When selecting an air dryer filter for optimal performance and longevity, it is essential to consider various factors that contribute to the overall efficiency of compressed air systems. According to the Compressed Air and Gas Institute (CAGI), improper filtration can lead to up to 30% energy loss in compressed air operations, which significantly impacts operational costs and equipment lifespan. Understanding the specific needs of your system and the requirements of various filter types can make a considerable difference in maintaining air quality and system reliability.

Air dryer filters play a crucial role in removing moisture, particulates, and contaminants from compressed air, ensuring that downstream equipment operates smoothly. A study by the International Society for Compressors and their Applications (ISCA) emphasizes that using the appropriate air dryer filter can extend the life of pneumatic machinery by over 25%. Therefore, selecting the right filter not only enhances performance but also reduces maintenance costs and the risk of equipment failure. With the ever-increasing demand for efficiency and sustainability in industrial operations, leveraging the insights from industry reports can guide decision-makers toward the best choices for air dryer filters that align with their operational goals.

Air dryer filters play a critical role in maintaining the overall performance and longevity of compressed air systems. They are essential in removing contaminants such as moisture, oil, and particulates from compressed air, which can otherwise lead to equipment failure and increased operational costs. According to a report by the Compressed Air and Gas Institute (CAGI), equipment can lose efficiency by up to 25% due to inadequate filtration, significantly impacting productivity and energy consumption.

When selecting an air dryer filter, one must understand the specific requirements of their system. Factors like flow rate, the type of contaminants present, and the environmental conditions all influence filter efficacy. A study from the International Society for Trenchless Technology highlights that maintaining clean air can lead to a reduction in energy usage by up to 15%, translating into substantial cost savings over time. Filters that are tailored to the unique demands of your application can improve reliability and extend the lifespan of other vital components within the system, making the choice of the right air dryer filter a key aspect of operational efficiency.

When selecting an air dryer filter, it's essential to consider key features that can significantly impact both performance and longevity. One pivotal aspect is the filtration efficiency. According to the Compressed Air and Gas Institute (CAGI), filters that achieve a 99.9% efficiency in particulate removal are integral in preventing contaminants from damaging sensitive equipment. This level of filtration not only extends the lifespan of air tools and compressors but also ensures optimal operation, especially in industry settings where clean air is crucial for production quality.

Another critical feature is the filter's flow rate. A study by the International Air Compressor Association (IACA) emphasizes that filters must be appropriately sized to match the flow requirements of the system they support. Oversized or undersized filters can lead to inadequate performance or increased maintenance costs. Additionally, features such as water separation capability and filtration media type (e.g., coalescing vs. particulate) should be carefully evaluated. Selecting a filter with robust water separation properties can reduce the risk of corrosion and equipment failure, further prolonging the operational lifespan of your air system.

| Filter Type | Particle Removal Efficiency | Pressure Drop | Temperature Rating | Replacement Interval (Months) | Cost ($) |

|---|---|---|---|---|---|

| Microfiber Filter | 99.97% @ 0.3 microns | Low | -20° to 80°C | 6 | 50 |

| Coalescing Filter | 99.99% @ 3 microns | Moderate | -10° to 60°C | 12 | 75 |

| Activated Carbon Filter | N/A | High | 0° to 50°C | 3 | 100 |

| Dust Filter | 90% @ 5 microns | Low | -20° to 70°C | 6 | 30 |

When it comes to selecting air dryer filters for optimal performance and longevity, industry reports emphasize the importance of efficiency in compressed air systems. According to a study by the Compressed Air and Gas Institute (CAGI), the right air dryer filter can enhance the lifespan of your equipment by reducing the contamination of moisture and particulates, which are prevalent in compressed air systems. Filters that adhere to stringent ISO 8573.1 standards are recommended, as they ensure the removal of harmful particles down to 0.01 micron, significantly decreasing the risk of corrosion and operational downtime.

Top air dryer filters, such as desiccant filters, coalescing filters, and activated carbon filters, have demonstrated enhanced efficiency in various applications. A report by the Air and Waste Management Association highlights that using a quality coalescing filter can achieve particle removal efficiencies of over 99.9%, while desiccant filters can achieve dew point levels as low as -40°F. Additionally, it's essential to consider the filter's design and maintenance requirements, as regular replacement is crucial for long-term functionality. Investing in higher-quality filters not only improves performance but also results in reduced energy costs, which are estimated to account for up to 70% of total operational expenses in compressed air systems.

When choosing the best air dryer filter, it is crucial to understand the different types available and their efficiencies. The two primary categories of air dryer filters are coalescing filters and desiccant filters. Coalescing filters are designed to remove water and particulates from compressed air by forcing the air through a fine media. This process effectively captures moisture, helping to prevent corrosion and damage to downstream equipment. Their efficiency levels can reach up to 99.9%, making them suitable for applications where clean, dry air is vital.

On the other hand, desiccant filters utilize a material that absorbs moisture, providing low dew points and ensuring that the air remains extremely dry. These filters are particularly beneficial in industries where humidity levels must be controlled strictly, such as pharmaceuticals and food processing. While desiccant filters may require more frequent replacements and maintenance, their performance in moisture-laden environments makes them indispensable.

