In the evolving landscape of industrial applications, the selection of the right heating systems is paramount for efficiency and effectiveness. One notable solution is the Inducer Motor Furnace, which has gained traction due to its exceptional performance and energy-saving capabilities. According to a report by the U.S. Department of Energy, industrial heating accounts for nearly 30% of energy consumption in manufacturing processes, highlighting the importance of optimizing furnace operations. The Inducer Motor Furnace, with its innovative design, not only enhances heat distribution but also reduces energy waste significantly, resulting in operating cost savings that can exceed 20% per year. As industries strive to meet both efficiency demands and environmental regulations, investing in an Inducer Motor Furnace stands out as a strategic choice, bolstering productivity while adhering to sustainability goals. In this blog, we will explore the five best benefits these furnaces offer in various industrial applications.

Inducer motor furnaces present several key advantages in industrial applications, making them a valuable choice for various manufacturing processes. One significant benefit is their energy efficiency. These furnaces are designed to optimize the heat exchange process, which reduces overall energy consumption. As industries strive for more sustainable operations, utilizing inducer motor furnaces can contribute to lower emissions and a minimized carbon footprint, aligning with the latest trends toward sustainable manufacturing.

Another advantage of inducer motor furnaces is their ability to improve the quality of the final product. By ensuring uniform heating and minimizing temperature fluctuations, these furnaces help maintain the integrity of the materials being processed. This quality control is essential in sectors like steel manufacturing, where consistent results are crucial.

Tips for potential users include considering the specific industrial needs before implementation. Assessing compatibility with existing processes can enhance integration and performance. Additionally, regular maintenance of the furnace can ensure optimal operation, prolonging its lifespan and maximizing return on investment. Embracing these advanced technologies can pave the way for innovations in energy use and product quality within the industrial landscape.

This bar chart illustrates the key advantages of using inducer motor furnaces in industrial settings based on efficiency, energy savings, operational costs, maintenance, and environmental impact.

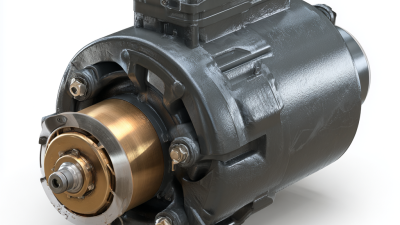

Inducer motor technology has emerged as a transformative solution for enhancing energy efficiency in industrial furnaces. By utilizing an inducer motor, these furnaces can achieve a more controlled airflow, resulting in better combustion performance. According to a report by the U.S. Department of Energy, improving combustion efficiency can potentially reduce energy consumption by up to 30%, significantly lowering operational costs for industries that rely heavily on heating processes.

One of the primary advantages of inducer motors is their ability to optimize airflow dynamics within the furnace. This optimization allows for more uniform temperature distribution, which is crucial for high-quality output in manufacturing processes. The American Society of Mechanical Engineers (ASME) has highlighted that precise temperature control is not only essential for product quality but also serves to reduce waste, thereby supporting sustainability goals within industrial operations.

Tips for achieving maximum energy efficiency with inducer motors include regular maintenance to prevent airflow obstructions and investing in automated control systems to monitor performance in real-time. Additionally, retrofitting existing equipment with inducer technology can be a wise investment, as studies show that such upgrades can enhance energy efficiency by over 20%, making them an attractive option for industrial facilities aiming to reduce their carbon footprint while remaining competitive in the market.

Inducer motor furnaces have become essential in various industrial applications, particularly due to their capability to deliver improved temperature control. This advanced technology allows for precise regulation of heat, ensuring that products are heated uniformly. By maintaining consistent thermal conditions, manufacturers can enhance product quality and reduce the risk of defects, which is crucial in industries such as metallurgy and materials processing.

The versatility of inducer motor furnaces makes them suitable for a range of industrial needs. Whether it's for annealing metals or curing materials, the ability to adapt to different temperature requirements contributes to operational efficiency. This level of control not only optimizes manufacturing processes but also minimizes energy consumption, as furnaces can operate at ideal temperatures without unnecessary fluctuations.

As industries continue to demand greater precision and efficiency, inducer motor furnaces stand at the forefront, providing solutions that meet diverse heating requirements while promoting sustainability in manufacturing practices.

In today's industrial landscape, minimizing operational costs is a top priority for businesses striving for efficiency. One effective way to achieve this is by utilizing inducer motor furnaces. By enhancing air flow and combustion efficiency, these furnaces can significantly reduce fuel consumption, ultimately leading to lower energy bills. The precise control these systems offer allows industries to optimize their operations, ensuring they achieve the best performance at the lowest cost.

In today's industrial landscape, minimizing operational costs is a top priority for businesses striving for efficiency. One effective way to achieve this is by utilizing inducer motor furnaces. By enhancing air flow and combustion efficiency, these furnaces can significantly reduce fuel consumption, ultimately leading to lower energy bills. The precise control these systems offer allows industries to optimize their operations, ensuring they achieve the best performance at the lowest cost.

Tips for implementing inducer motor solutions effectively include conducting an energy audit to identify potential savings and inefficiencies in your current system. This analysis will help you tailor the inducer motor's specifications to your operational needs, maximizing its benefits. Additionally, regular maintenance and monitoring should be established to ensure the furnace operates at optimal conditions, preventing costly downtimes and repairs.

Moreover, consider training your staff on the specific benefits and operational mechanics of inducer motors. A well-informed team can identify issues early on and make recommendations for adjustments that can enhance efficiency. By fostering a proactive operational culture, companies can capitalize further on the cost-saving capabilities of inducer motor furnaces and maintain a competitive edge in their industry.

Inducer motor furnaces are increasingly recognized for their robust durability and impressive lifespan, making them an ideal choice for various industrial applications. The design of these furnaces incorporates high-quality materials and advanced engineering techniques that enhance their resistance to wear and tear. This durability ensures they can withstand the extreme conditions often present in industrial environments, such as high temperatures and heavy usage, without compromising their performance.

Moreover, the long lifespan of inducer motor furnaces significantly reduces the frequency and costs associated with equipment replacement. Industries benefit from fewer interruptions in production due to furnace breakdowns, leading to increased operational efficiency. This longevity, combined with low maintenance requirements, means that companies can focus resources on other critical aspects of their operations instead of constantly managing repairs or replacements. Therefore, investing in inducer motor furnaces is not only a wise financial decision but also a strategic move towards enhancing productivity and reliability in industrial processes.