Selecting the appropriate Furnace Fan Motor for your heating system is essential for optimizing energy efficiency and system performance. According to the U.S. Department of Energy, approximately 29% of energy consumption in residential buildings is attributed to heating, indicating that an efficient heating system is critical for reducing utility costs. A well-chosen Furnace Fan Motor not only enhances the airflow and comfort within your home but also contributes to maintaining a consistent temperature. Industry reports suggest that using the correct motor can improve heating system efficiency by up to 20%.

Selecting the appropriate Furnace Fan Motor for your heating system is essential for optimizing energy efficiency and system performance. According to the U.S. Department of Energy, approximately 29% of energy consumption in residential buildings is attributed to heating, indicating that an efficient heating system is critical for reducing utility costs. A well-chosen Furnace Fan Motor not only enhances the airflow and comfort within your home but also contributes to maintaining a consistent temperature. Industry reports suggest that using the correct motor can improve heating system efficiency by up to 20%.

With various options available, understanding the specifications and capabilities of Furnace Fan Motors is crucial for homeowners aiming to make informed decisions about their heating solutions. By focusing on factors such as compatibility, motor type, and efficiency ratings, you can significantly enhance your heating system's performance and reliability.

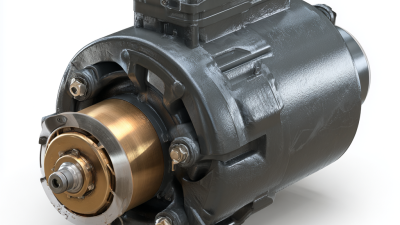

When selecting a furnace fan motor, it's essential to understand the different types available to ensure optimal performance in your heating system. The most common types of furnace fan motors include permanent split capacitor (PSC), shaded pole, and ECM (electronically commutated motors). PSC motors offer efficient power consumption while providing consistent airflow, making them a popular choice in many residential systems. They operate quietly and have a longer lifespan compared to traditional motors.

Shaded pole motors, while less efficient, are simple and cost-effective solutions typically found in smaller heating systems. They are easy to install but can consume more energy over time, leading to higher operational costs. On the other hand, ECMs are known for their energy efficiency and variable speed capabilities. These motors adjust their speed to the heating demands of the home, providing superior comfort and reducing energy consumption. Understanding these differences allows homeowners to make informed decisions when choosing the right furnace fan motor tailored to their specific heating requirements.

When selecting the right furnace fan motor for your heating system, several key factors come into play to ensure optimal performance and efficiency. First and foremost, understanding the motor’s horsepower is crucial. According to the U.S. Department of Energy, properly sized motors can reduce energy consumption by up to 20%. It's essential to match the motor's horsepower to the demands of your heating system to avoid overworking the motor and increasing energy costs.

Another important consideration is the motor's efficiency rating. Motors with a higher efficiency rating, usually marked as ECM (Electronically Commutated Motors), can significantly cut down on energy use compared to standard models. The Consortium for Energy Efficiency notes that upgrading to a high-efficiency motor can lead to a return on investment within just a few years due to the considerable energy savings. Additionally, assessing the noise levels produced by different motors is vital, as quieter operations contribute to overall comfort within the home. Taking these factors into account will guide you in choosing the right furnace fan motor that aligns with both your heating system’s needs and your energy conservation goals.

When selecting a furnace fan motor, determining the right size and compatibility with your heating system is crucial. A properly sized motor ensures efficient airflow, which is essential for optimal heating performance. According to the U.S. Department of Energy, an appropriately sized furnace fan can improve energy efficiency by up to 30%. To assess the right size, you should consider the cubic feet per minute (CFM) rating required for your specific heating system; typically, a CFM range of 400-600 is standard in residential applications.

Compatibility is equally important when choosing a furnace fan motor. Factors such as voltage, horsepower, and mounting type must align with your existing system to ensure seamless integration. Industry reports suggest that mismatched motors can lead to overheating or early failure, resulting in costly repairs. Before making a purchase, consult your furnace's specifications and consider reaching out to a local HVAC professional to confirm the compatibility of potential motor options with your system.

| Motor Type | Horsepower (HP) | Voltage (V) | RPM | Compatibility | Efficiency Rating |

|---|---|---|---|---|---|

| Single-Phase | 1/3 HP | 115V | 1075 RPM | Standard Residential Furnaces | 80% |

| Three-Phase | 1 HP | 230V | 1800 RPM | Commercial Heating Systems | 90% |

| ECM Motor | 1/2 HP | 120V | 1200 RPM | Variable Speed Systems | 95% |

| Permanent Split Capacitor | 1/4 HP | 115V | 1075 RPM | Standard Residential Furnaces | 75% |

