Choosing the right equipment for your industrial needs is crucial, and one of the most important tools in ensuring compressed air quality is an Inline Air Dryer. As businesses strive for efficiency and reliability, the role of a high-performing air dryer cannot be overstated. In the quest for optimal air quality, these systems not only help in removing moisture from compressed air but also protect valuable machinery and enhance overall productivity.

In 2025, the variety of Inline Air Dryers available on the market is immense, each boasting unique features designed to cater to different operational requirements. With advancements in technology and a deeper understanding of industrial needs, selecting the best option can seem daunting. This guide aims to simplify your decision-making process, presenting you with the top five Inline Air Dryers that stand out in terms of performance, efficiency, and suitability for various applications.

By the end of this guide, you will be equipped with the knowledge needed to identify the Inline Air Dryer that best meets your specific needs, ensuring that your operations not only run smoothly but also remain cost-effective. Join us as we delve into the essential factors to consider and highlight our top picks for 2025.

When selecting the best inline air dryer for your needs, understanding the key features is essential for making an informed choice. Inline air dryers come with various functionalities that can significantly affect performance and efficiency. One of the primary features to consider is the drying capacity, which should match your air compressor's specifications. Additionally, evaluate the drying method employed by the unit, whether it's a refrigerant, desiccant, or heated dryer, as this will influence the dew point and the effectiveness of moisture removal.

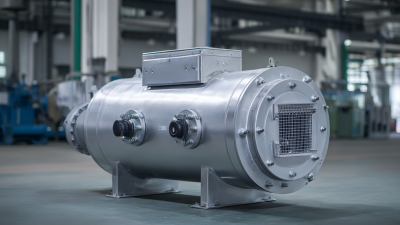

Another crucial aspect is the ease of maintenance and installation. Look for models that offer user-friendly controls and require minimal upkeep. The durability and build quality are also significant factors; opting for units with corrosion-resistant materials can ensure longer life and better reliability. Lastly, consider the energy efficiency rating to minimize operational costs. By focusing on these key elements, you can find an inline air dryer that not only meets your specific needs but also operates effectively over time.

When selecting the right inline air dryer for your application, it's essential to understand the various technologies available. The two primary types of inline air dryers are refrigerated and desiccant dryers. Refrigerated dryers are generally more energy-efficient and suitable for moderate applications where moisture control isn't exceptionally rigorous. In contrast, desiccant dryers excel in environments with stringent moisture requirements, often reducing moisture levels to -40°F or lower, making them ideal for sensitive processes in industries like pharmaceuticals and food processing.

When considering compressed air flow measurement, several criteria come into play. Key factors include the flow rate, pressure drop, and the temperature of the compressed air. Systems typically require a flow rate of at least 10% of the maximum flow to operate efficiently. According to industry reports, maintaining a pressure drop below 5 psi is crucial for optimizing performance and energy efficiency. Moreover, knowing the temperature range of your application can help determine the most effective air dryer type.

**Tips:** Ensure regular maintenance of your inline air dryer to prevent moisture build-up and maintain optimal performance. Always keep an eye on your air quality standards; monitoring the dew point regularly can help detect issues before they escalate. Lastly, consider the energy costs associated with each dryer type to align your choice with both performance needs and budget constraints.

When selecting an inline air dryer, evaluating its capacity and efficiency is crucial to ensure optimal performance for your specific needs. The size of the air dryer directly influences its drying capabilities and the overall efficiency of your compressed air system. According to industry reports, a properly sized air dryer can reduce energy consumption by up to 20%, significantly lowering operational costs. It is recommended that users calculate their maximum air flow requirements, usually measured in cubic feet per minute (CFM), and select a dryer that meets or exceeds this demand.

In addition to flow rate, efficiency ratings such as the Energy Efficiency Ratio (EER) play a vital role in determining the right inline air dryer. A study conducted by the Compressed Air and Gas Institute (CAGI) found that models with higher EER ratings use less energy for the same drying capacity, resulting in substantial savings over time. As such, opting for a unit with a balanced capacity-to-demand ratio not only enhances performance but also contributes to sustainability efforts by minimizing wasteful energy use.

When selecting an inline air dryer, two critical factors to consider are maintenance and durability, which significantly influence both longevity and performance. A recent report by the Compressed Air and Gas Institute (CAGI) indicates that regular maintenance can increase the lifespan of air dryers by up to 50%. This proactive approach not only ensures optimal performance but also reduces the risk of costly downtime caused by equipment failure. Routine checks, including filter replacements and system inspections, are essential to maintain the efficiency of the dryer, preserving both the quality of compressed air and the longevity of the unit itself.

Moreover, the materials used in constructing an inline air dryer play a pivotal role in its durability. According to the latest analysis from the American Society of Mechanical Engineers (ASME), dryers made from corrosion-resistant materials such as stainless steel can significantly extend service life, often exceeding 15 years under proper maintenance conditions. Additionally, features such as reinforced connections and quality seals help to minimize wear and tear, ultimately improving the dryer’s performance. Understanding these factors not only aids in choosing the right model but also ensures that investments in air drying technology pay off in reduced operational costs and enhanced reliability over time.

| Model | Flow Rate (CFM) | Max Pressure (PSI) | Temperature Range (°F) | Maintenance Frequency (months) | Expected Lifespan (years) | Energy Efficiency (kWh/year) | Price Range ($) |

|---|---|---|---|---|---|---|---|

| Model A | 10 | 100 | 33-120 | 6 | 5 | 800 | 200-300 |

| Model B | 15 | 120 | 30-150 | 12 | 6 | 900 | 350-450 |

| Model C | 20 | 150 | 32-140 | 9 | 7 | 950 | 400-500 |

When selecting an inline air dryer, the cost is often a significant factor for many businesses, but it should be balanced with quality performance. A recent report by the Compressed Air & Gas Institute indicates that while lower-cost models may seem appealing, they can often lead to higher long-term operational costs due to lower efficiency and increased maintenance needs. Investing in a quality inline air dryer can reduce energy consumption by up to 30%, which can result in savings that significantly offset the initial higher purchase price.

Additionally, a study from the Air Conditioning, Heating, and Refrigeration Institute highlights that durable air dryers can have a lifespan exceeding 15 years, compared to the 5-7 years typical of cheaper alternatives. This longevity means fewer replacements, lower installation costs, and reduced downtime, ultimately enhancing productivity. By analyzing the total cost of ownership—which encompasses purchase price, maintenance, and energy consumption—businesses can make informed decisions that ensure both financial and operational efficiency in their inline air dryer selection.