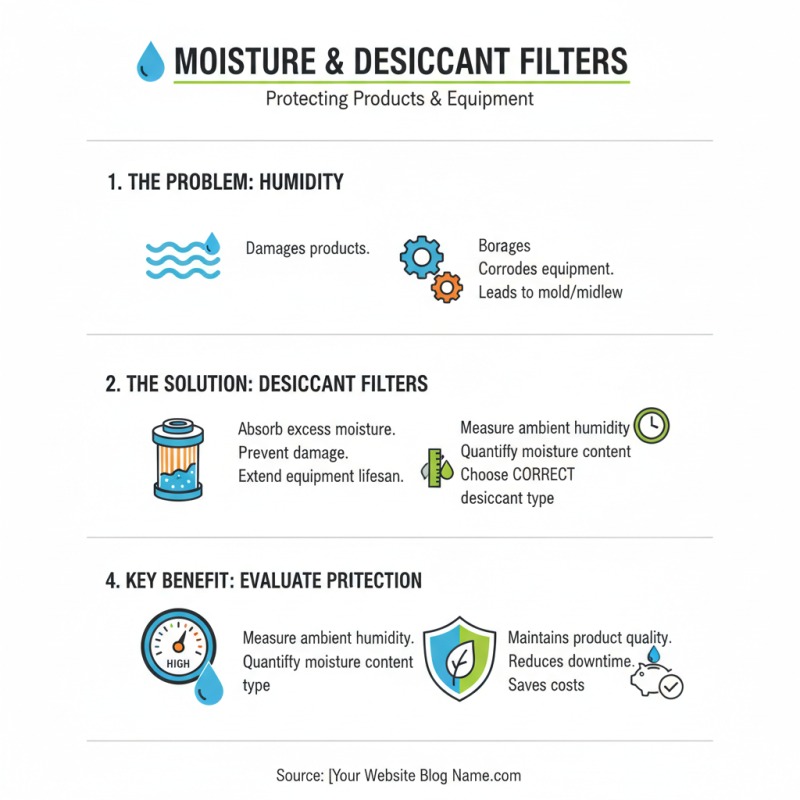

Desiccant filters play a pivotal role in various industrial processes. They remove moisture from gases and liquids, ensuring product quality and equipment longevity. According to a recent industry report, around 80% of machinery failures are caused by moisture-related issues. Thus, selecting the right desiccant filter is critical for minimizing downtime.

In many applications, desiccant filters enhance operational efficiency. In the pharmaceutical industry, for instance, proper moisture control is vital. A study indicated that moisture can degrade the potency of certain drugs by up to 30%. Similarly, in food processing, excess humidity can lead to spoilage, costing the industry millions annually. Using the right desiccant can save these costs.

While many manufacturers offer various options, users often overlook specific needs. Some may seek high moisture absorption but ignore regeneration capabilities. Others might choose cheaper filters, compromising on performance. The goal should be a balance between cost and efficiency. It's essential to evaluate the specific application. Understanding the unique requirements leads to better choices in desiccant filters.

When selecting a desiccant filter, several key factors need to be considered. Notably, the moisture adsorption capacity is crucial. According to the International Desiccant Institute, effective desiccants can absorb up to 30% of their weight in moisture. Choosing one with the right capacity for your specific conditions is essential. For instance, in high-humidity environments, a filter with greater adsorption capabilities may be necessary to maintain desired dryness levels.

