Access valves play a critical role in various industries, offering essential control and monitoring capabilities. According to a recent market analysis by Technavio, the global access valve market is projected to grow by 4.5% annually through 2025. This growth highlights the increasing necessity for reliable access solutions across sectors such as oil and gas, water treatment, and HVAC systems.

Choosing the right type of access valve can significantly impact system performance. Different applications demand specific characteristics from access valves, such as pressure resistance, flow rate, and durability. For instance, ball valves excel in applications requiring tight sealing and quick response. However, not all solutions are perfect. Some users report challenges in installation and maintenance, which can lead to operational inefficiencies.

Understanding diverse access valve types is not just about selecting the most popular options. It is essential to reflect on the unique needs of each application. An informed choice can enhance safety and prolong equipment life, making access valves a pivotal aspect of effective system design.

Access valves play a crucial role in various industries. They allow for easy access to pipelines, making maintenance more manageable.

Common types include ball valves,

gate valves, and check valves.

Each type has its own unique application and advantages.

Ball valves are often favored for their quick operation. They are designed for on/off control.

Gate valves, on the other hand, are ideal for regulating flow in larger pipelines. Their design allows for minimal pressure loss.

Check valves prevent backflow, ensuring that fluids flow in one direction.

Each type has its strengths and weaknesses.

Sometimes, choosing the right valve can be confusing. Consider the specific requirements of your project.

It’s essential to assess pressure,

temperature, and

fluid type for optimal performance.

Making the wrong choice can lead to costly repairs.

Every decision should be well thought out.

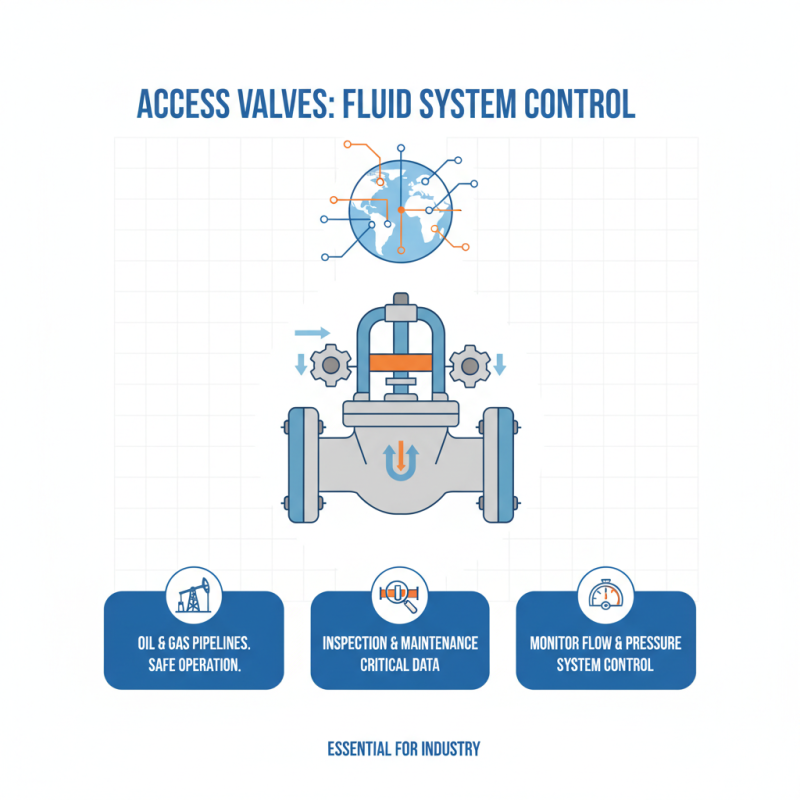

Access valves play a crucial role in various industries. They allow for inspection, maintenance, and control of fluid systems. In the oil and gas sector, access valves ensure the safe operation of pipelines. They provide necessary entry points for monitoring flow rates and pressures. Without these valves, critical data would be hard to gather.

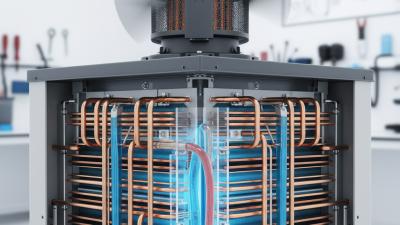

In refrigeration systems, access valves enable servicing without significant downtime. Technicians can check and refill refrigerants more efficiently. However, improper installation can lead to leaks. This risk requires continuous training for staff. In the water treatment industry, access valves facilitate the control of water flow. They allow operators to execute timely maintenance. Yet, not all facilities prioritize this step, leading to potential contamination issues.

Moreover, the HVAC industry benefits significantly from access valves. They provide access for routine checks and repairs. A small oversight could create significant operational problems. Proper usage ensures efficiency and longevity of systems, but this is often neglected. Awareness and training around access valve application are essential for sustained functionality across all sectors.

When evaluating access valves, performance is a key factor to consider. Different types of access valves serve unique applications across various industries. Each type has its strengths and weaknesses. For example, gate valves provide minimal flow resistance but can be slow to operate. On the other hand, ball valves are quicker to open and close, ideal for time-sensitive processes. However, they may not seal as effectively under certain conditions.

