In the realm of industrial processing, the pursuit of efficient drying solutions has never been more critical. As we look towards 2025, the filtering capabilities of modern Filter Dryer technologies are evolving rapidly, offering unprecedented efficiency and effectiveness. According to Dr. Emily Carter, a renowned expert in the field of filtration technologies, "Filter Dryers are revolutionizing the way industries approach product drying, allowing for higher yields and better quality." This insight emphasizes the growing demand for advanced drying methods that not only enhance productivity but also adhere to stringent quality standards.

The efficiency of a Filter Dryer is pivotal in various sectors, from pharmaceuticals to food processing, where the right drying technique can significantly impact the final product. As users become increasingly aware of the benefits associated with optimized drying processes, exploring the best Filter Dryer options available becomes paramount. This article will delve into the top Filter Dryer solutions anticipated for 2025, offering insights into their operational advantages, energy efficiency, and how they can cater to diverse industrial needs. By understanding these options, businesses can make informed decisions that align with their goals for productivity and sustainability.

In 2025, filter dryer technologies have evolved significantly, addressing both efficiency and sustainability in industrial processes. The global market for filter dryers is projected to reach $2.5 billion, according to recent industry reports. This growth is driven by the increasing demand for advanced drying solutions in pharmaceuticals, food and beverage, and chemical manufacturing sectors. With stringent regulations on waste management and environmental impact, industries are shifting towards filter dryers that not only provide consistent drying results but also minimize energy consumption.

One prominent development in filter dryer technology is the integration of automation and real-time monitoring systems. These advancements enable precise control of drying parameters, such as temperature and pressure, which significantly improve batch consistency and product quality. Additionally, energy-efficient designs, such as those employing heat recovery systems, can reduce the overall energy footprint of drying processes by up to 30%. As industries prioritize sustainability and operational efficiency, these cutting-edge technologies are poised to play a crucial role in enhancing productivity while meeting regulatory standards.

Moreover, the surge in demand for filter dryers can also be attributed to their versatility in handling various materials, ranging from specific chemical compounds to bulk solids. The ability to adapt to diverse operational environments further cements their position as a preferred choice for manufacturers seeking reliable and efficient drying solutions. With ongoing research and development, the landscape of filter dryer technology in 2025 promises to focus on innovation while aligning with the industry's growing emphasis on ecology and performance.

| Type of Filter Dryer | Max Capacity (kg/h) | Energy Efficiency (%) | Main Features | Typical Applications |

|---|---|---|---|---|

| Nutsche Filter Dryer | 500 | 85 | High solid-liquid separation, low residual moisture | Pharmaceuticals, Chemicals |

| Plate Filter Dryer | 300 | 90 | Modular design, compact footprint | Food Industry, Fine Chemicals |

| Conical Screw Dryer | 400 | 80 | Gentle mixing and drying, low heat sensitivity | Petrochemicals, Polymers |

| Vacuum Filter Dryer | 600 | 75 | Reduced oxidation risk, solvent recovery | Chemical Processing, Waste Treatment |

| Drum Filter Dryer | 200 | 70 | Continuous processing, versatile drying modes | Pharmaceuticals, Food Products |

When selecting a top filter dryer for efficient drying solutions, several key features should be prioritized to ensure optimal performance. First and foremost, the drying capacity is critical. A dryer with appropriate capacity will determine the volume of material it can handle effectively, which directly influences operational efficiency and productivity. Additionally, look for dryers with adjustable settings; flexibility in temperature and drying time allows for tailored processing of various materials, leading to consistently high-quality outputs.

Another essential feature to consider is the filtration efficiency of the system. A high-quality filter dryer should possess a robust filtration mechanism that ensures effective removal of solvent vapors and particulates, preventing contamination and enhancing product purity.

Furthermore, energy efficiency should not be overlooked; choosing a model with advanced energy-saving technology can lead to significant cost reductions in the long run. Lastly, ease of maintenance and user-friendly controls can greatly improve operational workflow, minimizing downtime and ensuring that the equipment can be reliably used across different processing environments.

In 2025, the filtration and drying industry is witnessing remarkable advancements, with brands striving to enhance efficiency and sustainability in their products. A recent industry report indicates that the global market for filter dryers is projected to grow at a CAGR of 5.8% through the next five years, driven by increasing demand across pharmaceuticals, food processing, and chemical manufacturing. Leading brands are innovating to provide solutions that not only reduce drying times but also lower energy consumption, essential in meeting regulatory and environmental standards.

When comparing the top models in 2025, one key feature to look for is the integration of smart technology. Devices equipped with real-time monitoring systems can enhance operational efficiency by adjusting parameters based on humidity and pressure levels. Additionally, these smart systems can provide predictive maintenance alerts, thus minimizing downtime. Energy efficiency ratings are critical as well; selecting models that exceed industry standards can result in significant long-term savings.

