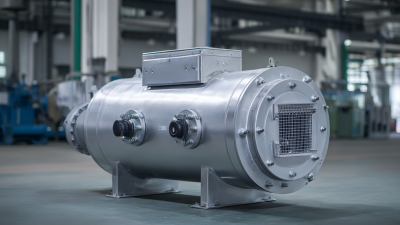

In the world of compressed air systems, ensuring the highest quality and efficiency of operation is paramount. An essential component in maintaining optimal performance is the Air Compressor Filter Dryer. As industry expert Dr. Henry P. Cline, a leading figure in compressed air technology, states, "The effectiveness of an air compressor significantly hinges on the purity of the air it produces, and that’s where the Air Compressor Filter Dryer comes into play." This statement underscores the crucial role of filter dryers in enhancing the reliability and longevity of air compressor systems.

Air Compressor Filter Dryers are designed to remove moisture, contaminants, and oil from compressed air, thereby preventing damage to machinery and reducing maintenance costs. Without such protection, businesses face the risk of costly downtime due to equipment failures linked to dirty or wet air systems. By investing in an Air Compressor Filter Dryer, companies ensure a clean, dry air supply that contributes to improved equipment efficiency and better overall operational performance.

As businesses strive for excellence in their operations, understanding the importance of an Air Compressor Filter Dryer becomes indispensable. With the right filtration and drying system in place, organizations can achieve optimal performance, safeguard their investments, and maintain a competitive edge in their respective sectors.

Air compressor filter dryers play a crucial role in maintaining the efficiency and longevity of your air compressor system. These devices are designed to remove moisture and contaminants from compressed air, which is essential for ensuring optimal performance. Moisture in compressed air can lead to rust, corrosion, and operational inefficiencies, which can significantly affect the quality of the end products and may cause costly downtime. By incorporating a filter dryer into your compressor setup, you can protect downstream equipment and ensure consistent air quality.

Understanding the functionality of air compressor filter dryers is fundamental for any operator. These systems typically work by first filtering out particulates and then utilizing various drying methods, such as refrigeration or desiccant drying, to eliminate moisture. This process not only safeguards the machinery from water damage but also enhances the performance of pneumatic tools and equipment that rely on clean, dry air. As a result, investing in a reliable filter dryer is essential for achieving peak operational efficiency and reducing maintenance costs over time.

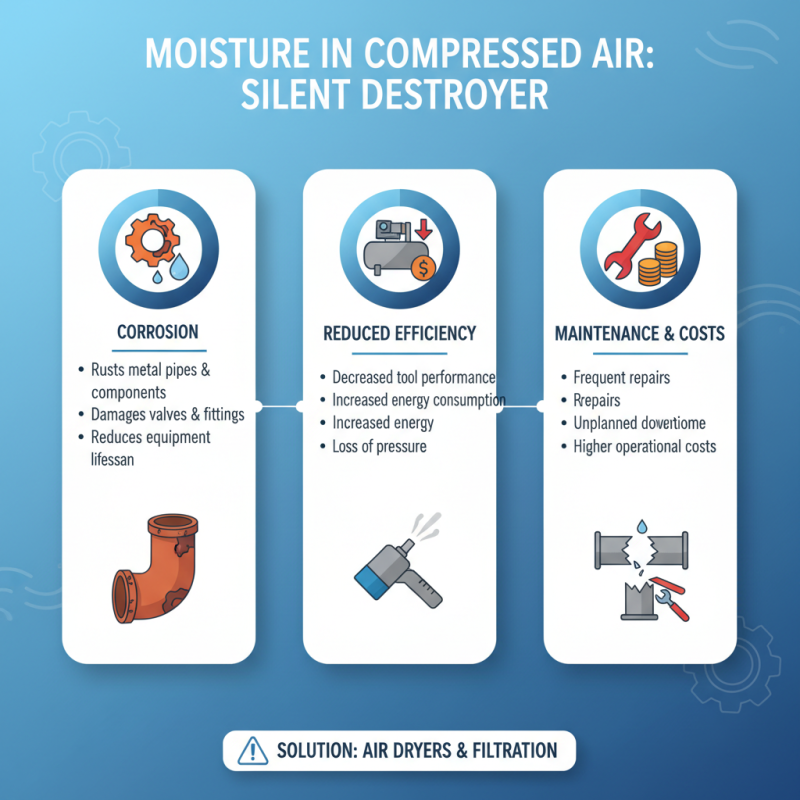

Moisture in compressed air systems can lead to a variety of common yet significant issues that affect operational efficiency and equipment lifespan. One of the primary concerns is corrosion. When water accumulates in the air lines, it can cause rust to form in various components, leading to costly damage and unscheduled maintenance downtime. This corrosive effect not only impacts valves and fittings but can also damage pneumatic tools and machinery, resulting in decreased productivity and higher repair costs.

Another issue related to moisture is the formation of ice, particularly in colder environments. Ice buildup can obstruct airflow and create pressure drops in the system, which hampers performance and can cause equipment malfunction. Additionally, moisture can lead to the growth of bacteria and mold within air lines, potentially contaminating products in industries such as food and pharmaceuticals. The presence of water vapor can also affect the quality of finished products, leading to inconsistency and potential product recalls. Businesses relying on compressed air systems for their operations must recognize these risks and invest in an air compressor filter dryer to maintain optimal performance and reliability.