In practice, the choice of an access valve type often depends on the specific needs of the application. The materials used in construction can significantly impact performance and durability. For instance, metal valves may withstand higher temperatures, while plastic ones are more resistant to corrosion. Reflecting on this, one might question whether the selected valve type truly meets the long-term requirements. Costs can often dictate decisions, yet investing in a higher quality valve can prevent future issues.

Understanding the nuances of each access valve type is essential for optimal performance. However, common oversights occur, such as neglecting regular maintenance or not considering the operating environment. These factors can lead to underperformance and increased operational costs. A focus on thorough analysis and proper valve selection can lead to improved outcomes, but it requires ongoing evaluation and refinement.

| Valve Type | Material | Pressure Rating | Temperature Range | Applications |

|---|---|---|---|---|

| Globe Valve | Carbon Steel | Class 150 - 2500 | -20°C to 425°C | Flow Regulation, Isolation |

| Gate Valve | Stainless Steel | Class 150 - 600 | -20°C to 260°C | On/Off Control, Pipeline Isolation |

| Ball Valve | Brass | Class 150 - 600 | -30°C to 180°C | Quick Shutoff, General Services |

| Check Valve | Cast Iron | Class 125 - 250 | -10°C to 180°C | Prevent Backflow, Water Systems |

| Butterfly Valve | PVC | Class 150 | -10°C to 70°C | Flow Regulation, Waste Water |

When selecting an access valve, installation considerations play a crucial role in performance and longevity. Different valve types require distinct installation methods. For instance, ball valves need a straight pipe run before and after installation. This helps maintain optimal flow conditions and minimizes turbulence. Misalignment during installation can lead to increased wear and poor sealing.

Proper sealing is vital. Gaskets ensure leak-proof performance. A study from the American Society of Mechanical Engineers (ASME) found that incorrectly installed gaskets account for nearly 30% of valve-related failures. Each valve type dictates unique gasket requirements based on pressure and medium. Take time to review specifications thoroughly.

Space limitations can complicate the installation process. Some areas require compact valves. Others can accommodate larger, more robust designs. Calculating available space is essential to avoid late-stage modifications. Moreover, environmental factors like temperature and pressure fluctuations can affect valve performance. A well-documented guide by the Valve Manufacturers Association (VMA) notes that understanding these conditions adds value to your installation process. Each decision impacts the operational efficiency of access valves in the long run.

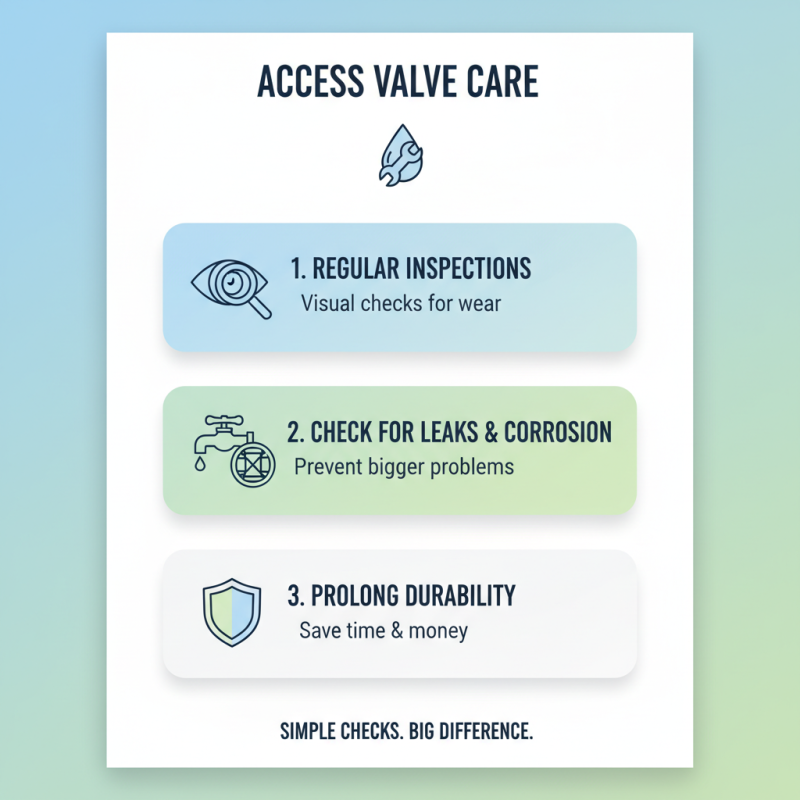

Proper maintenance of access valves is crucial for their durability. Regular inspections can help identify wear and tear. Check for leaks and corrosion regularly. These issues can lead to bigger problems if left unattended. Simple visual checks can make a significant difference. It’s easy to overlook minor leaks, but they can escalate quickly.

Cleaning access valves is another key practice. Dirt and debris can hinder their operation. Use appropriate tools to clean the surfaces without causing damage. Ensure seals remain intact. Replace any worn seals promptly to prevent failures. Maintenance schedules can sometimes be hard to stick to; set reminders to keep on track.

Don't ignore the importance of lubricant. Apply it sparingly to moving parts. Too much can attract dirt, leading to further issues. Learn from past mistakes. If maintenance was neglected, assess what went wrong. This helps in developing better practices in the future.