When it comes to plumbing, the right tools and components matter. An Access Valve plays a crucial role in maintaining your plumbing system. Understanding how to choose and install one can save you time and stress.

Selecting the perfect Access Valve involves considering various factors. You need to think about size, material, and location. Each aspect influences how effectively the valve works. A poorly fitted valve can lead to leaks or reduced functionality.

Installation is another key aspect. It requires careful attention to detail. If done incorrectly, even the best Access Valve can fail. Mistakes often happen due to rushed decisions or lack of knowledge. This guide aims to provide insight into the right choices and installation methods. By doing so, you'll enhance the reliability of your plumbing system.

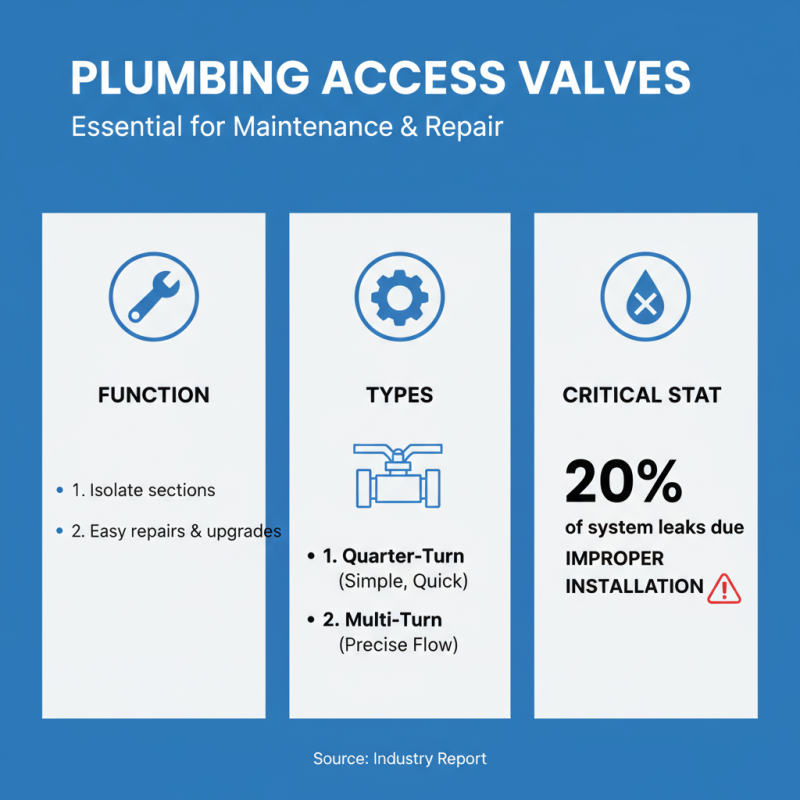

Access valves serve essential roles in plumbing systems. They allow for easy maintenance and repair of pipes. There are several types of access valves, each with specific functions and benefits. For instance, quarter-turn valves are popular for their simplicity. They offer quick access and are user-friendly. A recent industry report indicates that improper valve installation can lead to leaks in over 20% of systems.

Another common type is the blow-off valve, which helps in draining and purging systems. They are crucial for maintaining efficient plumbing functions. Choosing the right valve depends on the plumbing layout and specific needs. Often, homeowners overlook these details during installation, leading to costly mistakes. Research shows that nearly 30% of plumbing issues stem from inadequate access points.

In practice, many individuals struggle to identify the best fit for their needs. An access valve should balance accessibility with long-term reliability. Some users might install valves too close to walls, impacting functionality. This oversight can create unnecessary challenges for future repairs. Proper understanding of access valves can significantly enhance plumbing system performance.

Choosing the right access valve for plumbing requires careful consideration. The size of the valve is crucial. It should match the pipe diameter for optimal flow. If the valve is too small, it can restrict water flow. If it's too large, it may not fit properly. Always measure your pipes before making a decision.

Material is another key factor. Access valves come in various materials, such as PVC and brass. Each material has its own durability and resistance to corrosion. Consider your environment. If you live in a humid area, a corrosion-resistant valve may be necessary.

Installation is a critical step as well. Improper installation can lead to leaks or failures. Ensure you have the right tools. Read the manufacturer's instructions carefully. There may be common pitfalls that could easily be avoided. Take your time and double-check your work. Small mistakes can lead to big issues later on.

Installing an access valve can be straightforward if you follow a few simple steps. Begin by gathering your tools: a wrench, a utility knife, and some plumber’s tape. Make sure to have safety gloves and goggles ready. Choosing the right spot for your valve is crucial. It should be easy to access but not in the way of regular activities. Consider potential obstructions like pipes or fixtures nearby.

Once the location is determined, turn off the water supply. Mark the area where you will cut. Using a utility knife, make a precise cut in the pipe. This part can be tricky. Ensure your cut is level to avoid leaks later. After cutting, clean the edges thoroughly. Wrap plumber’s tape around the threads of your valve. This helps create a tight seal.

Next, install the valve by screwing it into place. Be cautious not to over-tighten it, as this may damage the threads. After securing it, turn the water supply back on slowly. Check for leaks around the valve. The process might not be perfect. Take your time and reflect on any mistakes. Proper installation can save you from future plumbing issues.

| Step Number | Action | Tools Required | Estimated Time |

|---|---|---|---|

| 1 | Select the Right Access Valve | None | 15 minutes |

| 2 | Gather Necessary Tools | Wrench, Screwdriver, Level | 10 minutes |

| 3 | Shut Off Water Supply | None | 5 minutes |

| 4 | Cut into Pipe | Pipe Cutter | 20 minutes |

| 5 | Install Access Valve | Wrench | 15 minutes |

| 6 | Check for Leaks | None | 10 minutes |

| 7 | Restore Water Supply | None | 5 minutes |

| 8 | Test Valve Function | None | 10 minutes |

Installing an access valve requires specific tools and materials. You'll need a wrench, a hacksaw, and Teflon tape. These essentials ensure a proper seal and fit. A recent industry report indicates that improper installation is a leading cause of plumbing issues, contributing to 29% of system failures.

In addition to tools, the right materials are crucial. A PVC or metal access valve is typically recommended. The choice depends on your plumbing system. Industry data shows that PVC valves are lighter and easier to install. However, metal valves may offer better durability in high-pressure systems. Understanding these options is vital for a successful installation.

Preparation is key. Make sure all tools are within reach before starting. This reduces the risk of errors during installation. Remember to check the valve dimensions to avoid mishaps. It's easy to overlook these details, which can lead to leaks or blockages. Following industry guidelines can help ensure a more reliable installation.

Access valves are crucial for plumbing systems. Ensuring their longevity requires regular maintenance and attention. Check the valve regularly for any signs of leaks or corrosion. A small leak can become a big problem if ignored. Pay attention to the surrounding area for water stains.

Cleaning the valve is essential. Use a damp cloth to remove dust and debris. Avoid harsh chemicals that could damage the valve material. Inspect seals and gaskets for wear. Replacing worn parts can extend the valve’s life. Sometimes it is easy to forget, but these small steps matter greatly.

Consider the environment around the valve. Extreme temperatures can affect performance. Insulate exposed pipes if necessary. If you notice anything unusual, do not hesitate to call a professional. Delaying repairs can cause bigger issues. A little care goes a long way in plumbing maintenance.