Tips: Always assess the total cost of ownership when selecting a filter dryer, as initial investment should be weighed against performance and maintenance costs. It's also beneficial to evaluate user reviews and case studies to gauge real-world performance. Lastly, consider the ease of use and availability of technical support, as these factors can significantly impact operational efficiency.

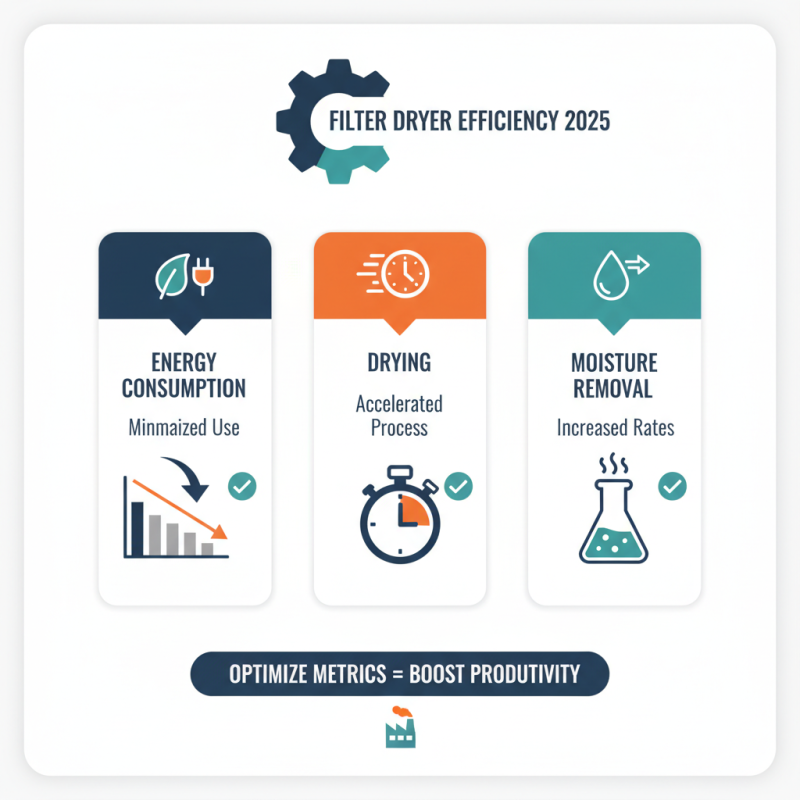

When evaluating filter dryers in 2025, efficiency metrics play a crucial role in determining the ideal drying solution for industrial applications. Key factors to consider include energy consumption, drying time, and moisture removal rates. An efficient filter dryer not only minimizes energy usage but also accelerates the drying process, leading to increased productivity. Companies should focus on optimizing these metrics to enhance overall operational performance.

Tips for selecting the right filter dryer include assessing the specific moisture content of your material and understanding the thermal characteristics required for effective drying. Implementing advanced control systems can also significantly improve drying efficiency by allowing operators to monitor and adjust parameters in real-time. Additionally, looking for technologies that incorporate heat recovery systems can further reduce energy costs while maintaining optimal drying conditions.

Another important metric is the filter’s cleaning efficiency, which directly impacts maintenance costs and downtime. A well-designed filter dryer should offer easy access for cleaning and maintenance, thus ensuring consistent performance over time. Choosing models with automated cleaning systems can greatly enhance operational efficiency, as they reduce the need for manual intervention and prolong the lifespan of the equipment.

As industries shift towards more sustainable practices, the innovations in filter dryer technology are rapidly advancing to meet both efficiency and environmental goals. The increasing demand for energy-efficient and cost-effective drying solutions has led to a significant rise in market research. According to a report by MarketsandMarkets, the filter dryer market is projected to grow from $2 billion in 2020 to $4 billion by 2025, driven by stringent regulations on waste management and the need for enhanced operational efficiency.

The focus on sustainability is pushing manufacturers to develop filter dryers that minimize energy consumption and reduce the environmental footprint. For instance, the implementation of heat recovery systems in filter dryers can lead to reductions in energy use by up to 30%. Additionally, advancements in automation and control technologies enable real-time monitoring and optimization of drying processes, ensuring that resources are used efficiently while maintaining product quality.

Tips: When considering filter dryer options for your facility, prioritize models that offer built-in energy-saving features and automation capabilities. Engaging in regular maintenance is also crucial; it can enhance the longevity of the equipment and maximize efficiency. Finally, investing in training for staff on the best operating practices can significantly impact the efficacy of drying operations and overall sustainability efforts.