01

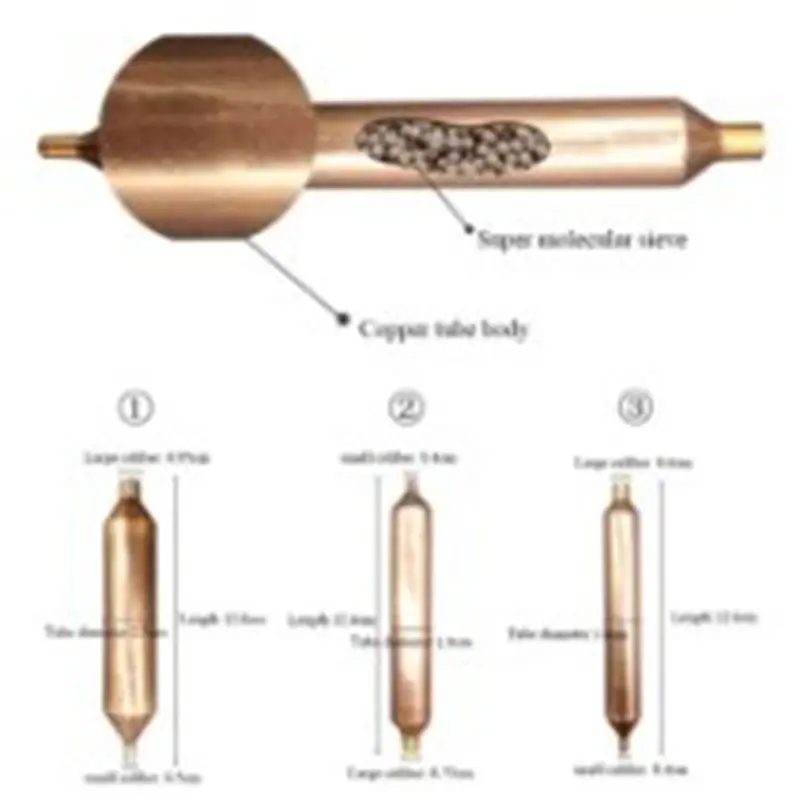

All Sizes Copper Filter Drier for Air Conditioners and Refrigerators

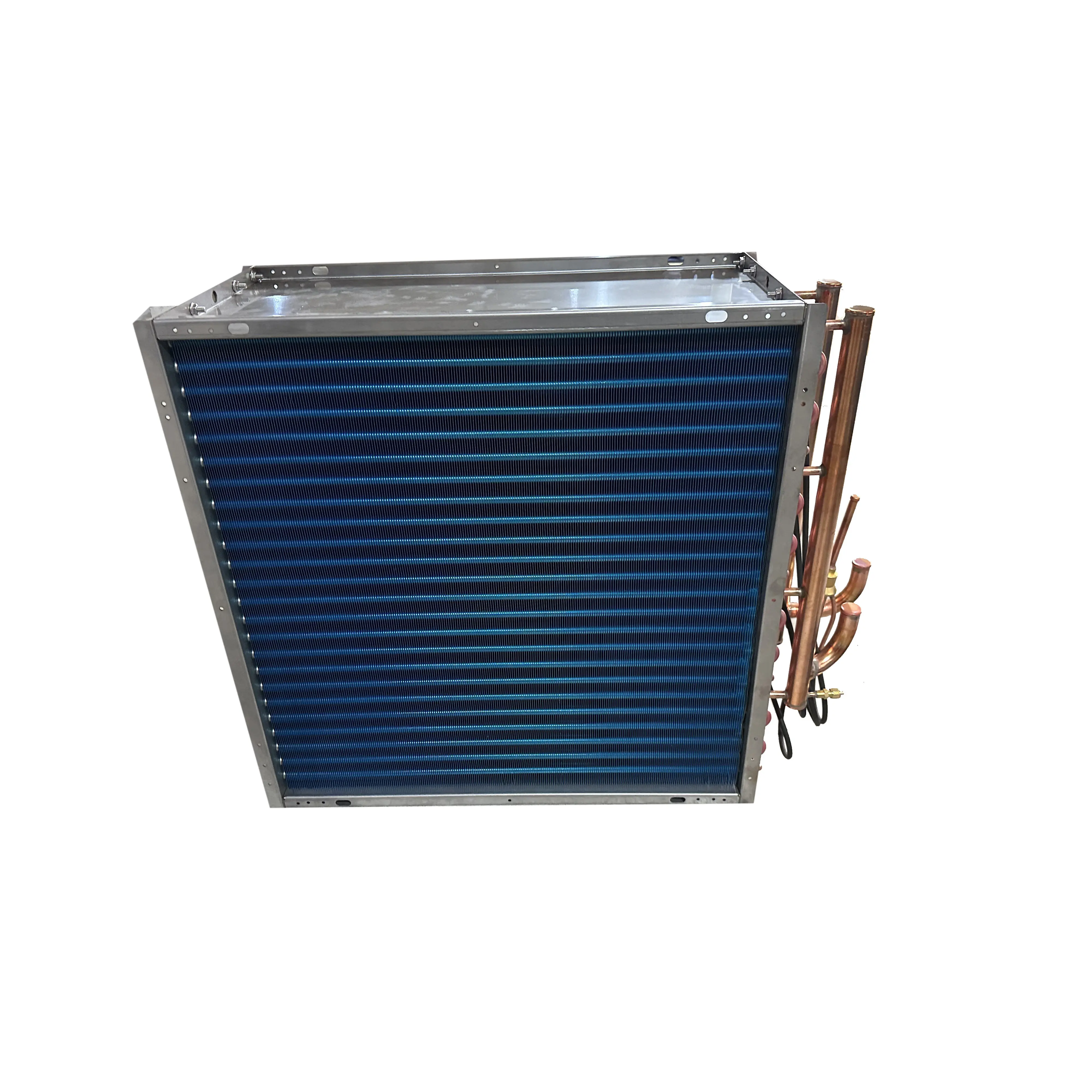

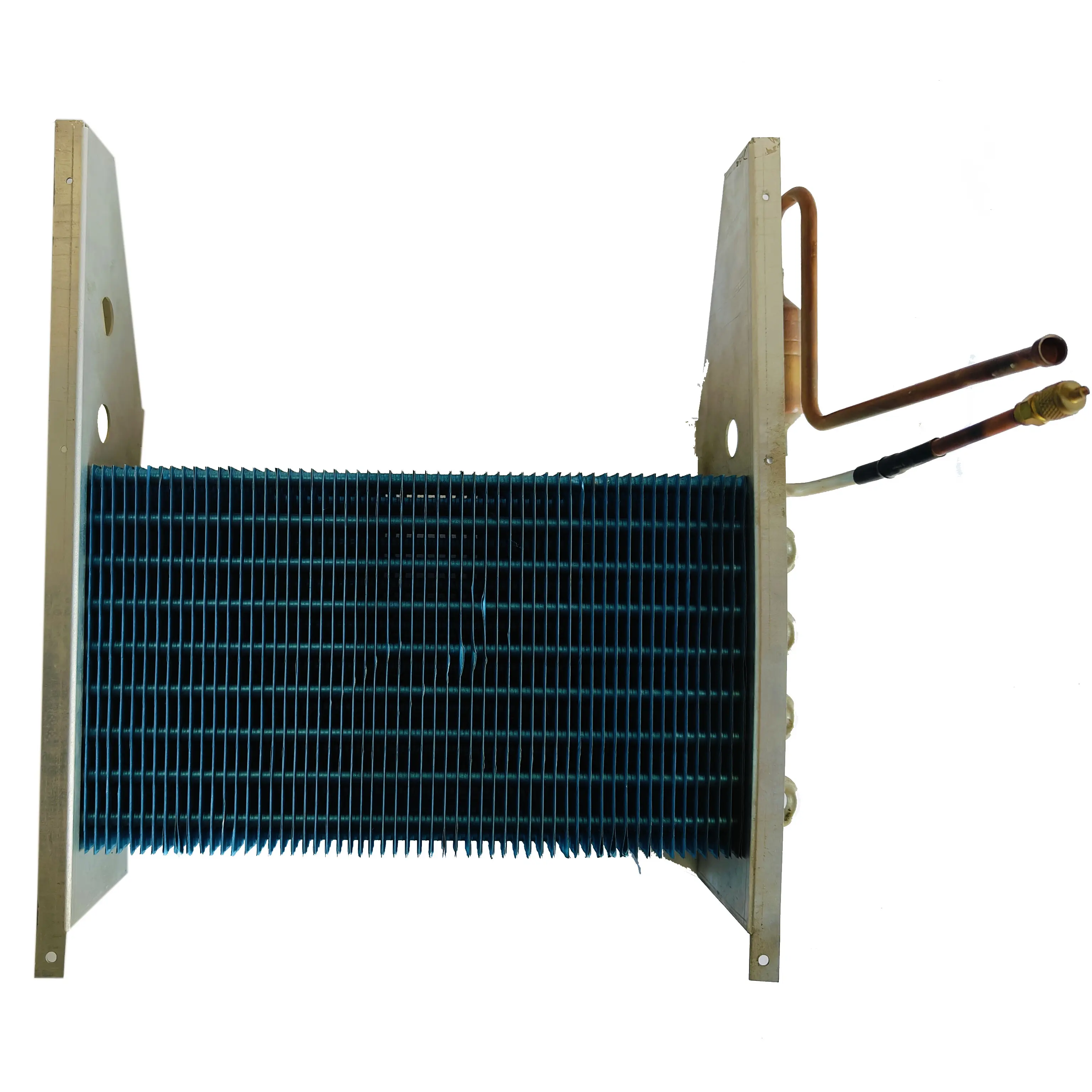

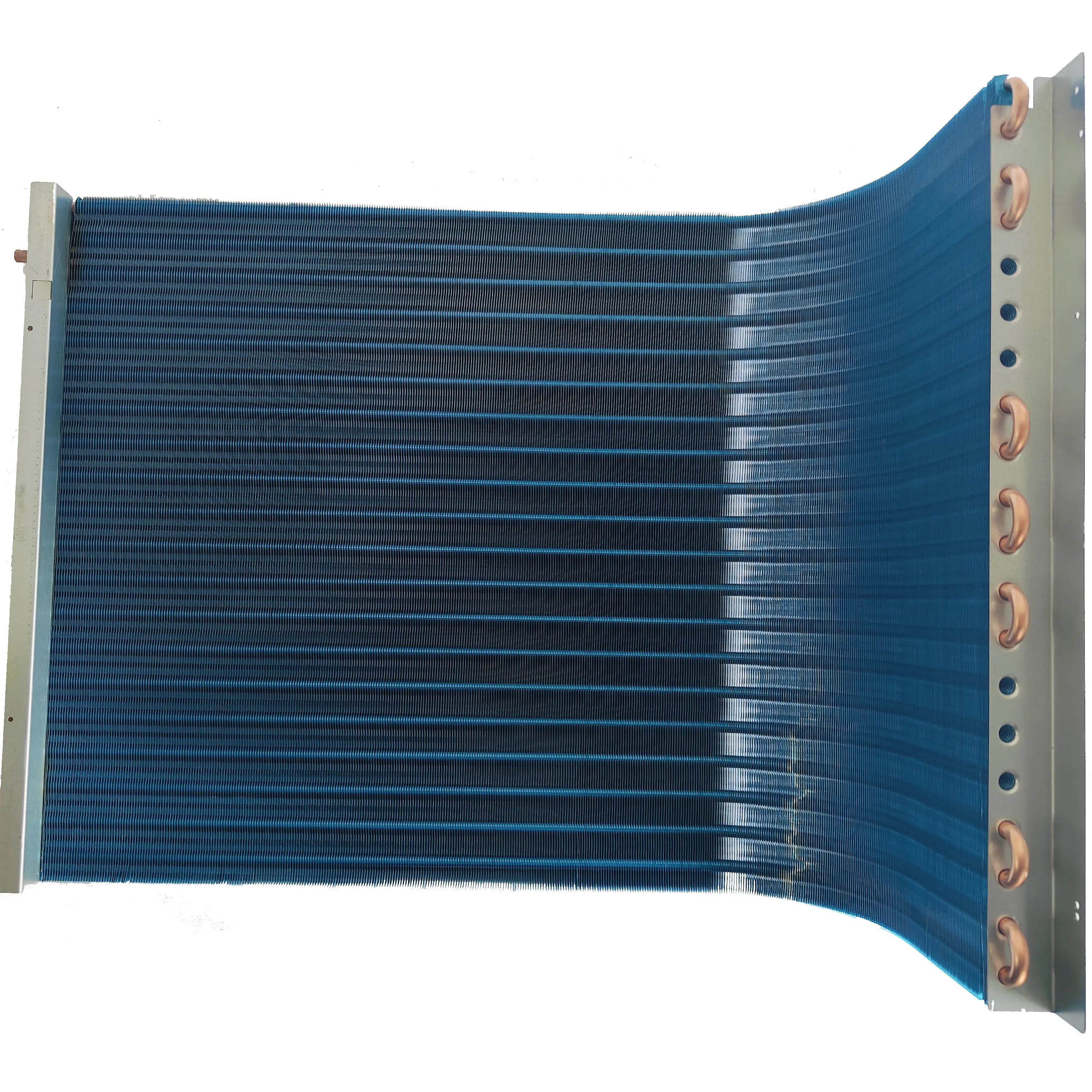

Product DisplaySENJUN

PRODUCT DESCRIPTIONSENJUN

|

MODEL |

Molecular Sieves +5%,-0% |

Body diameter ±0.10mm |

Overall Length ±2mm |

Screen Depth ±2mm |

|

SJ1 |

5 gr |

16 |

80 |

24 |

|

SJ2 |

7 gr |

16 |

90 |

24 |

|

SJ3 |

10 gr |

16 |

115 |

24 |

|

SJ4 |

10 gr |

19 |

100 |

26 |

|

SJ5 |

12 gr |

19 |

105 |

26 |

|

SJ6 |

13 gr |

19 |

110 |

26 |

|

SJ7 |

15 gr |

19 |

115 |

26 |

|

SJ8 |

18 gr |

19 |

128 |

26 |

|

SJ9 |

20 gr |

19 |

141 |

26 |

|

SJ10 |

20 gr |

24 |

120 |

28 |

|

SJ11 |

25 gr |

24 |

125 |

28 |

|

SJ12 |

30 gr |

24 |

140 |

28 |

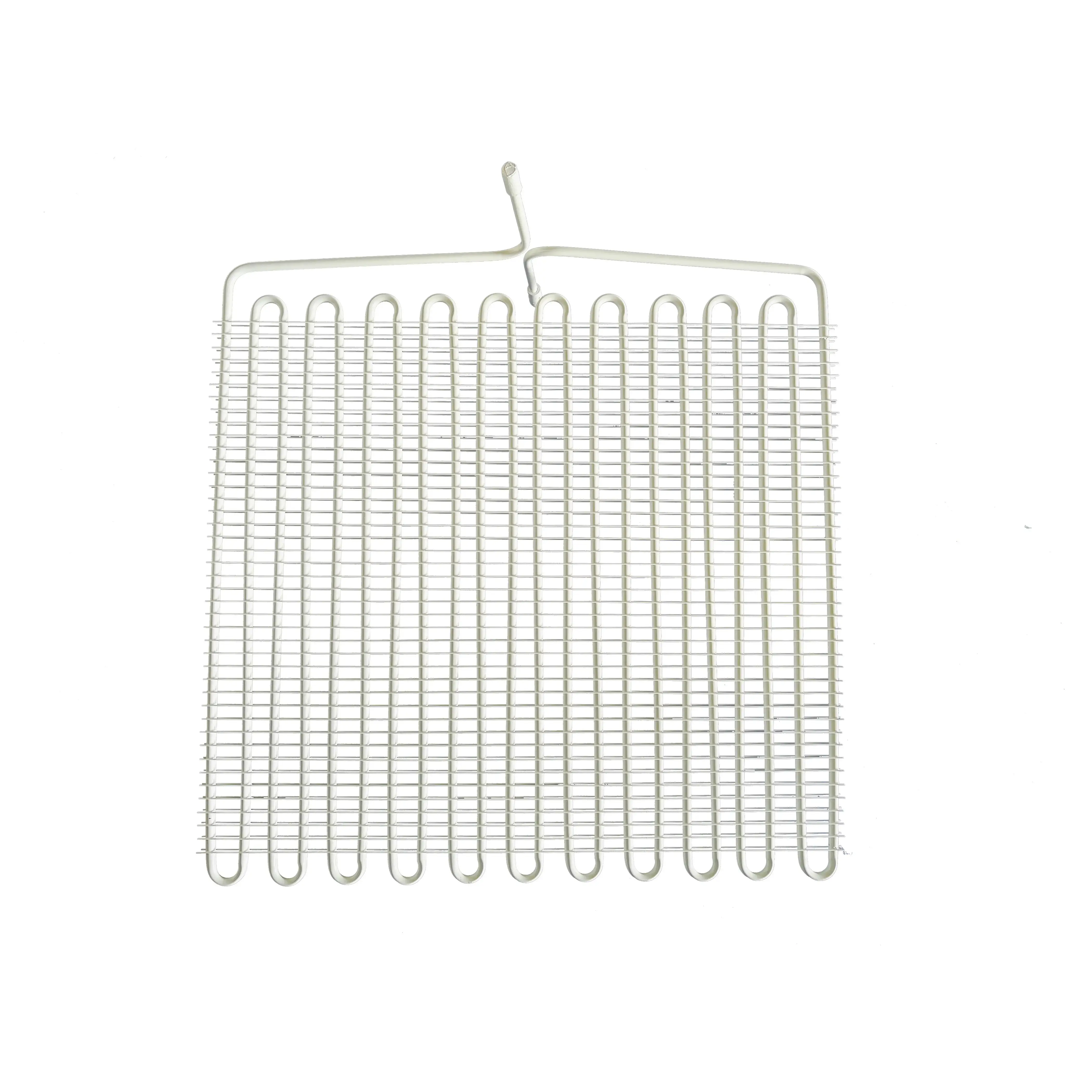