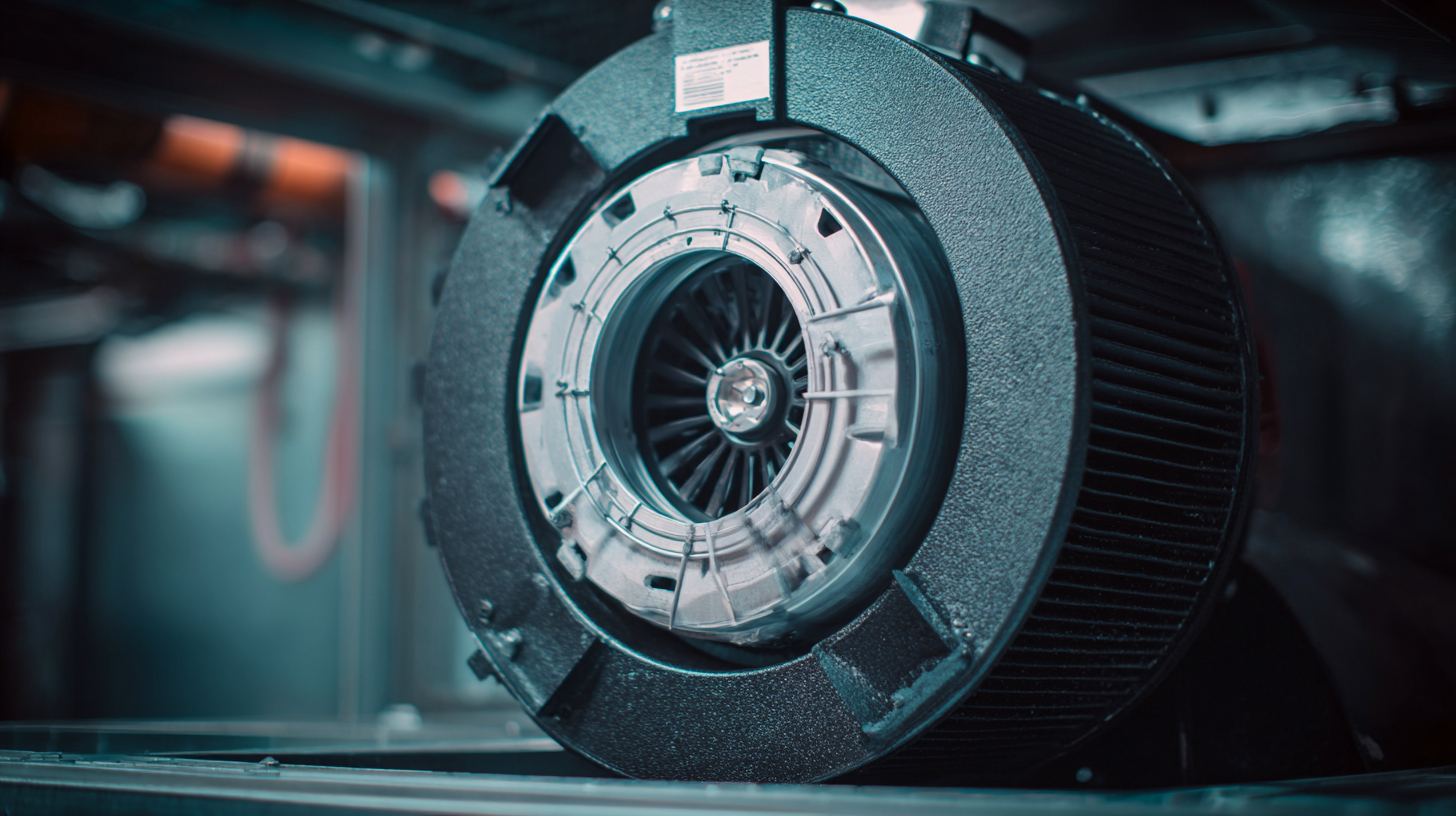

When selecting a furnace fan motor, evaluating energy efficiency and performance ratings is crucial. According to the U.S. Department of Energy, HVAC systems consume about 50% of a home's energy use, making it imperative to choose a motor that maximizes efficiency. Fan motors come in two primary types: permanent split capacitor (PSC) and electronically commutated motors (ECM). ECMs are known for their superior efficiency, often achieving ratings above 85%, compared to PSC motors, which typically hover around 60-70%. This efficiency translates not only to lower monthly utility bills but also to improved overall HVAC performance.

Performance ratings, such as airflow measurement in cubic feet per minute (CFM), should also be considered. A motor that operates efficiently at higher CFM can lead to better heat distribution throughout a home, enhancing comfort levels. As reported by the Air Conditioning, Heating, and Refrigeration Institute (AHRI), high-performance fan motors can significantly reduce energy consumption during peak heating seasons. Thus, selecting a motor with an appropriate efficiency rating and adequate airflow capacity is vital for ensuring a well-functioning heating system that is both cost-effective and environmentally friendly.