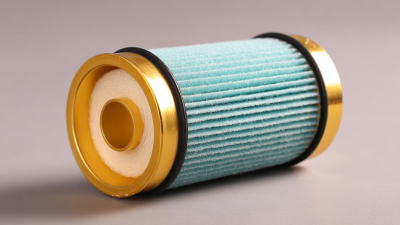

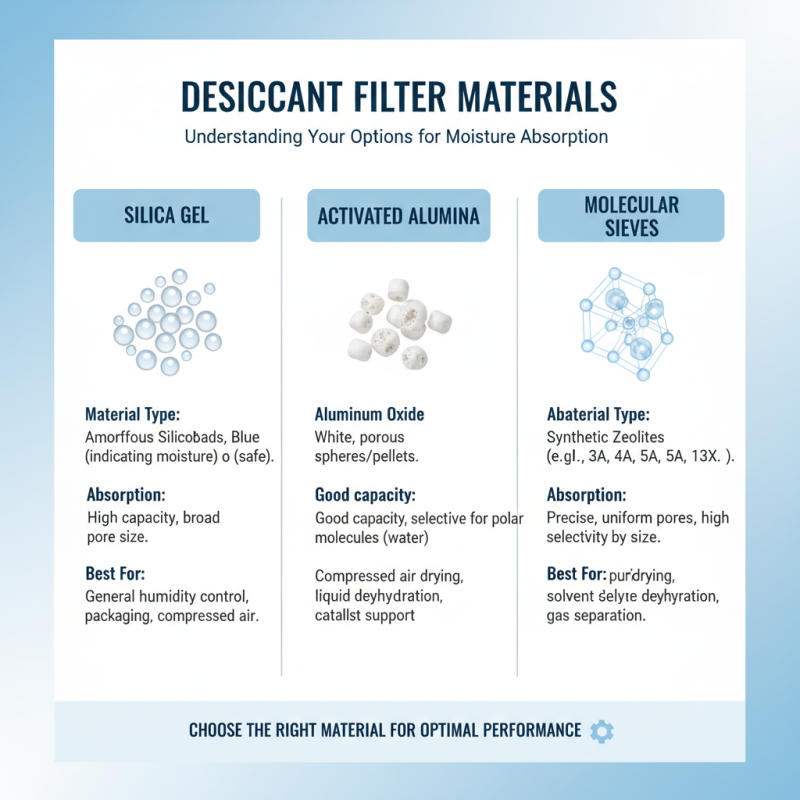

Another critical factor is the type of desiccant material used. Common materials include silica gel, activated alumina, and molecular sieves. Each has its strengths and weaknesses. For example, silica gel is popular due to its high moisture capacity and low cost. However, it can become less effective when saturated, potentially leading to moisture breakthrough. This is a risk you should weigh against the operational context and the potential for needing more frequent replacement.

Consider the filter's airflow resistance as well. A filter that improves air quality while maintaining low pressure drop is ideal. A report by the Air Filtration Association suggests that filters with lower resistance lead to improved energy efficiency. However, filters with high efficiency might come with increased resistance, leading to higher energy costs. Balancing efficiency and operational costs requires careful consideration of your specific application and needs.

| Criteria | Description | Considerations |

|---|---|---|

| Material Type | The composition of the desiccant filter, commonly silica gel, activated alumina, or molecular sieves. | Choose based on the moisture level and specific application. |

| Moisture Capacity | The amount of moisture the filter can absorb before it becomes saturated. | Ensure it meets the demands of the environment where it will be used. |

| Regeneration Method | How the desiccant can be reused, either through heat or chemical methods. | Consider ease of regeneration depending on your operating conditions. |

| Filtration Efficiency | How effectively the filter removes moisture and contaminants from the air. | Higher efficiency may be required for sensitive equipment or processes. |

| Cost | The initial purchase price and ongoing maintenance costs of the filter. | Balance upfront costs against long-term efficiency and performance. |

When selecting a desiccant filter, understanding the materials is crucial. Common options include silica gel, activated alumina, and molecular sieves. Each material has unique properties that impact its effectiveness in moisture absorption.

Silica gel is widely known for its high absorption capacity. It can hold approximately 40% of its weight in moisture. However, it becomes less effective at higher humidity levels. Activated alumina, on the other hand, excels in high humidity conditions. It can capture water at various temperatures, making it versatile. Yet, it may not perform as well when high purity is required.

Molecular sieves are another option. They are structured to trap specific molecules, offering precise control over humidity levels. While they provide excellent results, they can be costly. Choosing a desiccant filter is not straightforward. Each material has benefits and drawbacks. Users must consider factors like application conditions and desired moisture levels. Knowing your needs will guide you in making the right choice.

Evaluating moisture levels is crucial in choosing the right desiccant filter. Humidity can damage products and equipment. High moisture levels can lead to corrosion. It's vital to measure the moisture content in your environment.

Use a hygrometer for accurate readings. This device will help you understand the humidity levels. You may find that an area is more humid than you anticipated. It’s essential to reassess your needs regularly. A misunderstanding of moisture levels could lead to using inadequate filters.

Tips: Consider seasonal changes. Humidity can fluctuate, affecting your choice. You might need different filters for summer and winter. Ensure your filter matches the moisture levels you measured. Check frequently for efficiency. Don’t let moisture compromise your work.

Maintaining desiccant filters is crucial for optimal performance. A well-maintained filter can enhance efficiency and longevity. Regular inspection should be a priority. Look for dirt buildup or moisture accumulation. These issues can hinder functionality.

Tips: Check filters monthly. Replace any that show signs of damage. Even minor wear can lead to bigger problems later on.

Another best practice is to ensure proper installation. An incorrectly installed filter may not perform efficiently. Follow the installation guidelines closely. If unsure, seek assistance from a knowledgeable source.

Tips: Keep an installer’s manual handy. Document any maintenance actions taken for future reference.

Lastly, monitor environmental conditions. Extreme temperatures or high humidity can affect filter lifespan. Make adjustments based on your specific needs. Always be proactive about potential challenges.

Tips: Use a humidity gauge. Regularly assess your environment. Adjust as needed to maintain ideal conditions.