Selecting the right Desiccant Filter is crucial for optimal performance. Renowned expert Dr. Sarah Millen once stated, "The right desiccant filter can save costs and enhance efficiency." Understanding your specific needs is vital in this process.

There are various desiccant filters available, each designed for different applications. Some filters excel at moisture removal in industrial settings, while others cater to residential use. It can be confusing to navigate through the options. Without proper knowledge, choosing one can lead to inefficiencies.

Many underestimate the importance of performance metrics. A filter may look good on paper but fail in real-world applications. Transparency in the specifications is often lacking. It's essential to scrutinize product claims and understand actual performance under various conditions. Reflecting on past mistakes in filter selection can provide valuable insights for future decisions.

Desiccant filters play a crucial role in moisture control across various industries. These filters help protect sensitive equipment and products from damage caused by humidity. According to a recent industry report, humidity can reduce the lifespan of electronic components by up to 30%. This highlights the importance of choosing the right desiccant filter to manage moisture effectively.

Understanding how desiccant filters work is essential. They contain materials that absorb moisture from the air. Common desiccants include silica gel and activated alumina. Their efficiency can vary based on environmental conditions. In a study published by the International Journal of Industrial Technology, it was shown that specific filters can remove up to 95% of moisture at optimal conditions. However, under high humidity, their performance may not match expectations.

Selecting a desiccant filter requires consideration of several factors. Capacity, activation temperature, and humidity levels affect performance. Not all filters are created equal. For example, some may need frequent replacements in humid areas, which can lead to increased costs and downtime. A careful assessment of your specific needs is crucial to ensure effective moisture control.

When selecting desiccant filters, consider the humidity levels in your environment. High humidity might require a more robust filter. Analyze the specific needs of your application. For instance, industrial settings often demand higher moisture removal capabilities than residential ones.

Pay attention to the filter's capacity. Some filters can hold more moisture than others. Look into the material composition too. Certain materials may perform better in different temperatures or pressures. Don't underestimate the importance of ease of maintenance. Filters that are hard to replace or clean can lead to complications later.

Evaluate the cost versus the lifespan of the desiccant filter. A cheaper option may not last as long. Reflect on your installation space. Filters that are too large or cumbersome can create installation challenges. Make sure to read customer reviews or case studies. Sometimes, you'll notice common issues or praises for specific models, which can guide your choice.

When choosing a desiccant filter, understanding the materials is crucial. Various types of desiccant materials are available, such as silica gel, activated alumina, and molecular sieves. Each has unique properties suited for different applications.

Silica gel absorbs moisture effectively in moderate humidity environments. It is commonly used in packaging to keep products dry.

Activated alumina is another excellent choice. It can adsorb both moisture and certain gases. This feature makes it ideal for air and gas filtration systems. Its ability to withstand high temperatures adds to its versatility.

Molecular sieves are specialized materials. They excel in removing specific sizes of molecules, making them useful in industrial applications.

Tips: Consider your environment. High humidity? Silica gel might be best. For specialized needs, research specific requirements. Layering different desiccants can enhance efficiency. Each type has constraints. Not every filter suits every condition. Experiment to find the perfect match for your needs. Be willing to adjust your choices based on performance.

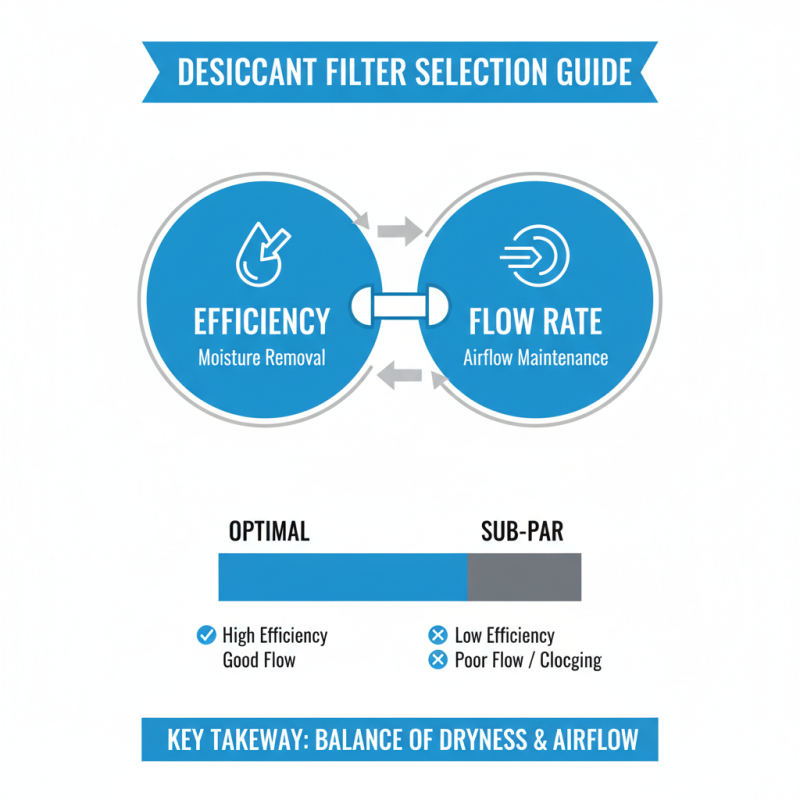

Choosing the right desiccant filter involves understanding specific performance metrics. Efficiency and flow rate are crucial factors. You want a filter that removes moisture effectively. It should maintain a good airflow to avoid clogging.

Airflow is often overlooked. Too much resistance can hamper efficiency. Ensure that the filter you choose balances these two metrics. A filter with higher efficiency may slow down airflow. This can cause a negative impact in many applications.

**Tip:** Look for filters with indicators. They show when the filter may be nearing its capacity. This helps in planning maintenance.

Another aspect is the initial cost versus long-term efficiency gains. Some may save upfront costs but lead to higher energy expenses later. Assess your needs carefully.

**Tip:** Consider a filter’s operating environment. Dusty or humid areas require different solutions. Matching the filter to its environment optimizes performance.

Choosing wisely can seem overwhelming. Reflect on your specific situation and needs. The right decisions often come from careful evaluation.

When evaluating desiccant filters, cost-effectiveness is a crucial factor. A lower initial price may seem appealing. However, the lifespan of the filter often determines overall value. Short-lived filters lead to frequent replacements. This can add up quickly over time. Many users overlook this aspect. They focus solely on upfront costs.

Longevity is equally important when selecting a desiccant filter. Consider how often you need to replace it. Filters with longer lifespans can save money in the long run. Additionally, maintenance requirements can impact costs. Easy-to-replace filters may reduce downtime and labor costs. Yet, this might not always be apparent at the time of purchase.

Think about the specific needs of your environment. Humidity levels and application types vary widely. Some filters perform better in certain conditions. Assessing these factors may take time. It's easy to make mistakes if you rush the decision. Planning carefully leads to better long-term satisfaction. Often, the best choice is not the most obvious one.