Copper filter drier is an important component in air conditioners and refrigerator refrigeration systems. It mainly plays the role of filtering and drying. In the refrigeration cycle, the refrigerant will circulate, and the copper dry filter can block impurities in the system, such as metal shavings, oxides and other solid particles, to prevent them from entering key components such as the compressor or expansion valve, thus Prevent component damage and ensure normal operation of the refrigeration system. At the same time, it can also absorb moisture in the refrigerant. The copper filter drier has good thermal conductivity and corrosion resistance, and can adapt to the working environment of the refrigeration system.

-

1. Application Scenario in RefrigeratorIn the refrigeration system of a direct cooling refrigerator, a copper filter drier is installed between the condenser and the capillary tube. The refrigerant flows out of the condenser and enters the copper filter drier. Since the evaporator of a direct-cooled refrigerator cools the inside of the refrigerator by natural convection, the purity of the refrigerant is particularly important. Copper filter drier here mainly plays two roles: one is to filter the refrigerant in the process of circulating impurities, such as the compressor operation of the metal chips, pipeline welding process residual welding slag and so on. These impurities, if they enter the capillary tube, may cause blockage, affecting the flow of refrigerant, which in turn leads to poor refrigerator cooling effect. The second is to absorb the moisture in the refrigerant, because in a low-temperature environment, the moisture may freeze and cause ice blockage in the capillary tube. For example, when the refrigerator is used in a humid environment, the