Installing an air compressor filter dryer is essential for maintaining optimal performance in any compressed air system. One of the primary benefits is the removal of moisture from the air supply. Moisture can lead to rust and corrosion in air tools and equipment, diminishing their lifespan and efficiency. By incorporating a filter dryer, you significantly reduce the risk of water-related damage, ensuring that your tools operate smoothly and effectively.

Another key advantage of having a filter dryer is the enhancement of air quality. Contaminants such as dirt, oil, and water vapor can compromise the integrity of your applications. A filter dryer helps to eliminate these impurities, resulting in cleaner, drier air that contributes to improved product consistency and quality. This is especially crucial in industries like automotive or manufacturing, where precision and reliability are paramount. By investing in a filter dryer, you not only protect your equipment but also uphold the standards of quality in your operations.

| Dimension | Value |

|---|---|

| Average Moisture Content in Compressed Air | 70-90% RH |

| Reduction in Corrosion | Up to 80% |

| Increase in Equipment Lifespan | 20-30% |

| Energy Savings | 10-15% |

| Air Quality Improvement | Significant |

| Maintenance Frequency Reduction | 50% |

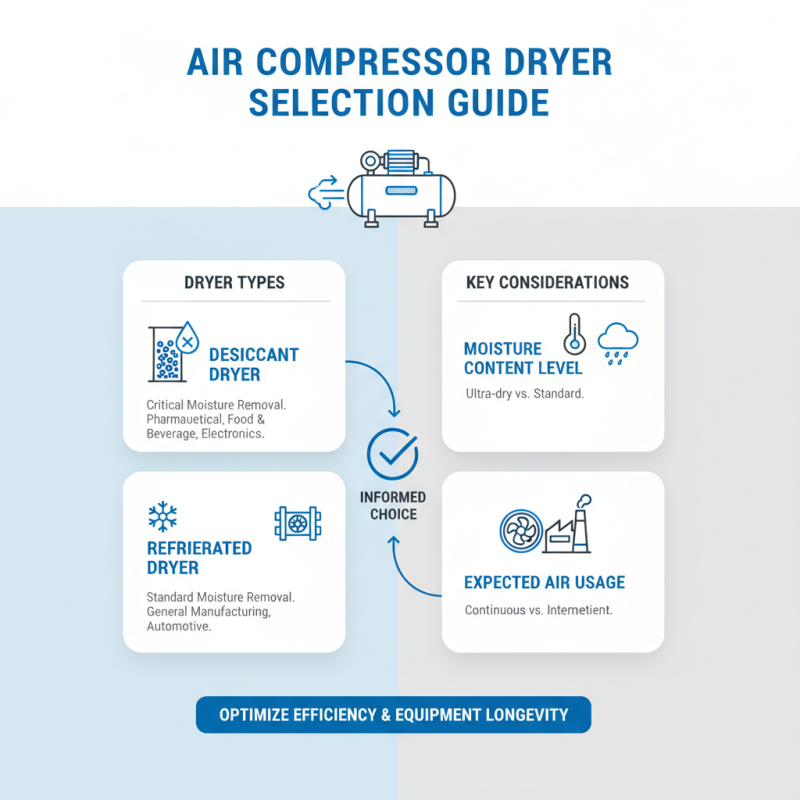

When selecting the right type of air compressor filter dryer for your needs, it's essential to consider the specific requirements of your application. Different industries have varying demands for compressed air quality, which can significantly impact the efficiency and longevity of your equipment. For instance, a desiccant dryer might be ideal for environments where moisture removal is critical, while a refrigerated dryer may suffice for less stringent applications. Understanding the moisture content levels and the expected air usage can help in making an informed choice.

Another important factor is the flow rate of your air compressor system. The filter dryer must be capable of handling the maximum flow without causing pressure drops that could affect your operations. Additionally, consider the installation space available, maintenance needs, and how easy it is to replace components when selecting a dryer. By evaluating these elements, you can ensure that your air compressor filter dryer will perform optimally and meet your specific operational requirements, leading to enhanced production efficiency and equipment reliability.

Maintaining optimal performance of air compressor filter dryers is essential for ensuring the longevity and efficiency of your compressed air system. Regular maintenance not only helps in preventing costly downtime but also improves the overall quality of the air supplied in industrial applications. According to a report by the Compressed Air and Gas Institute, improper maintenance can lead to an increase in operational costs by 20-30% due to inefficiencies and equipment failures. Therefore, implementing a robust maintenance strategy is critical.

One of the key tips for maintaining filter dryers is to schedule regular inspections and replacements of filters. It is recommended to check filters every 2-3 months depending on the operational conditions and dust levels in the environment. A study from the U.S. Department of Energy indicates that replacing clogged filters can increase system efficiency by up to 15%, which translates to significant energy savings over time. Additionally, monitoring the dew point temperature regularly ensures that moisture is effectively managed, preventing corrosion and damage to downstream equipment.

Another important aspect of filter dryer maintenance is the regular draining of condensate. Automatic drain valves can improve the system’s reliability by removing accumulated moisture, but manual checks should also be performed. Neglecting to drain condensate could result in water contamination, which is detrimental to both equipment and product quality. Industry standards recommend maintaining a drain schedule based on the operating environment, typically ranging from daily to weekly intervals. This proactive approach not only maximizes the performance of filter dryers but also extends the lifespan of the entire compressed air system.