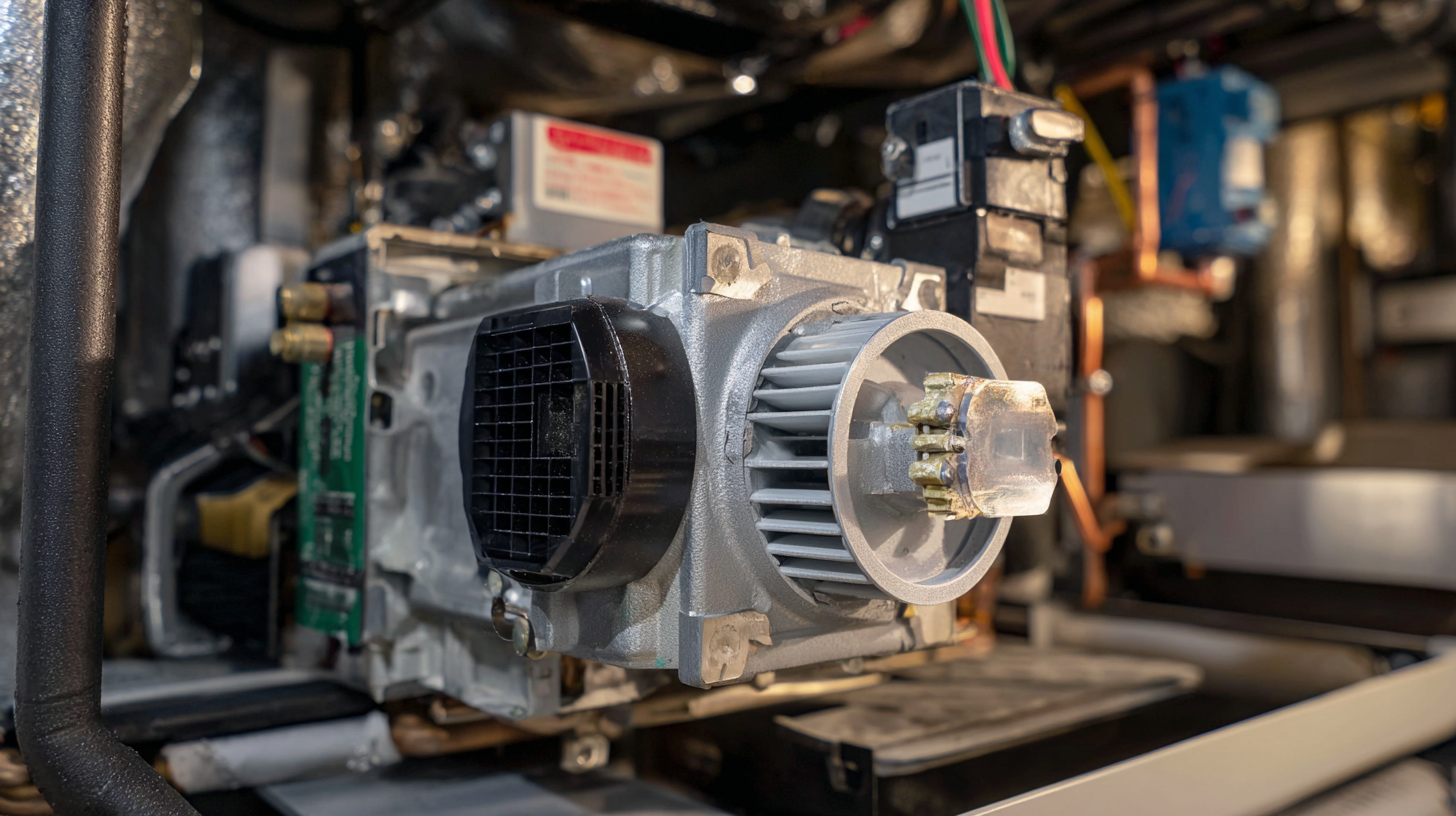

Installing and maintaining your chosen furnace fan motor properly is crucial for the efficient functioning of your heating system. According to a report from the Department of Energy, poor installation and maintenance can reduce a unit’s efficiency by over 30%. Therefore, it is vital to follow the manufacturer's guidelines during installation, ensuring that the motor is compatible with your existing furnace system. Proper wiring connections, secure mounting, and correct fan alignment should be prioritized to avoid operational issues.

Regular maintenance plays a key role in extending the lifespan of your furnace fan motor. The National Renewable Energy Laboratory recommends performing routine checks every six months, focusing on cleaning the motor and checking for any wear on parts. A well-maintained motor can help prevent premature failures and costly repairs.

Tips: Always keep an eye on strange noises or vibrations, as these can indicate potential problems. Using vibration analysis can be an effective way to detect these issues early, preventing misalignment before it escalates into a major malfunction. Moreover, don't forget to lubricate the motor bearings regularly, as this simple step can reduce friction and prevent overheating.