refrigerant is prone to absorbing moisture, and the copper filter drier can effectively prevent this from happening and ensure that the refrigerator cools properly.

-

2. Application scenarios in air conditioners:In the refrigeration system of air conditioners, copper filter dryers are generally installed after the condenser and before the throttling device (such as capillary tube or electronic expansion valve). When the air conditioner is running, the compressor compresses the gaseous refrigerant into a high-temperature and high-pressure state, and then sends it to the condenser for heat dissipation. The refrigerant from the condenser enters the copper filter drier. It first filters out impurities in the refrigerant, such as metal particles produced by compressor wear, dust mixed in the air, etc. If these impurities enter the throttling device, they may cause blockage and affect the refrigeration and dehumidification functions of the air conditioner. Secondly, it absorbs moisture from the refrigerant and prevents ice blockage from forming on the evaporator. Especially in humid weather conditions, when the air conditioner runs frequently, the copper drying filter can effectively ensure the normal operation of the air conditioner and provide a comfortable indoor temperature and humidity environment.

-

3.Small refrigeration equipmentThe refrigeration system of a small ice machine has high requirements on the purity of the refrigerant. The copper filter dryer can filter impurities and ensure that the evaporator of the ice machine can absorb heat efficiently, thereby improving ice making efficiency. At the same time, it can also absorb moisture to avoid ice blockage during the ice making process, ensuring the quality of the ice cubes and the normal operation of the ice machine.