Ultimately, the choice between these filter types hinges on specific operational requirements and the desired balance between performance and maintenance costs.

Maintaining your air dryer filter is crucial for ensuring its optimal performance and longevity. Regular maintenance not only helps to extend the life of your filter but also enhances the overall efficiency of your air dryer system. One essential tip is to schedule routine inspections. By checking your air dryer filter frequently, you can identify any signs of wear or contamination early on, preventing costly repairs or replacements down the line.

Another important aspect of maintenance is cleaning the filter. Depending on the type of filter you have, it may be possible to wash or blow out the dust and debris that accumulate over time. This simple practice can enhance airflow and reduce strain on your air dryer. Additionally, consider replacing disposable filters according to the manufacturer’s recommendations to ensure that the filter operates at peak efficiency.

Finally, always adhere to the manufacturer's guidelines regarding the appropriate type of filter for your specific air dryer model. Using the wrong filter could lead to inefficiency and decreased lifespan. By following these maintenance tips, you will not only prolong the life of your air dryer filter but also maintain the overall performance of your air system.

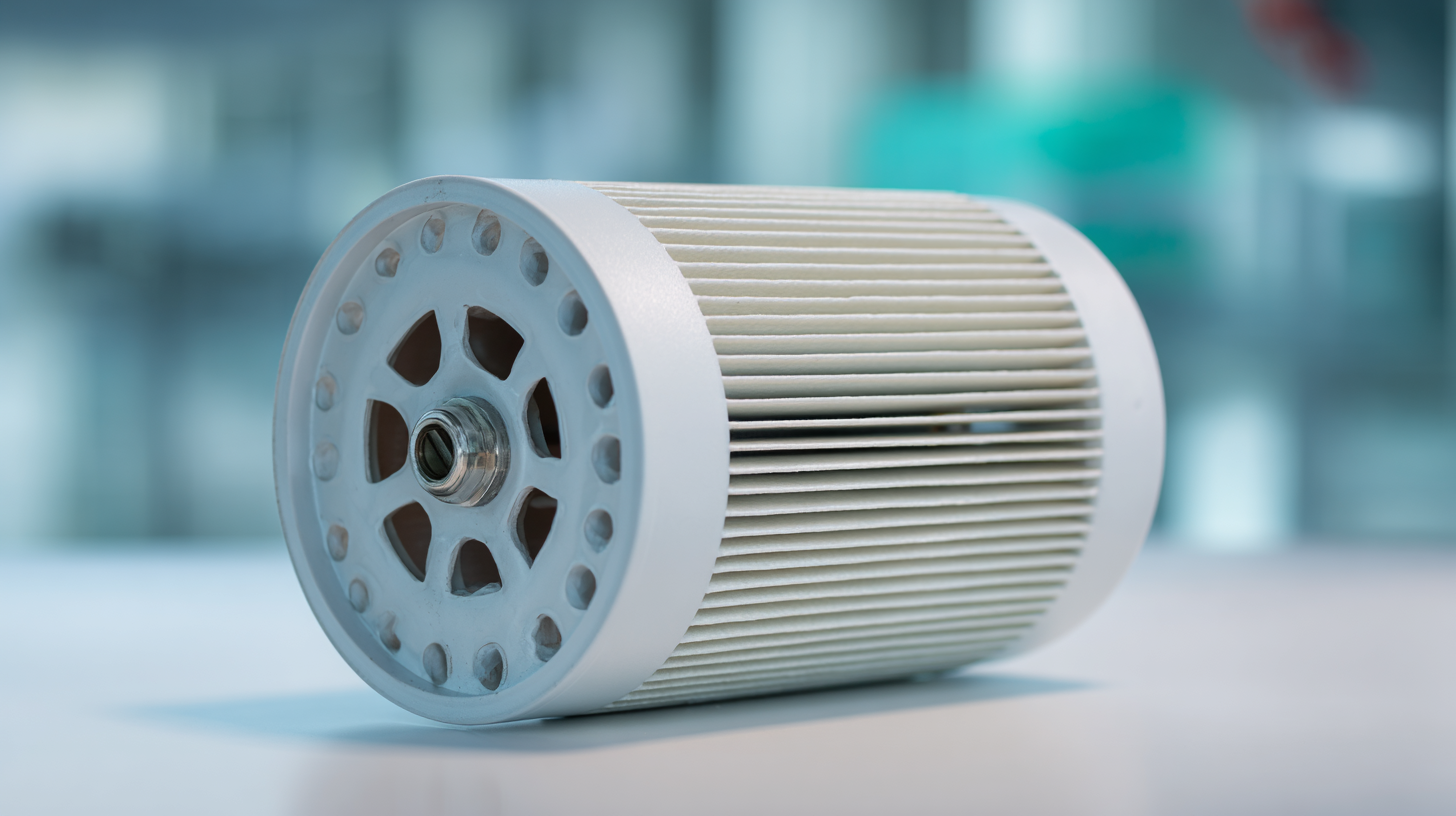

The chart above illustrates key factors impacting the performance and longevity of air dryer filters. As filter age increases, it is crucial to maintain optimal cleaning frequencies and monitor pressure drops to reduce replacement costs and enhance overall efficiency.