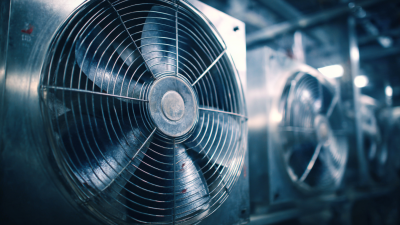

Choosing the right fan motors is a crucial decision that can significantly impact efficiency, performance, and longevity in various applications, from HVAC systems to industrial machinery. With a plethora of options available in the market, navigating through the technical specifications, energy ratings, and operational requirements can be overwhelming. This essential checklist aims to provide expert insights and industry data to help you make informed decisions when selecting fan motors for your specific needs. Whether you are an engineer, a project manager, or a facility maintenance professional, understanding the key factors that influence motor selection can lead to enhanced performance and cost savings in your projects. In this guide, we will explore the most critical considerations, ensuring you have the knowledge necessary to choose the best fan motors tailored to your application.

When selecting fan motors, it's essential to understand the different types available in the market today. The global energy-efficient motor market was valued at $48.25 billion in 2023, with expectations to grow significantly, reaching approximately $84.72 billion by 2030. This growth is driven by an increasing demand for sustainable and energy-efficient technologies, pushing manufacturers to prioritize innovation in motor design and efficiency.

When choosing a fan motor, consider your specific application requirements. For instance, not all fan motors are created equal; some are designed for high-pressure systems while others suit low-noise environments. Additionally, understanding the efficiencies of different motor types—like induction, synchronous, and brushless DC motors—is crucial. Induction motors are popular for their durability, while brushless motors offer excellent efficiency and are increasingly used in various applications.

Here are a couple of tips to keep in mind: First, always check the efficiency ratings and seek motors that meet or exceed regulatory standards. Second, consider the long-term operational costs rather than just the initial purchase price, as higher efficiency may lead to significant savings on energy bills over time. Make informed decisions to ensure optimal performance and reliability in your fan motor applications.

When selecting fan motors for specific applications, several key factors must be taken into account to ensure optimal performance and efficiency. According to a recent study by the EPRI, the efficiency of fan motors can vary significantly, with high-efficiency models providing up to 30% energy savings compared to standard alternatives. One critical aspect is the motor's type; for instance, Permanent Magnet motors not only offer substantial energy savings but also have a longer lifespan, making them suitable for demanding environments.

Tip: Always verify the motor's efficiency rating against the specific requirements of your application. A motor that is too powerful may lead to unnecessary energy consumption, increasing operational costs.

Another important consideration is the operating environment. For applications exposed to extreme temperatures or corrosive substances, choosing a suitably rated motor becomes essential. The NEMA suggests that a motor with an appropriate enclosure—like TEFC (Totally Enclosed Fan Cooled)—can significantly enhance durability and reliability in harsh conditions.

Tip: Consult industry standards and seek feedback from manufacturers to choose motors that meet environmental specifications without sacrificing performance.

When selecting fan motors, a crucial decision revolves around choosing between AC and DC options. Both types have their unique advantages and operational efficiencies, but understanding their differences is essential for optimal performance. For instance, a comparative analysis shows that AC motors, known for their durability and lower maintenance needs, can operate efficiently in various industrial applications. Industry data suggests that AC motors have an average lifespan of around 29,000 hours, making them a reliable choice for long-term use.

On the other hand, DC fan motors, particularly in microgrid systems, have gained traction for their superior speed control and energy efficiency. Recent studies indicate that implementing DC microgrid systems can lead to enhanced performance over traditional AC systems, especially in applications requiring variable speed operations. Furthermore, a five-phase permanent magnet synchronous machine (PMSM) exhibits remarkable efficiency and adaptability in diverse load conditions compared to its three-phase counterparts. This comparative assessment underscores the importance of understanding the specific requirements of your application before making a final decision.

When selecting fan motors, understanding industry standards and efficiency ratings is crucial for making informed decisions. According to the U.S. Department of Energy (DOE), the installation of energy-efficient fan motors can lead to significant energy savings, potentially reducing electrical consumption by up to 30% in some applications. This highlight emphasizes the importance of selecting motors that comply with the latest efficiency standards, such as the NEMA Premium Efficiency ratings, which guarantee not only lower operational costs but also a longer lifespan for the equipment.

In addition to energy efficiency, it's essential to consider the motor's performance ratings. The American National Standards Institute (ANSI) outlines classifications for motor performance, which include torque and power density metrics. For example, motors rated under ISO 9001 are held to international quality standards, ensuring reliability and performance consistency. Utilizing fan motors that meet these stringent industry benchmarks can enhance air handling capabilities and support sustainability initiatives, ultimately leading to a more robust and efficient operation. Awareness of these standards will empower engineers and procurement professionals to select the best fan motors that align with both operational needs and environmental goals.

When selecting fan motors for your projects, avoiding common mistakes can save you time and resources. One prevalent error is underestimating the importance of motor efficiency. According to a report by the Department of Energy, electric motor systems account for approximately 70% of industrial electricity consumption. Choosing a motor with a higher efficiency rating can significantly reduce operating costs and minimize environmental impact.

Another common pitfall is neglecting to consider the operating environment. Factors such as temperature, humidity, and exposure to dust or chemicals can greatly affect motor performance and lifespan. A study by the International Energy Agency found that selecting motors without taking these conditions into account can lead to failures and unplanned downtime, costing businesses thousands in repairs and lost productivity.

**Tip:** Always consult the manufacturer’s specification sheets to ensure the motor is rated for its intended environment.

Lastly, procurement decisions can be swayed by initial costs rather than total lifecycle cost. A report from the Motor Systems Market Opportunities Assessment highlights that over 90% of a motor's total cost over its lifetime comes from energy consumption, not purchase price. Prioritize motors that may have higher upfront costs but will result in greater energy savings over time.

**Tip:** Use lifecycle cost analysis tools to assess the financial impact of your motor choices beyond just the purchase price.